A speed sensorless control method suitable for high torque start of asynchronous motor

A speed sensorless, asynchronous motor technology, used in motor generator control, electronic commutation motor control, control systems, etc., can solve problems such as large amount of calculation, reduced reliability, and increased system cost, and achieves fast response speed, Reduce the effect of chattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings.

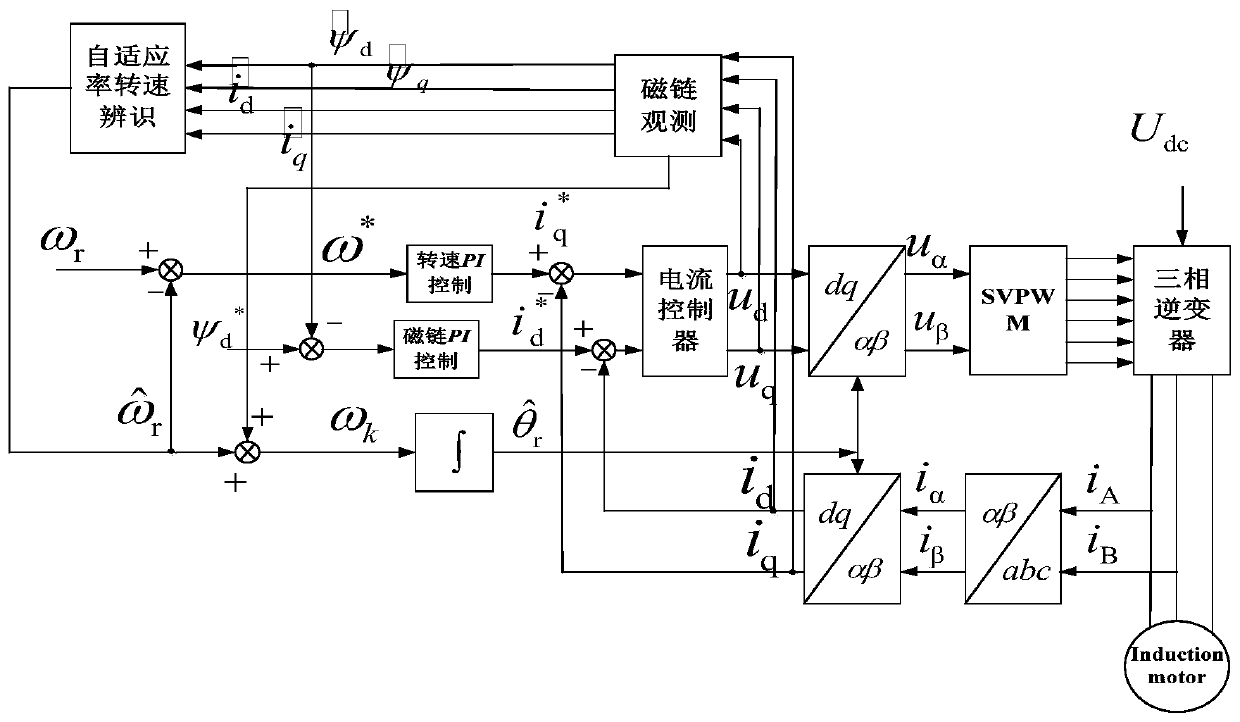

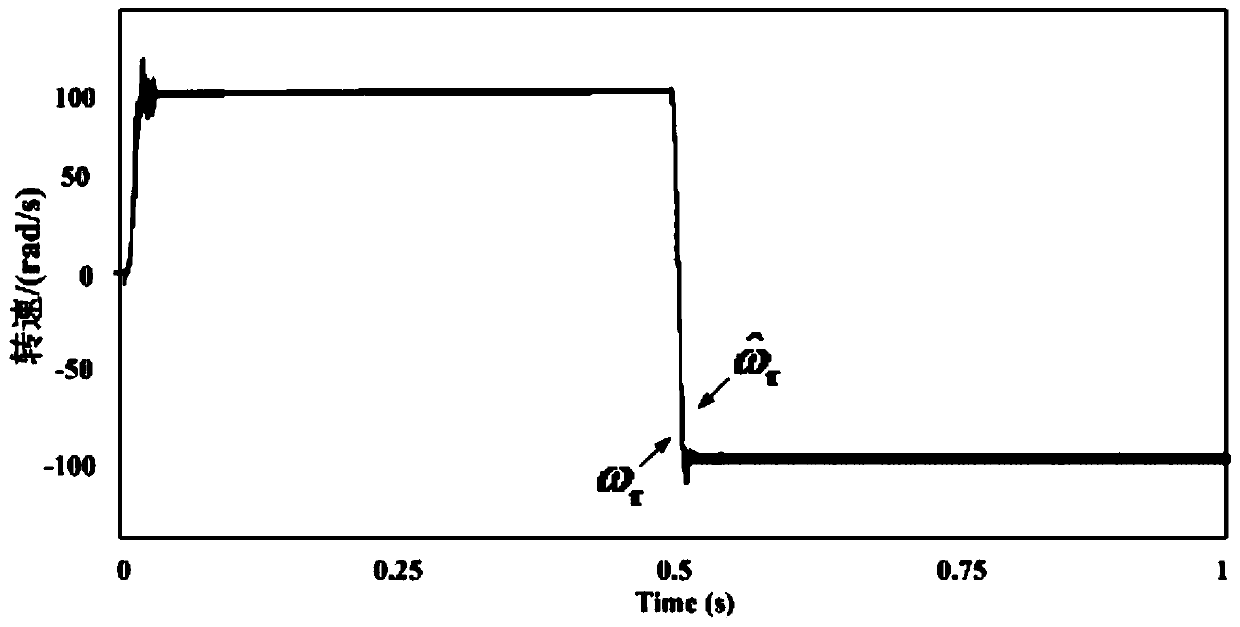

[0044] refer to figure 1 , based on the rotating coordinate method, combined with the model motor method, the adaptive law of the estimated rotational speed is obtained through the Lyapunov nonlinear design