Design and manufacturing method of novel lightweight propeller

A manufacturing method and propeller technology, applied in calculation, instrumentation, geometric CAD, etc., can solve problems such as excessive vibration and noise energy consumption, achieve the effects of reducing weight, improving surface hydrodynamic performance, and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

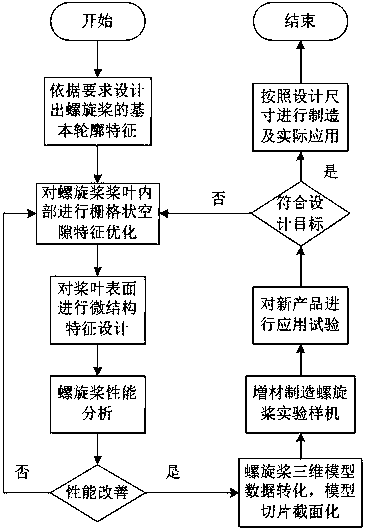

[0023] The design and manufacturing method of the new lightweight propeller in this embodiment, the basic contour features of the propeller are designed according to the requirements, and then the interior of the propeller blade is topologically optimized to obtain a grid-like void structure. Surface microstructure treatment is carried out to optimize the curved surface characteristics of the current blade; after the design is completed, the new lightweight propeller is integrated with the internal grid and surface microstructure of the propeller through additive manufacturing technology; among them, the specific process of design and manufacturing, like figure 1 As shown, the design process includes the following steps:

[0024] (1) Initial design: Complete the preliminary design of the basic structure of the propeller according to the load and horsepower performance requirements, obtain a propeller with a specific diameter, pitch, pitch angle and disk-to-surface ratio, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com