Method of preparing corrosion-resistant crystal lamp pendant

A crystal lamp, corrosion-resistant technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of easy wear, scratches, corrosion, influence, etc., to achieve good physical properties and corrosion resistance performance, anti-corrosion, anti-scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A method for preparing a corrosion-resistant crystal lamp pendant, comprising the following steps:

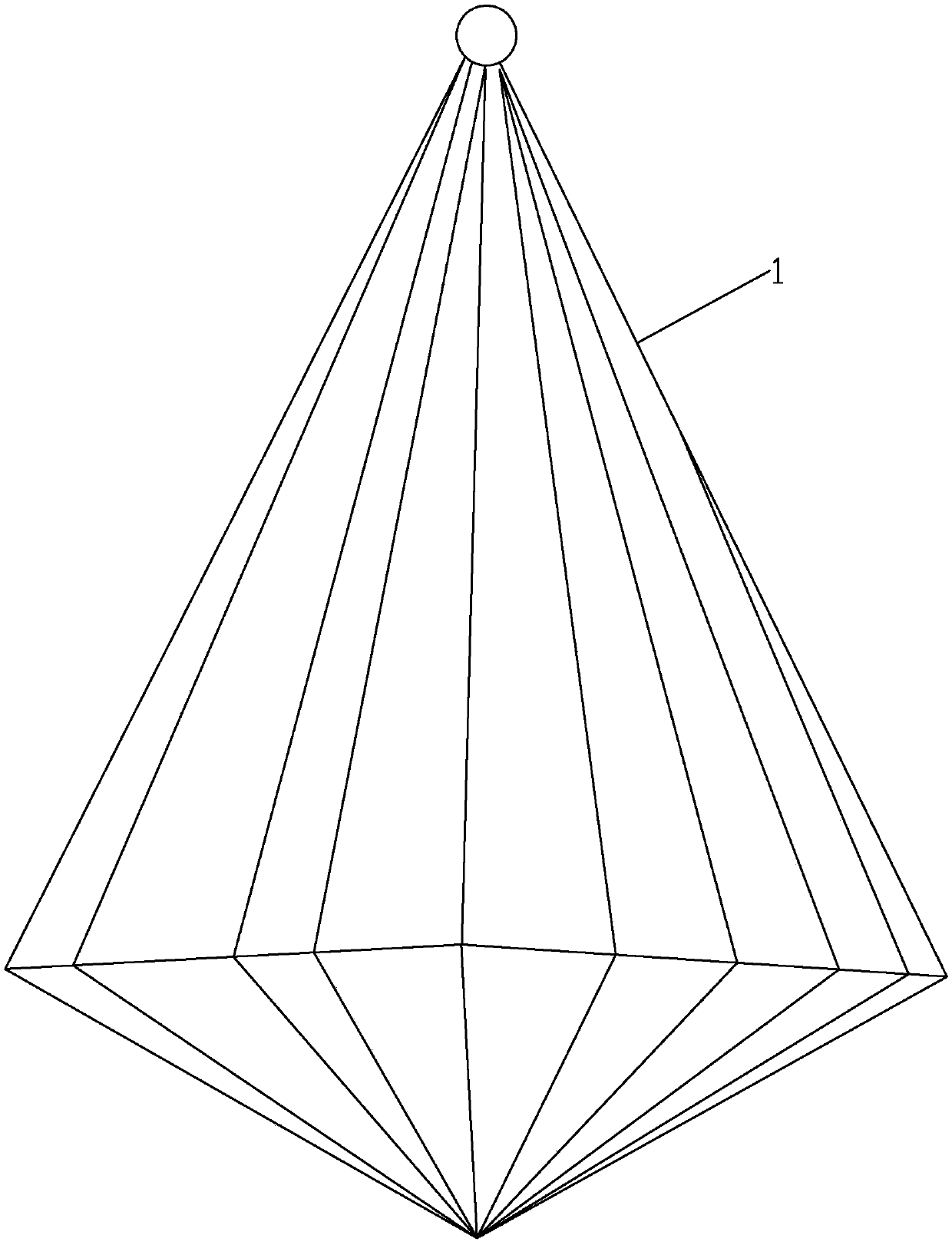

[0030] At first the first step, carry out the crystal lamp pendant 1 of cleaning molding, refer to figure 1 , the steps are: after ultrasonically cleaning the formed crystal lamp pendant in acetone for 10 minutes, then ultrasonically cleaning with ethanol for 10 minutes, and finally ultrasonically cleaning in deionized water for 10 minutes;