method, and the sliding mode control method is used to control the model motor current, accurately locate the rotor position angle, and make the model motor current The error between the current and the actual motor current is zero, which can efficiently realize high-torque starting.

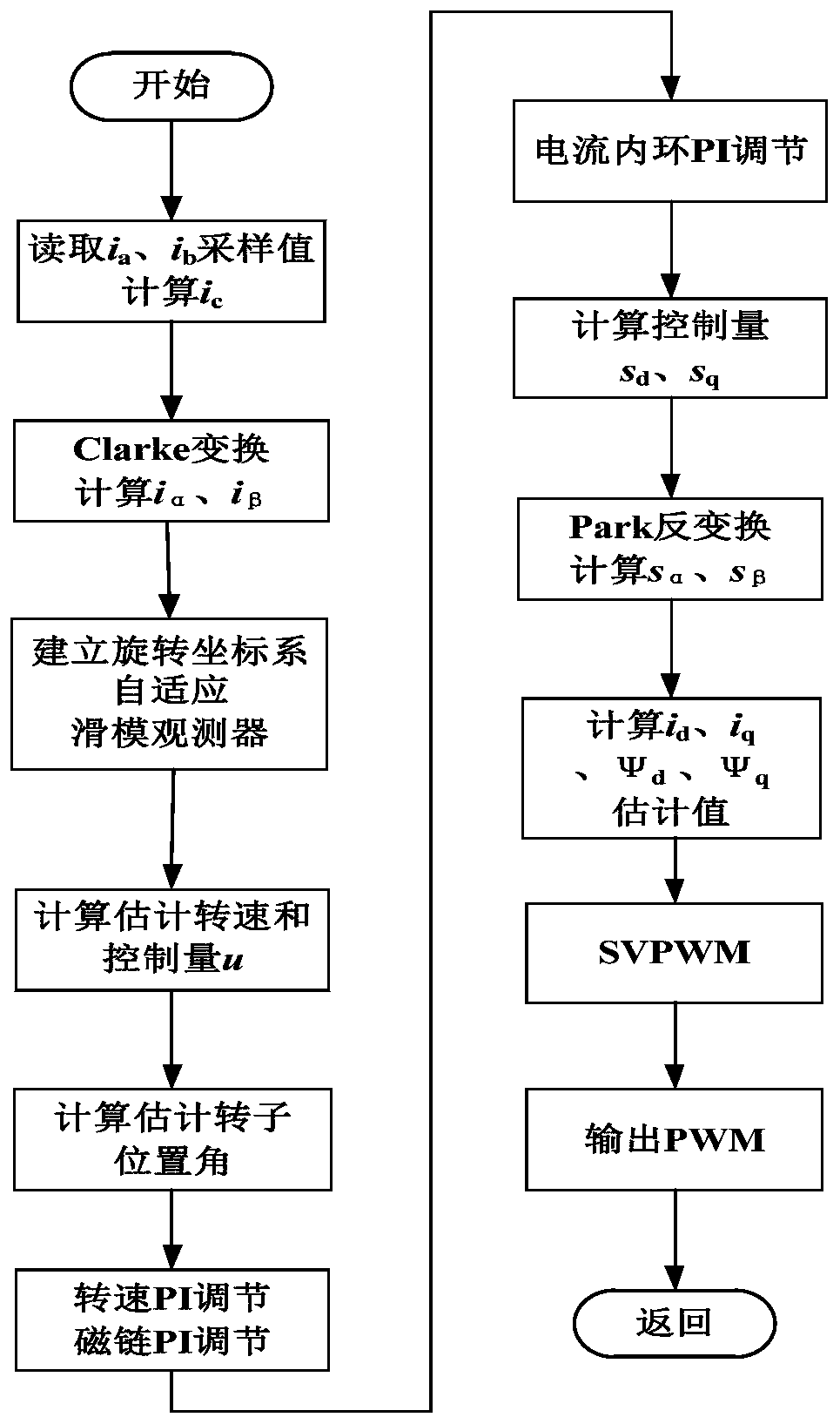

[0045] refer to figure 1 and figure 2 As shown in the flow chart of the present invention, a speed sensorless control method suitable for high-torque starting of asynchronous motors of the present invention includes:

[0046] 1. Acquisition of motor stator A-phase current i A , B-phase current i B and inverter DC bus voltage U dc , and calculate the corresponding C-phase curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com