Mold bag concrete slope protecting structure and rebar cage with anchoring structure

A technology for moulded bagged concrete and anchoring structure, which is applied in basic structure engineering, coastline protection, marine engineering and other directions, can solve the problems of moulded bagged concrete damage, top damage, lack of The effect of force and slope densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

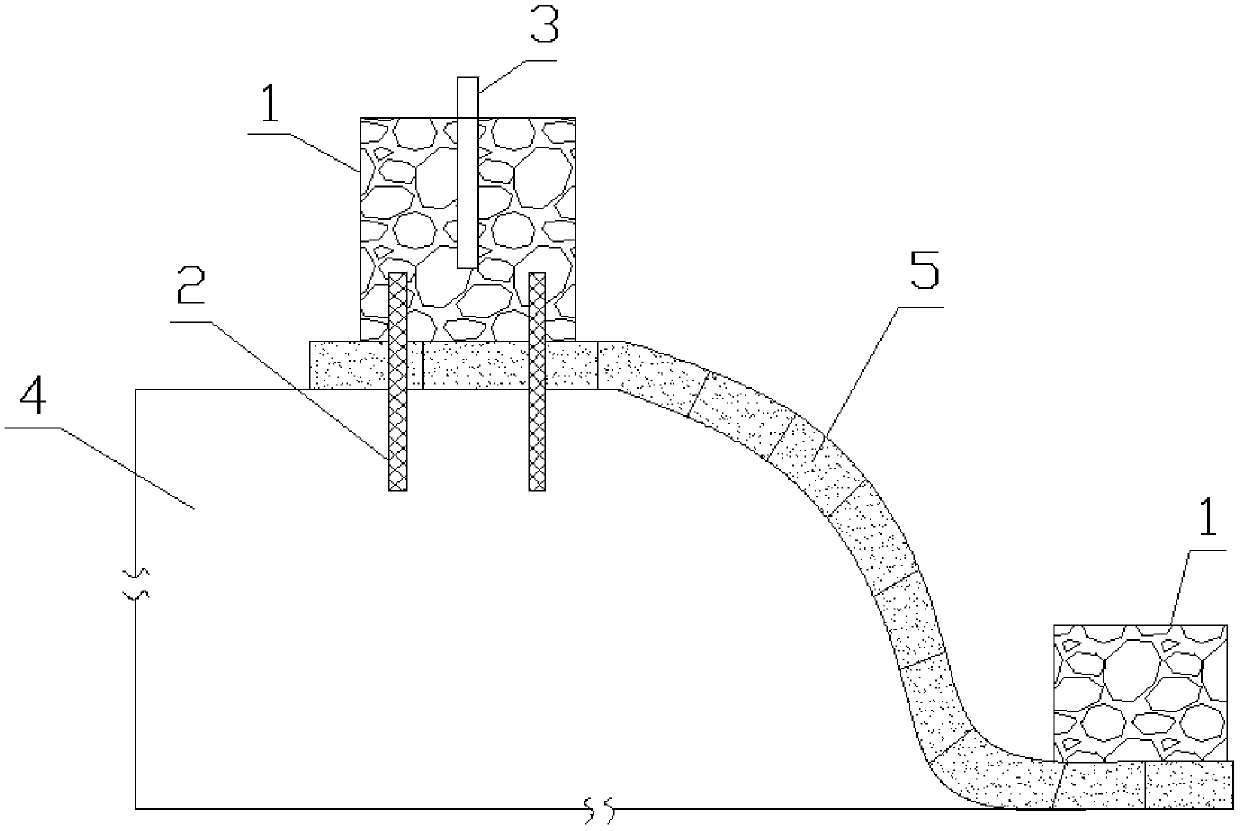

[0030] The construction steps of the mold bag concrete slope protection structure are as follows:

[0031] (1) First of all, the mold bag concrete is placed on the slope, with a distance of about 1.2m from the top of the slope, and about 0.5m from the bottom of the slope to the valley;