[0031] Then proceed to the second step, after cleaning the formed crystal lamp pendant 1, put it into the magnetron sputtering tray, and then send it into the coating machine;

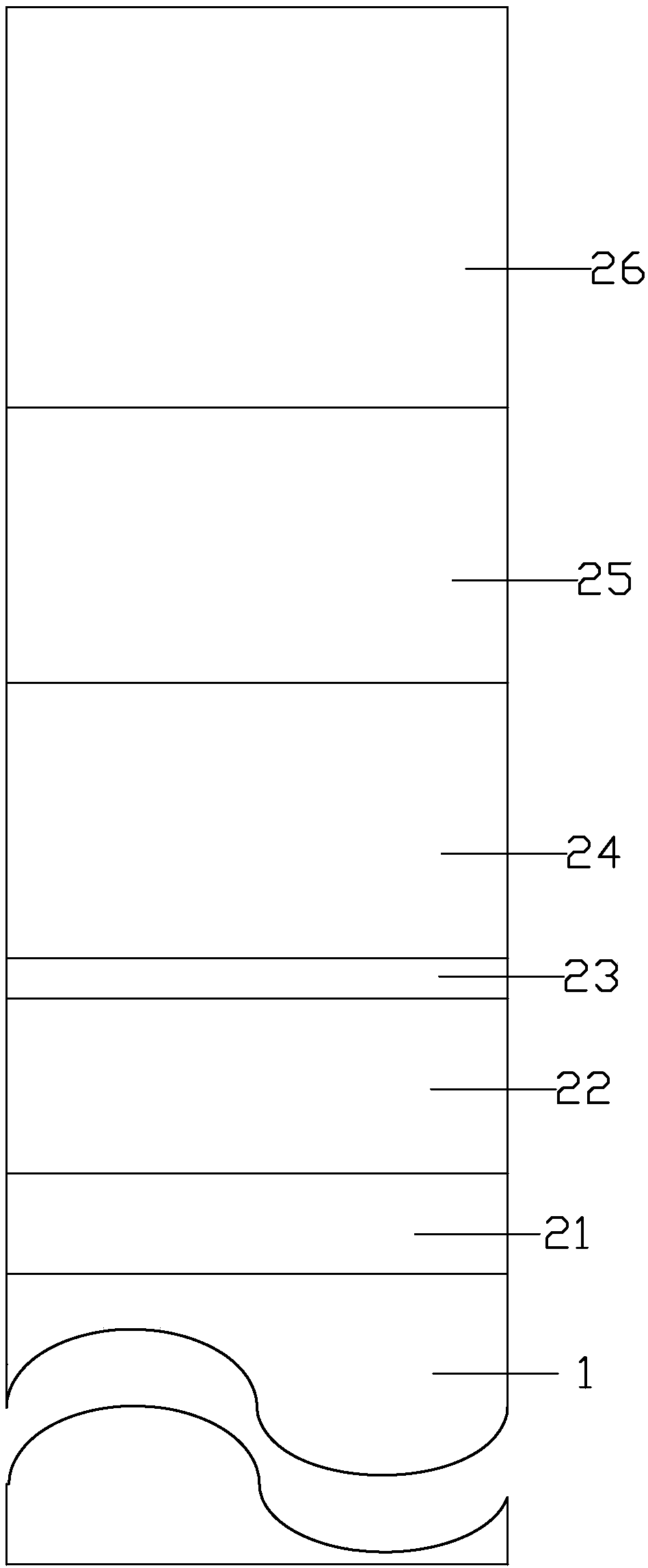

[0032] The last step, coating, such as figure 2 ,Methods as below:

[0033] (1) Magnetron sputtering B on the surface of the crystal lamp pendant 2 o 3 For layer 21, oxygen is used as the reaction gas, argon is used as the protective gas, and a bismuth planar target is sputtered with a DC power supply. The ratio of argon to oxygen is 300-500SCCM: 500-80...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap