Penetration shearing device and method for foundation in-situ testing based on optical fiber and optical grating

A fiber grating, in-situ testing technology, used in measuring devices, using a stable shear force to test the strength of materials, instruments, etc., can solve the problems of limited application, short-circuiting of strain gauges, large artificial errors, etc., and achieve anti-electromagnetic interference. Strong ability, reduced disturbance, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

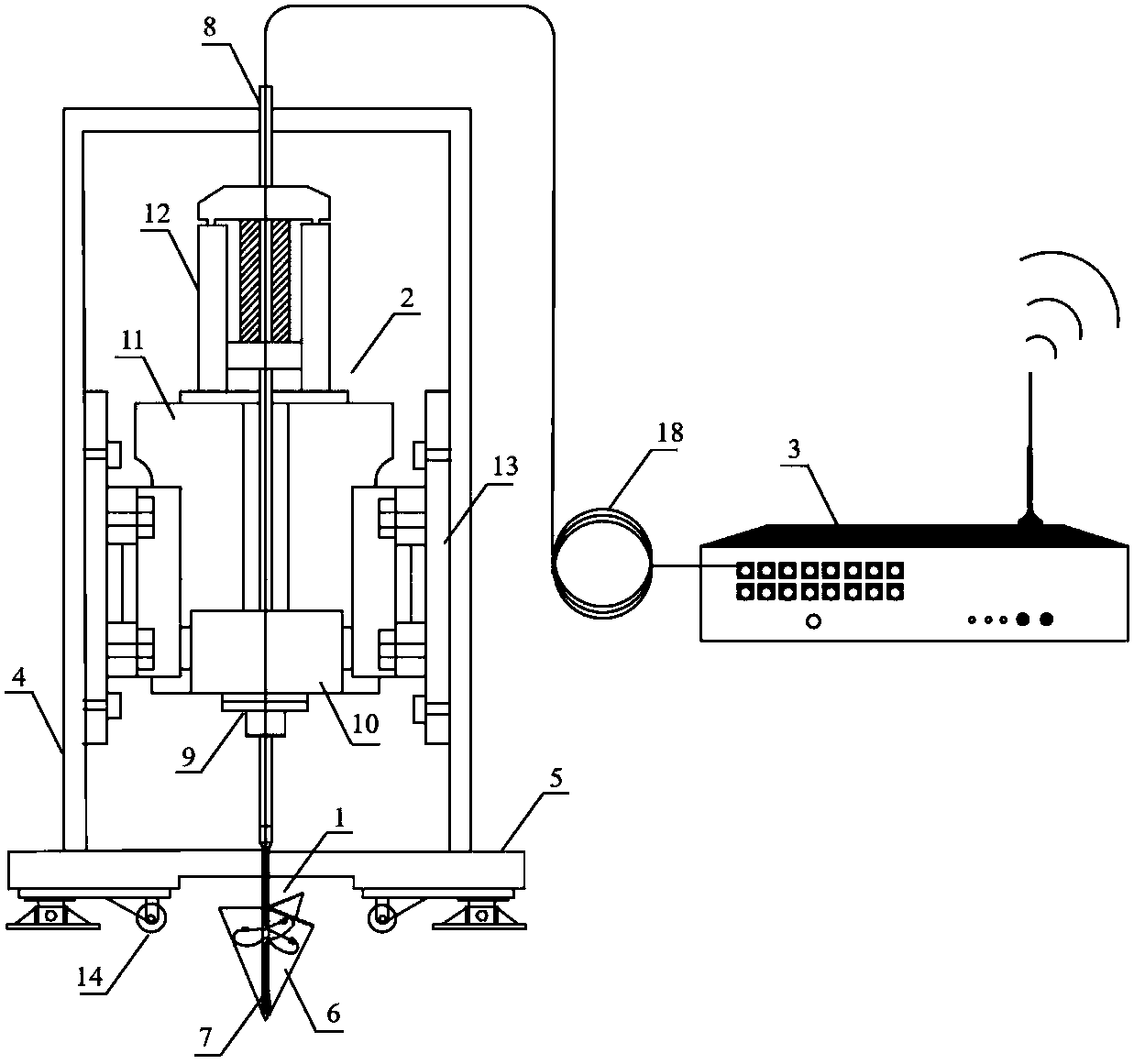

