An optimized road surface deicing machine

A technology of ice machines and ice blades, which is applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of waste of resources, large volume, and insufficient use of power devices, etc., and achieve the effect of compact structure and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

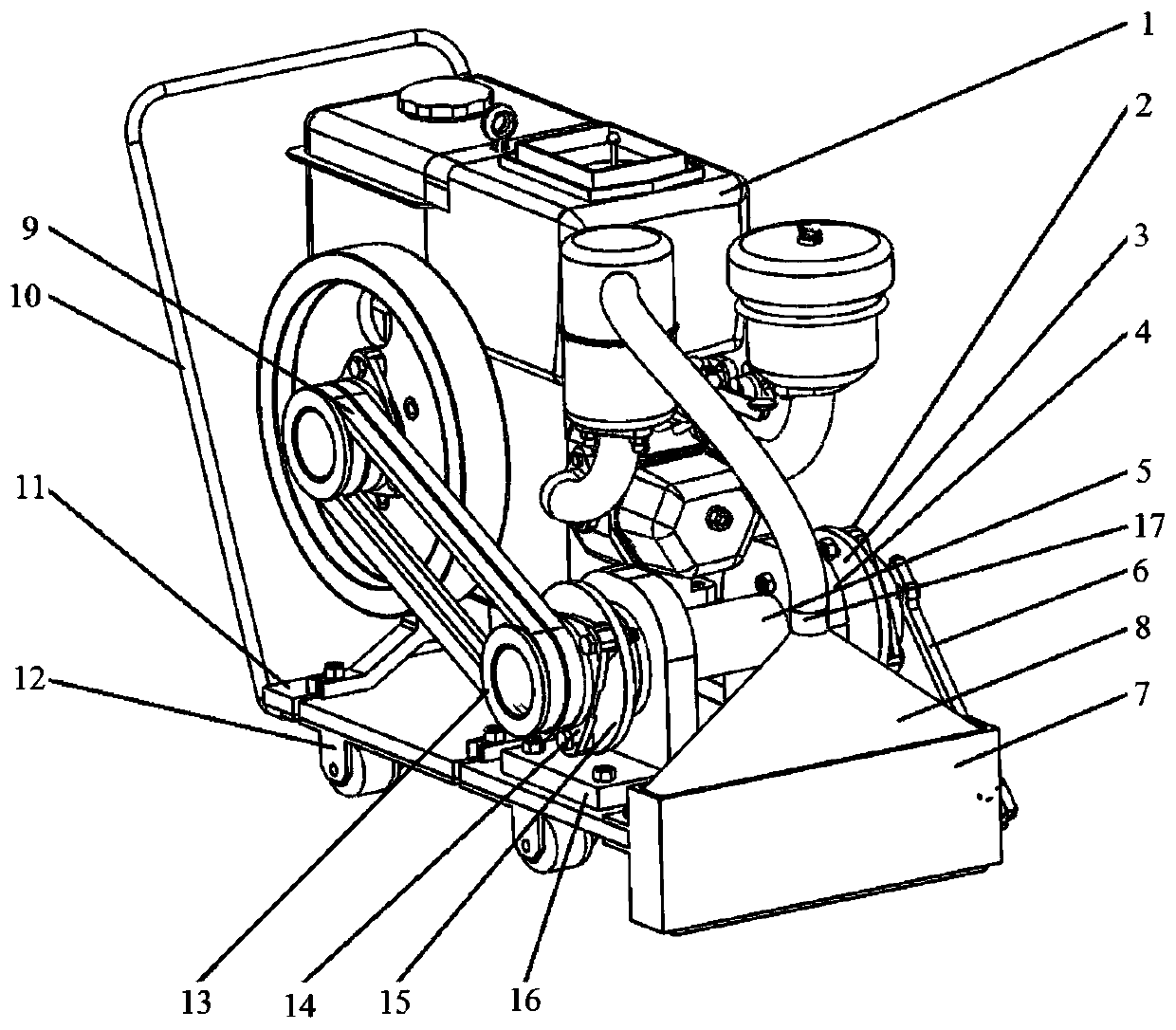

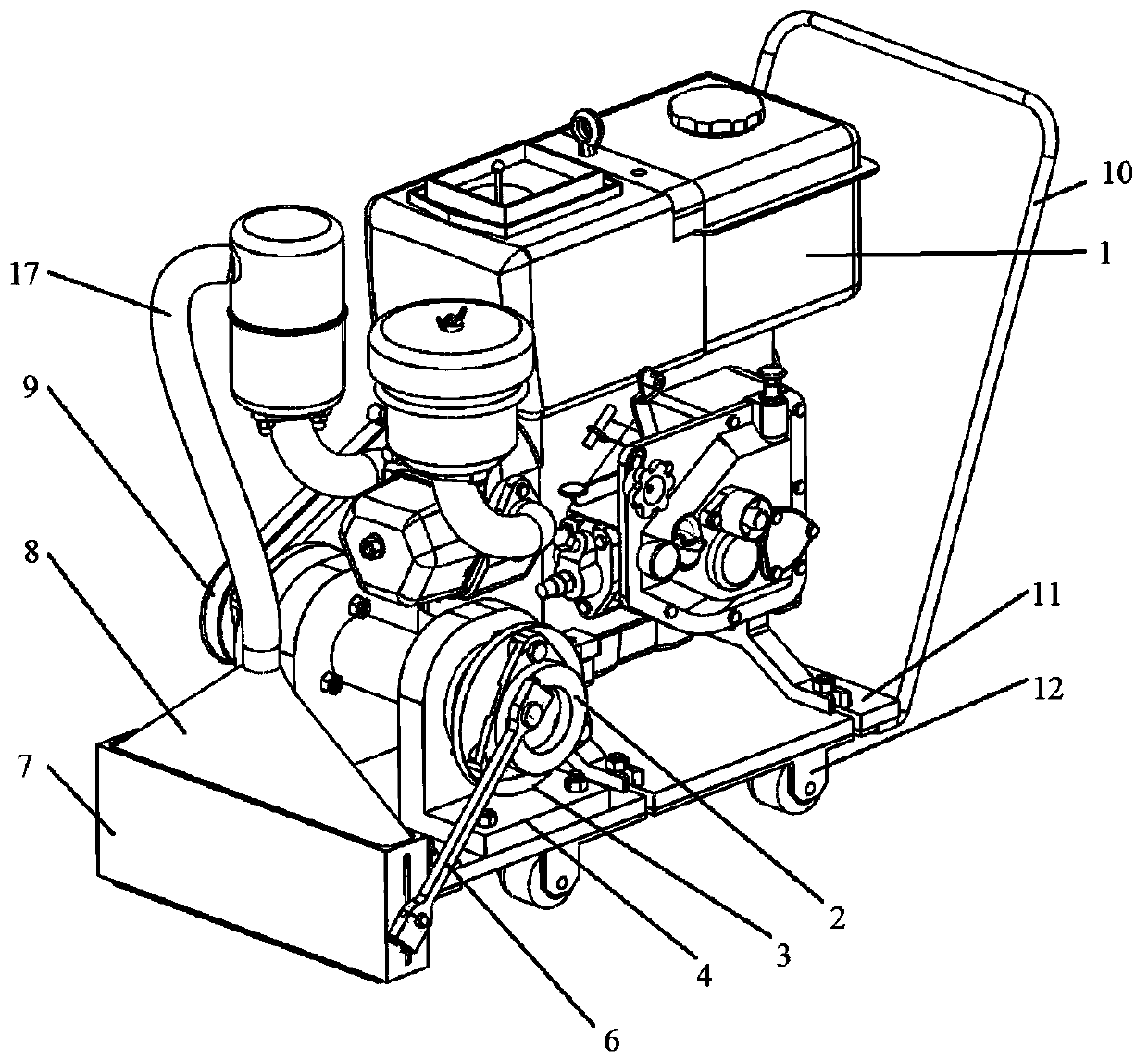

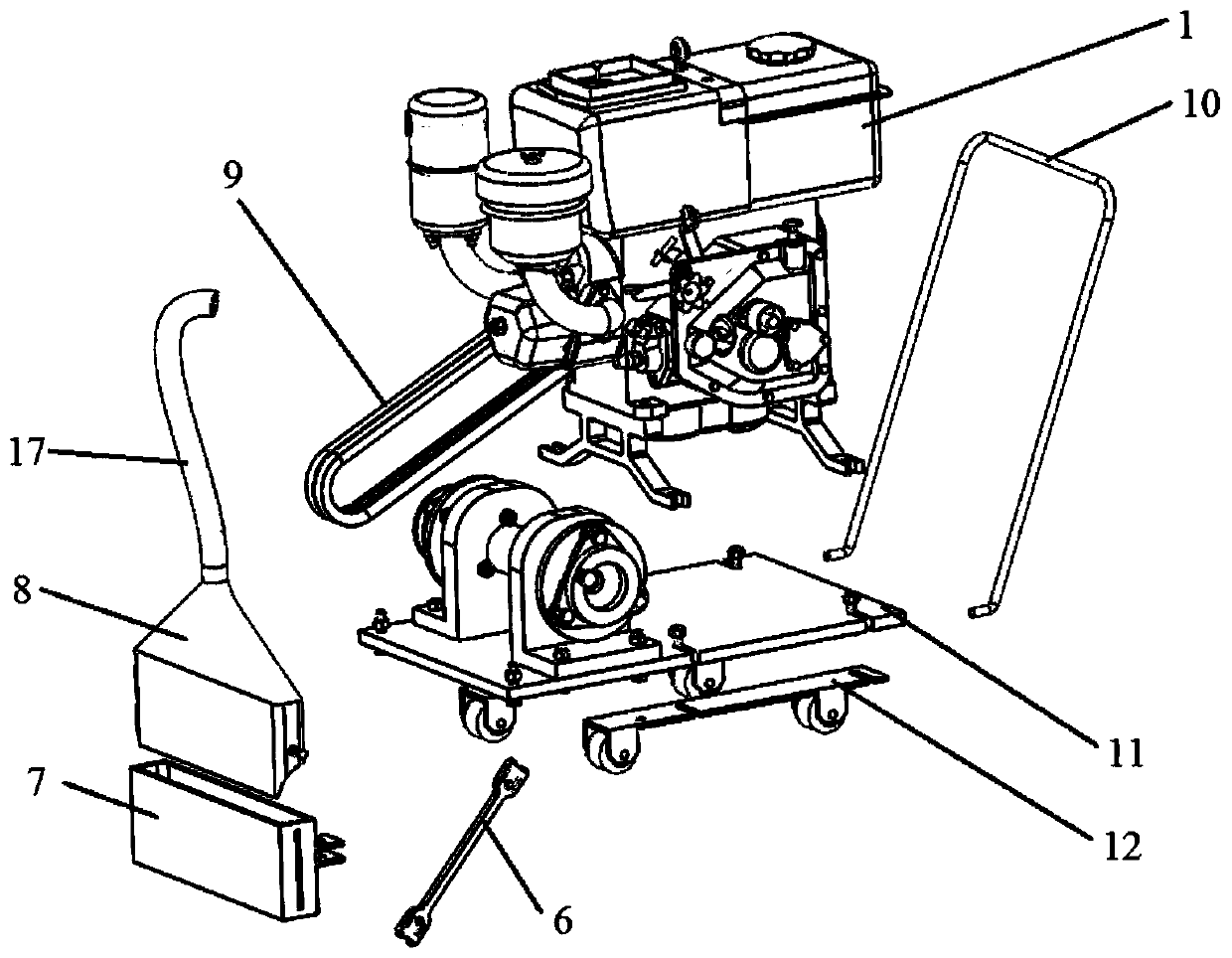

[0019] combine figure 1 , figure 2 and image 3 A specific structure of the present invention will be described. The present invention is mainly made up of five parts, diesel engine 1, base plate 11 and roller 12, handrail 10, transmission part and deicing part. The diesel engine 1 provides power for the deicing machine; the bottom plate 11 and the rollers 12 support the overall structure; the handrail 10 is convenient for use and transfer; the transmission part transmits the power from the diesel engine 1 to the deicing part; the deicing part reciprocates up and down for deicing . The ice blade is hollow inside, and the soft exhaust pipe connects the ice blade and the exhaust nozzle of the diesel engine. When working, the exhaust gas of the diesel engine and the skates work together on the ice. The diesel engine and the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com