Dried bean curd and preparation process thereof

A preparation process and a technology for dried tofu, applied in the field of dried tofu and its preparation technology, can solve the problems that marinade is difficult to enter into the dried tofu blank, and the taste of the dried tofu is inconsistent inside and outside, and achieves the effects of improving yield and increasing uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: a kind of dried tofu, which is prepared through the following steps:

[0063] S1, feeding and soaking: Soak the soybeans in water for 15 hours according to the weight ratio of soybeans and water of 1:5, drain the water, and wash the soybeans;

[0064] S2, refining: refining the soaked soybeans in S1 to obtain a paste without grains;

[0065] S3, centrifugation: centrifuge the ground paste obtained in S2, remove the slag for the first time, and obtain raw soybean milk;

[0066] S4, continuous burning and sieving: the raw soybean milk obtained in S3 is subjected to eight continuous burning treatments, and the temperatures of the eight continuous burning treatments are 45°C, 55°C, 65°C, 75°C, 85°C, and 95°C respectively. °C, 105 °C, 110 °C, obtain cooked soybean milk with a concentration of 10%, filter it through a 120-mesh sieve, and remove the residue for the second time;

[0067] S5, pulping: fully mix the pulping mixture with water to obtain a pulping m...

Embodiment 2

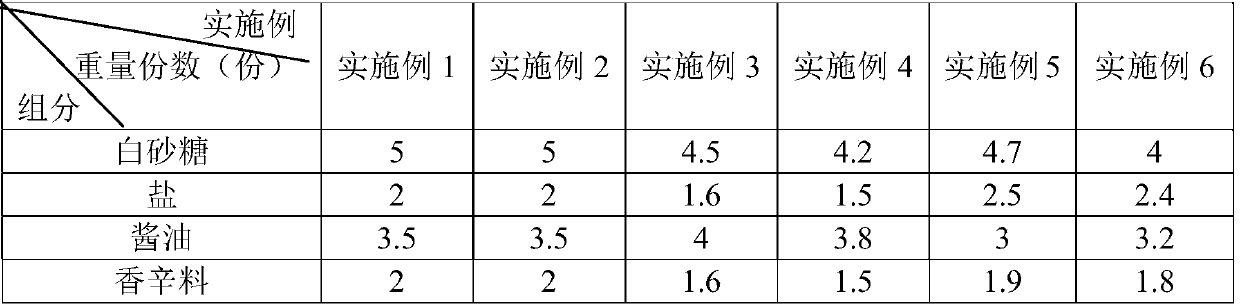

[0075] Embodiment 2: A kind of dried tofu, the difference from Embodiment 1 is that in S11, drying treatment is also included before the second cooling, the temperature of drying treatment is 40°C, and the time elapsed in drying treatment is 25 minutes; the second cooling is carried out at a temperature of 18° C., and the duration of the second cooling is 20 minutes. Wherein, the parts by weight of seasonings are as shown in Table 1.

Embodiment 3-6

[0076] Embodiment 3-6: a kind of dried tofu, the difference from embodiment 1 is that the parts by weight of the seasoning are as shown in Table 1.

[0077] Components and corresponding parts by weight of the seasoning in Table 1 embodiment 1-6

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com