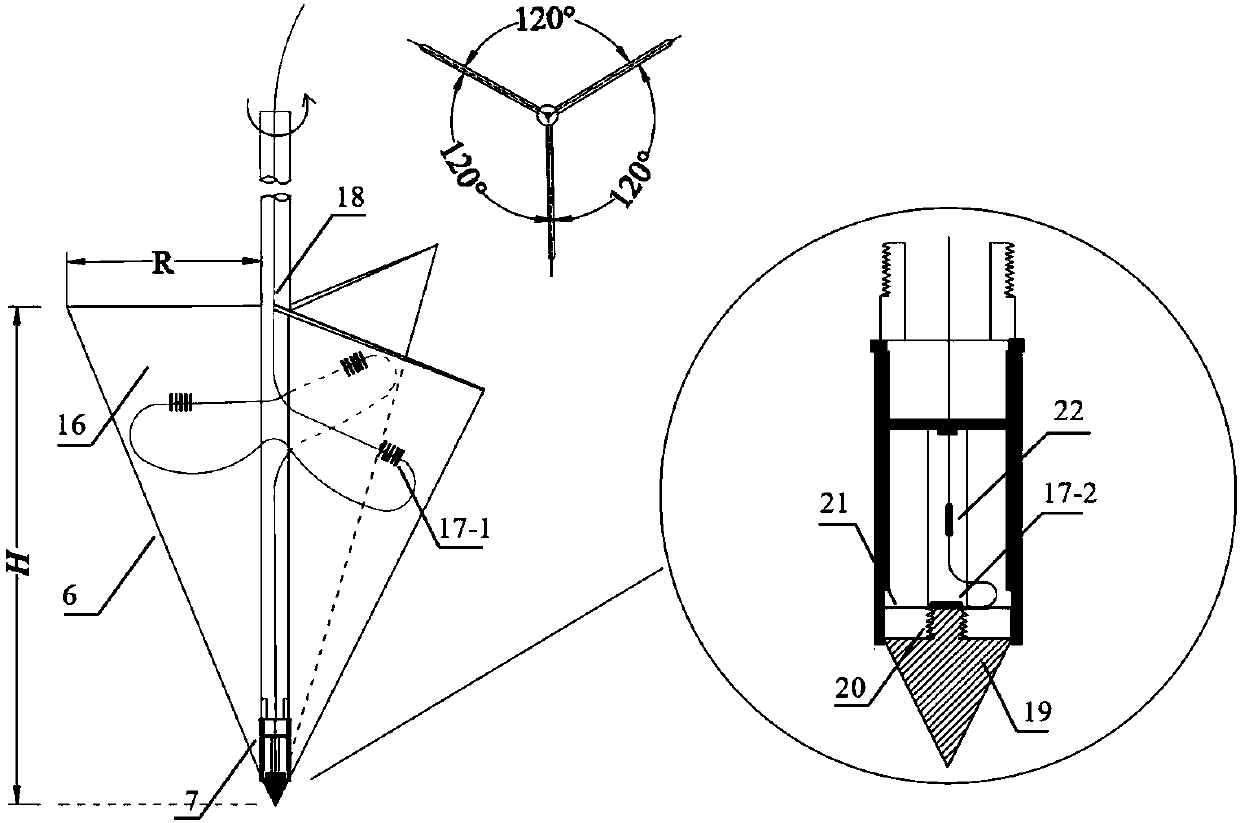

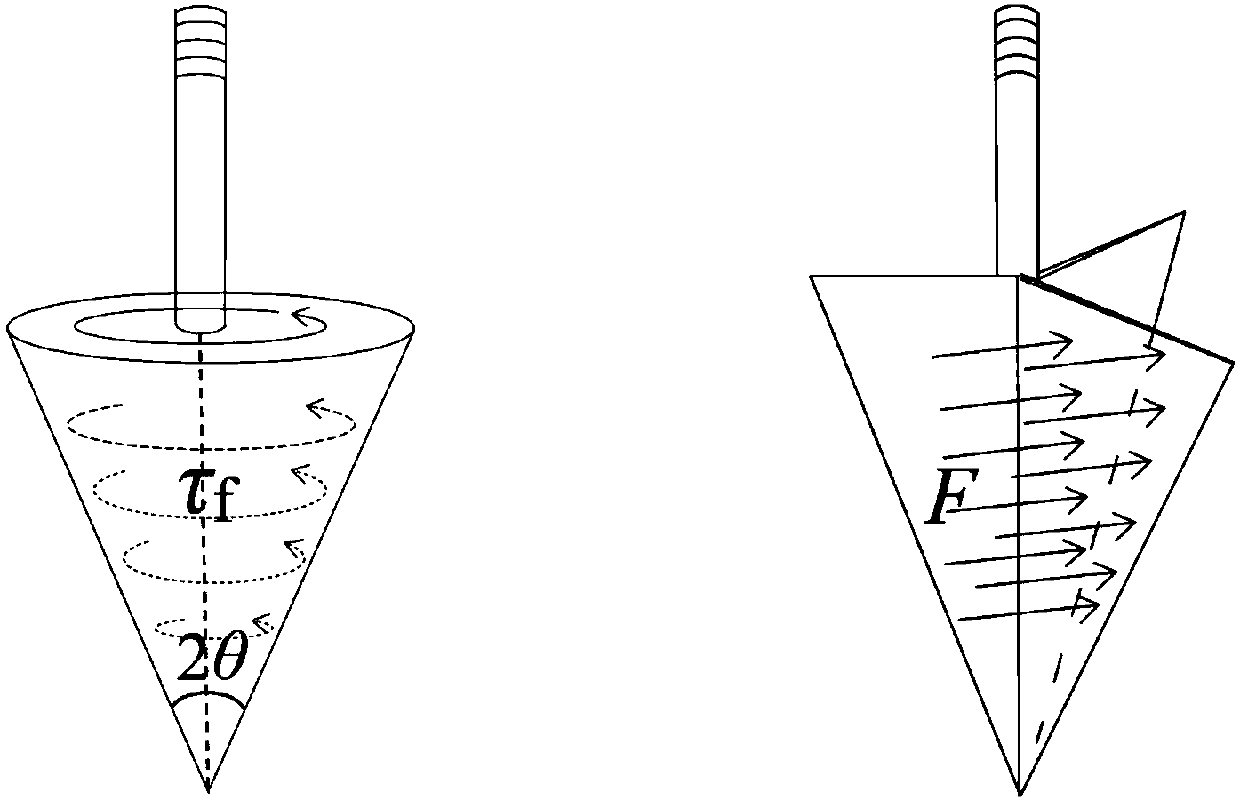

[0053] as attached figure 1 And attached figure 2 As shown, a penetration shearing device based on fiber gratings for foundation in-situ testing includes a multi-function probe 1 , a rotary drilling device 2 , a fiber grating wireless demodulator 3 , a chassis shell 4 and a base 5 . The multifunctional probe 1 includes a Y-shaped plate head 6 and a cone-point probe 7, and the cone-point probe 7 is installed at the bottom of the Y-shaped plate head 6; the rotary drilling device 2 includes a probe rod 8, Chuck 9, stepper motor 10, installation platform 11, press-in host 12, and fixing device 13; the probe rod 8 runs through the entire rotary drilling device 2 from bottom to top, and passes through the chuck 9, step The motor 10, the installation platform 11 and the press-in host 12 are connected to the bottom of the multi-function probe 1; the rotary drilling device 2 is installed on the inner wall of the chassis shell 4 through the fixing device 13; the chassis shell 4 is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com