Flue purification system for precision casting roasting furnace

A flue gas purification and kiln technology, applied in the direction of furnaces, furnace components, chemical instruments and methods, etc., can solve problems such as insufficient wax combustion, and achieve the effect of improving the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

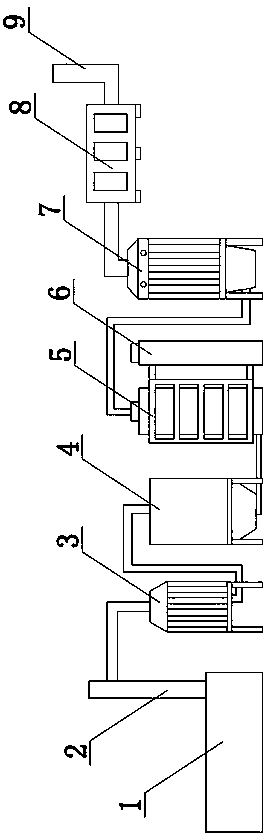

[0018] Example: such as figure 1 As shown, a precision casting roasting furnace flue purification system includes a furnace 1, the exhaust pipe 2 of the furnace 1 is connected to a cooling tower 3, and the cooling tower 3 is connected to a bag type dust collector 4, and the bag type dust collector The device 4 is connected with a water film deduster 5 again, and the side of the water film deduster 5 is also connected with a chilled water unit 6. The water film dust collector 5 is connected with an electrostatic precipitator 7, and the electrostatic precipitator 7 is connected with a UV photolysis air cleaner 8, and the UV photolysis air cleaner 8 is finally connected with a high-altitude chimney 9.

[0019] Use: In the present invention, the waxy smoke in the kiln is first sent to the cooling tower for cooling. Then use the bag filter to filter out the large and specific dust in the smoke, and filter out the finer dust in the smoke. Followed by the water film dust collector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com