Single-cylinder cone crusher

A cone crusher and single-cylinder technology, applied in grain processing, etc., can solve problems such as poor working stability of cone crushers, overturning of the main shaft and bushing, troublesome assembly and maintenance, etc., to reduce the probability of bearing damage and improve the force environment, easy assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

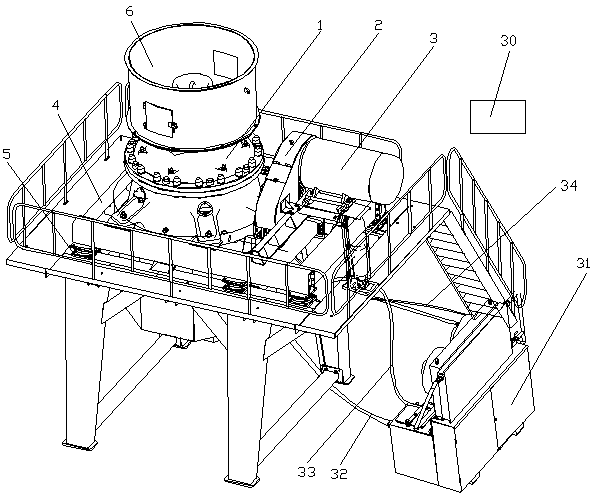

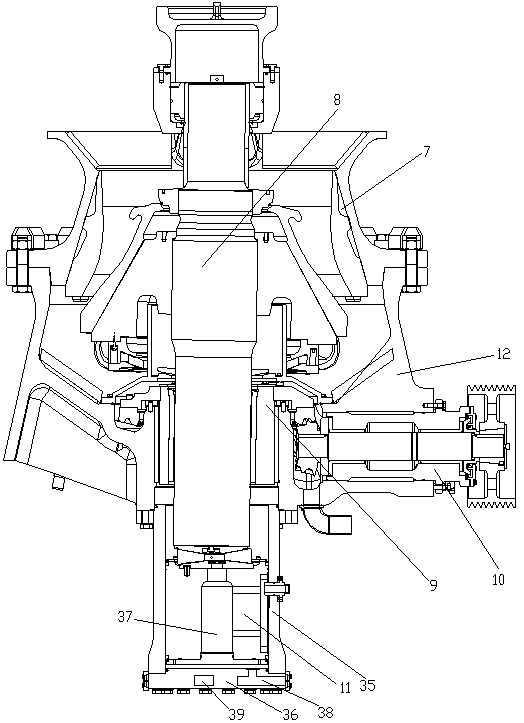

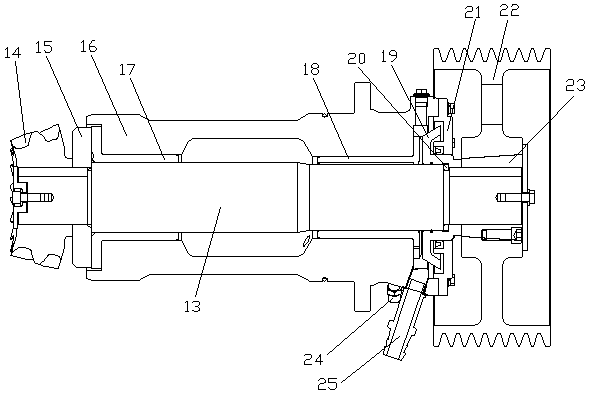

[0036] A single-cylinder cone crusher, comprising a main crushing machine 1, a transmission part 2, a driving part 3, a movable platform frame 4, a fixed platform frame 5 and a feeding hopper 6, the feeding hopper 6 is arranged on the main crushing machine 1, and the driving part 3. The transmission part 2 is connected with the crushing main frame 1, and the movable platform frame 4 is installed on the fixed platform frame 5 through a shock pad. The crushing main frame 1 includes an upper frame 7, a main shaft assembly 8, an eccentric assembly 9, a horizontal shaft The assembly 10, the piston assembly 11 and the lower frame 12 connected with the upper frame 7, the main shaft assembly 8, the eccentric assembly 9, the horizontal shaft assembly 10 and the piston assembly 11 are installed on the lower frame 12, The horizontal shaft assembly 10 is connected with the eccentric assembly 9, the upper frame 7 and the main shaft assembly 8 are positioned through joint bearings, the main ...

Embodiment 2

[0039] A single-cylinder cone crusher, comprising a main crushing machine 1, a transmission part 2, a driving part 3, a movable platform frame 4, a fixed platform frame 5 and a feeding hopper 6, the feeding hopper 6 is arranged on the main crushing machine 1, and the driving part 3. The transmission part 2 is connected with the crushing main frame 1, and the movable platform frame 4 is installed on the fixed platform frame 5 through a shock pad. The crushing main frame 1 includes an upper frame 7, a main shaft assembly 8, an eccentric assembly 9, a horizontal shaft The assembly 10, the piston assembly 11 and the lower frame 12 connected with the upper frame 7, the main shaft assembly 8, the eccentric assembly 9, the horizontal shaft assembly 10 and the piston assembly 11 are installed on the lower frame 12, The horizontal shaft assembly 10 is connected with the eccentric assembly 9, the upper frame 7 and the main shaft assembly 8 are positioned through joint bearings, the main ...

Embodiment 3

[0043] A single-cylinder cone crusher, comprising a main crushing machine 1, a transmission part 2, a driving part 3, a movable platform frame 4, a fixed platform frame 5 and a feeding hopper 6, the feeding hopper 6 is arranged on the main crushing machine 1, and the driving part 3. The transmission part 2 is connected with the crushing main frame 1, and the movable platform frame 4 is installed on the fixed platform frame 5 through a shock pad. The crushing main frame 1 includes an upper frame 7, a main shaft assembly 8, an eccentric assembly 9, a horizontal shaft The assembly 10, the piston assembly 11 and the lower frame 12 connected with the upper frame 7, the main shaft assembly 8, the eccentric assembly 9, the horizontal shaft assembly 10 and the piston assembly 11 are installed on the lower frame 12, The horizontal shaft assembly 10 is connected with the eccentric assembly 9, the upper frame 7 and the main shaft assembly 8 are positioned through joint bearings, the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com