Battery fabrication sheet winding integrated machine for pasting protection glue at high speed

A technology of protective glue and all-in-one machine, which is applied in the manufacture of electrolyte batteries, circuits, primary batteries, etc., to achieve reliable product yield, save space, and convenient and quick sticking of protective glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

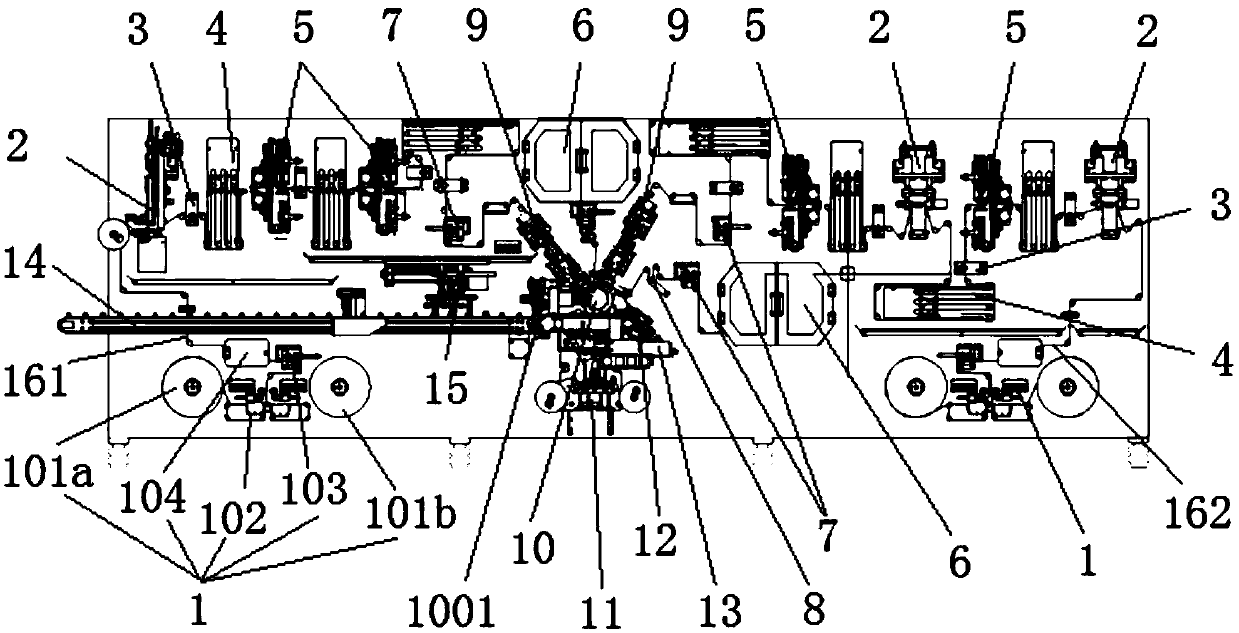

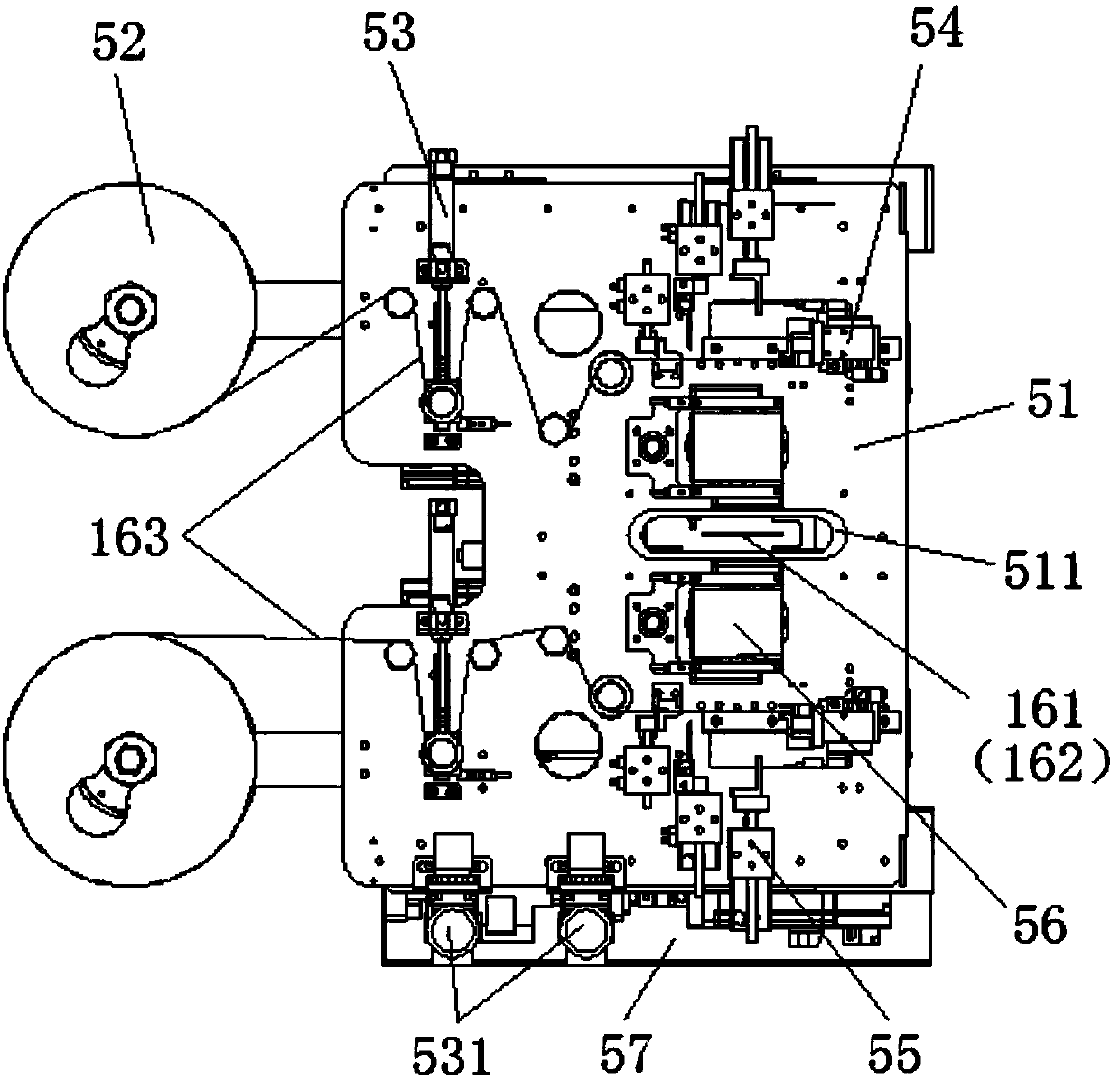

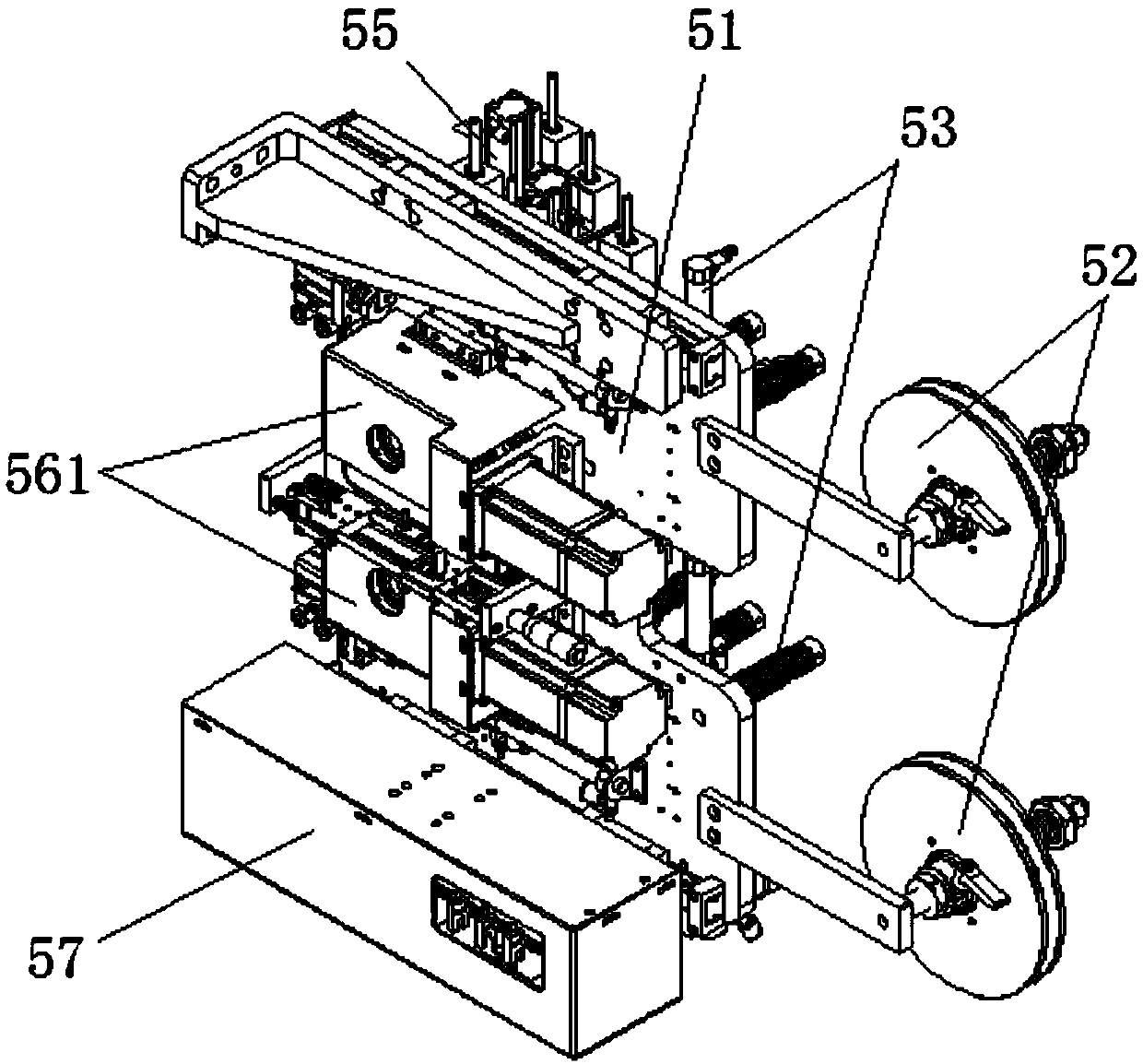

[0136] Such as figure 1 As shown, a cell manufacturing and winding integrated machine of the present invention includes a body and a positive electrode sheet processing part, a negative electrode sheet processing part, two sets of diaphragm processing parts, a winding part, a feeding manipulator 12, The ironing mechanism 13 and the cell conveying mechanism 14, the positive electrode sheet processing part includes the electrode sheet unwinding mechanism 1, the tab welding mechanism 2, the two tab protective glue mechanisms 5, the tension control device 7 and the sheet feeding mechanism arranged in sequence. Cutting mechanism 9; the negative plate processing part includes a pole piece unwinding mechanism 1, a tab welding mechanism 2, a tab protective glue mechanism 5, a tab welding mechanism 2, a tab protective glue mechanism 5, and a tension The control device 7 and the sheet feeding and cutting mechanism 9; the diaphragm processing part includes a diaphragm unwinding mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com