Epoxy resin insulating cap

A technology of epoxy resin and insulating caps, which is applied in the direction of guards/shutters to prevent contact with contacts, can solve the problems of aggravating the corrosion of conductive parts, shortening the service life of high-voltage switchgear, and easily generating short circuits in circuits, etc., to achieve excellent mechanics Performance, prevention of short circuit between phases or external discharge, prevention of oxidation and corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

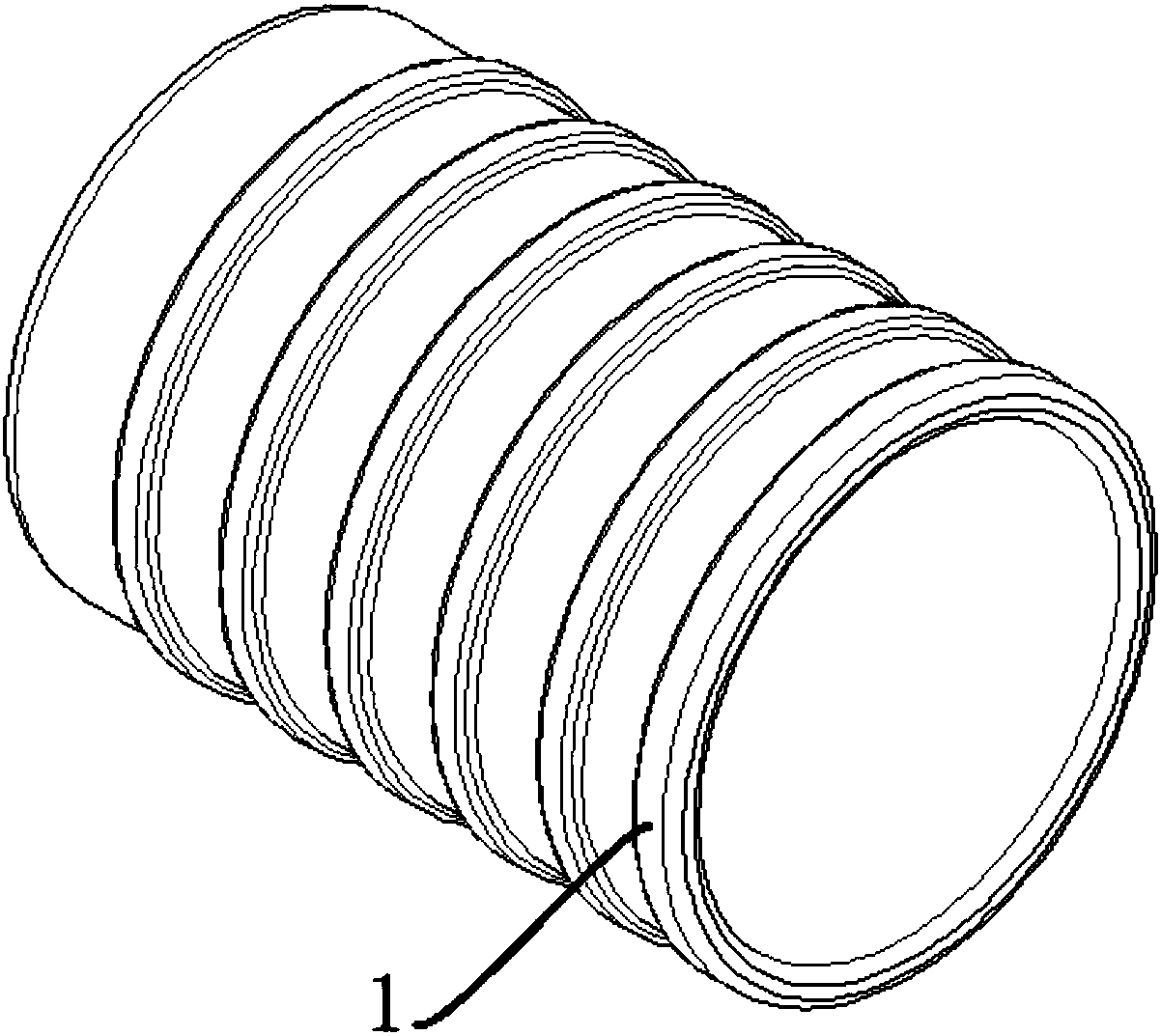

[0020] Such as figure 1 As shown, the present invention is an epoxy resin insulating cap, and the insulating cap is a hollow cylinder with one end open. When the insulating cap blocks the main circuit of the high-voltage switchgear, it often blocks the connection part of the main circuit of the high-voltage switchgear. The connection part of the main circuit of the high-voltage switchgear is provided with a mounting hole for installing the insulating cap. Fitted into the mounting hole of the main circuit of the high-voltage switchgear, the insulating cap isolates the conductive parts of the main circuit from the outside world, improving the insulation of the high-voltage switchgear to the outside world.

[0021] In a preferred embodiment, the outer cylindrical surface of the open end of the insulating cap is provided with an annular boss 1 . When the insulating cap is matched with the sealing ring of the insulating cap, the insulating cap is completely inserted into the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com