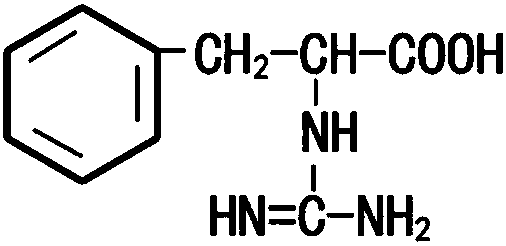

Preparation method of 2-guanidino phenylpropionic acid

A technology of guanidinophenylpropionic acid and phenylalanine, which is applied in the field of preparation of 2-guanidinophenylpropionic acid, can solve problems such as no synthetic method, and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

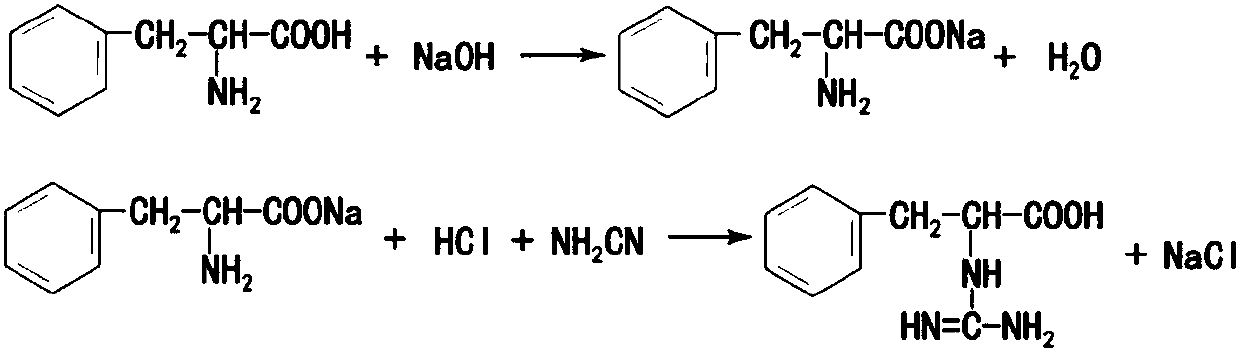

Method used

Image

Examples

Embodiment 1

[0018] Put 100Kg of phenylalanine and 200Kg of purified water into the reactor and mix them well, then adjust the pH value of the system to 8 with liquid caustic soda, then slowly raise the temperature of the reactor to 60°C and start adding 84.83Kg of 30% cyanamide dropwise For aqueous solution, control the dropping rate to 100L / h. After the addition of cyanamide is completed, keep the temperature at T=80°C for 2 hours, lower the temperature of the system to below 20°C and adjust the pH of the system to 8 with hydrochloric acid, and then start centrifugation. The solid was rinsed with ethanol, and the dried target product was 106Kg, the total yield was 84.5%, and the detection purity was 99.3%.

Embodiment 2

[0020] Put 100Kg of phenylalanine and 200Kg of purified water into the reactor and mix them well, then adjust the pH value of the system to 9 with liquid caustic soda, then slowly raise the temperature of the reactor to 70°C and start adding 84.83Kg of 30% cyanamide dropwise For aqueous solution, control the dropping rate to 120L / h. After the addition of cyanamide is completed, keep the temperature at T=80°C for 2 hours, lower the temperature of the system to below 20°C and adjust the pH of the system to 7 with hydrochloric acid, and then start centrifugation. The solid was rinsed with ethanol, and 110Kg of the target product was dried, with a total yield of 87.7% and a detection purity of 99.2%.

Embodiment 3

[0022] Put 100Kg of phenylalanine and 200Kg of mother liquor into the reaction kettle and mix them thoroughly, then adjust the pH value of the system to 9 with liquid caustic soda, then slowly raise the temperature of the reaction kettle to 70°C and start adding 101.80Kg of 30% cyanamide aqueous solution dropwise , control the dropping rate to 120L / h, after the addition of cyanamide, keep the temperature at T=80°C for 2h, lower the temperature of the system to below 20°C, adjust the pH of the system to 7 with hydrochloric acid, then start centrifugation, after centrifugation The solid was rinsed with ethanol, and 115Kg of the target product was dried, with a total yield of 91.7% and a detection purity of 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com