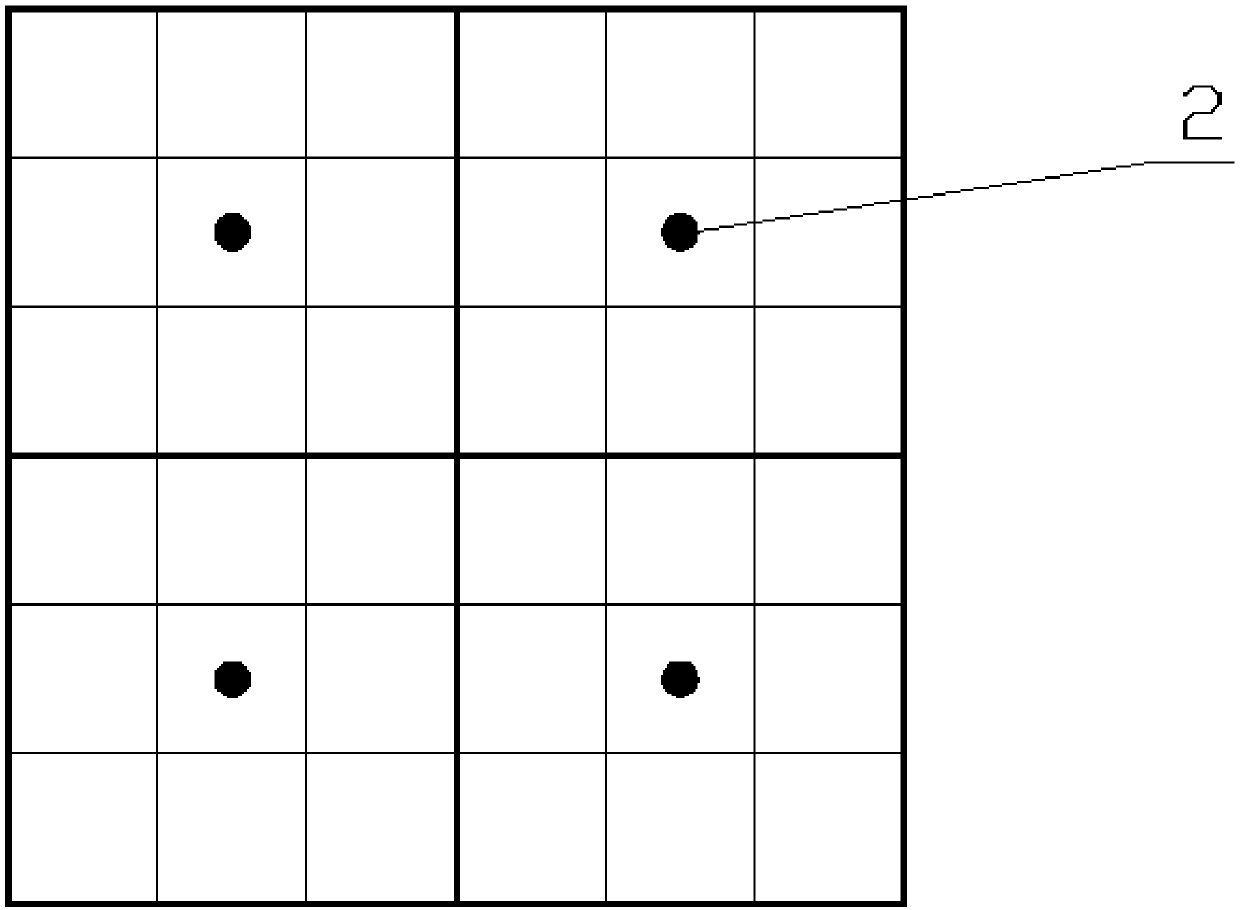

[0032] (2) After the mold bag concrete is filled with concrete, put the reinforcement cage on the upper part of the mold bag concrete, and then insert an appropriate length of anchoring steel bar as an anchor rod, and anchor to the road surface at least 0.5m above;

[0033](3) Put rocks of a certain particle size into the reinforcement cage and put them into the grouting pipe at the same time;

[0034] (4) Use the reinforced gabion template made in advance, and use the same concrete as the bagged concrete to grout the inside of the reinforced gabion through the grouting pipe, so that the internal blocks and the bagged concrete form a whole, and further anchor the bagged concrete slope protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com