Ultrasonic/microwave water heating/meto-super-critical reaction kettle

A microwave hydrothermal and supercritical technology, applied in chemical/physical/physicochemical processes, energy-applied chemical/physical/physicochemical processes, control/regulation processes, etc., can solve problems such as high energy consumption and single function, Achieve the effect of small size, strong penetrating ability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

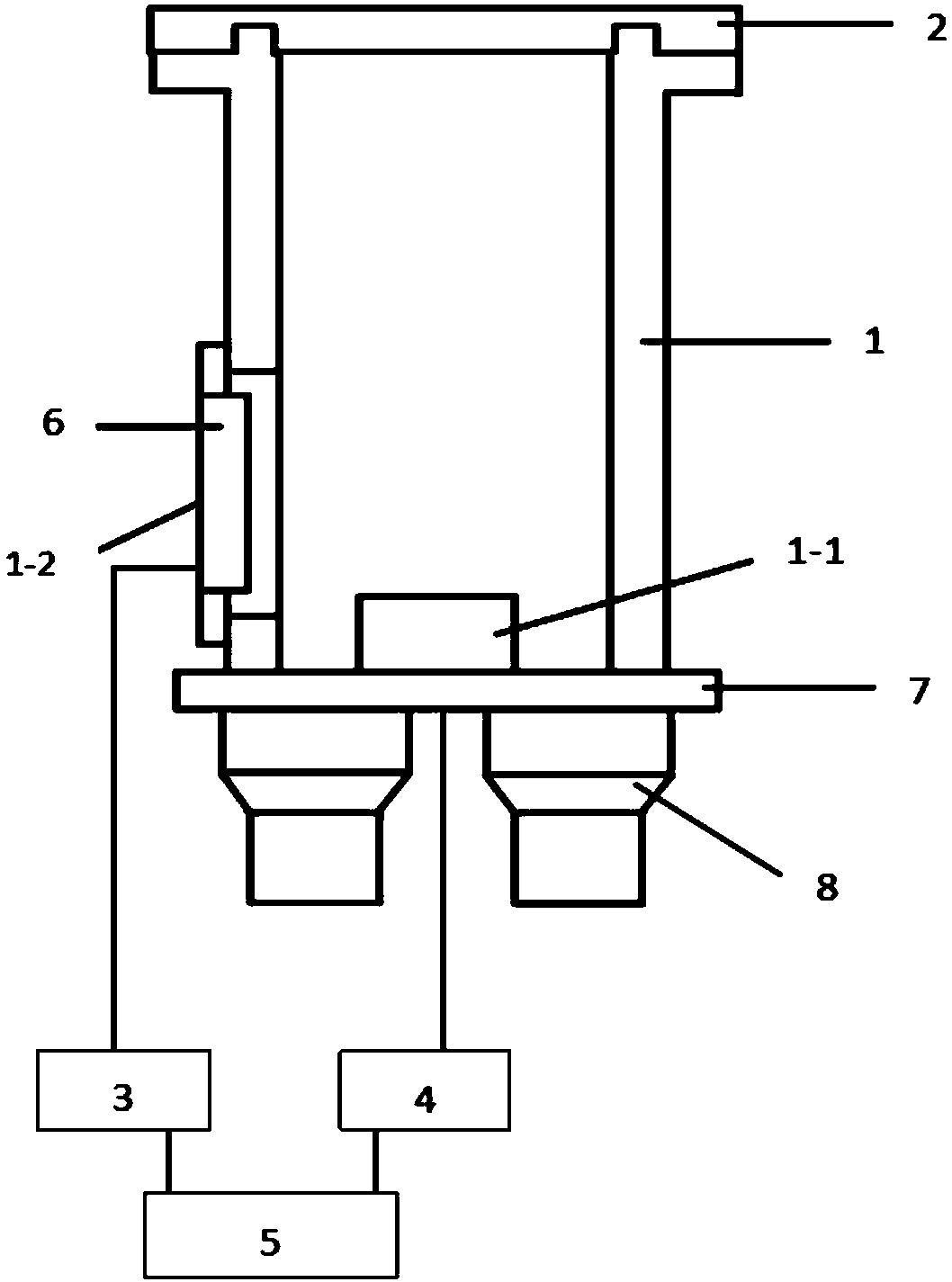

[0015] An ultrasonic / microwave hydrothermal / subsupercritical reaction kettle of the present invention comprises a kettle body 1, a kettle cover 2, an ultrasonic generator 4, a microwave generator 3, a controller 5, a microwave heating waveguide, and a vibrator 8;

[0016] The kettle cover 2 is located at the top of the kettle body 1, and covers the opening of the kettle body 1; the kettle body 1 is provided with a first interface 1-1 for connecting the vibrator 8; the vibrator 8 is at least one, each It is connected with the ultrasonic generator 4 to vibrate and heat the liquid in the kettle body 1 through ultrasonic waves; the bottom side wall of the kettle body 1 is provided with a second interface 1-2, and the microwave heating waveguide is arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com