Precise casting module and casting method for preparing nickel base single crystal guide blade with precisely controllable crystal orientation by using precise casting module

A module and precision casting technology, which is applied in the field of precision casting, can solve problems such as limiting the development of aero-engines, achieve good grain integrity, improve casting pass rate and quality, and have good crystal orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

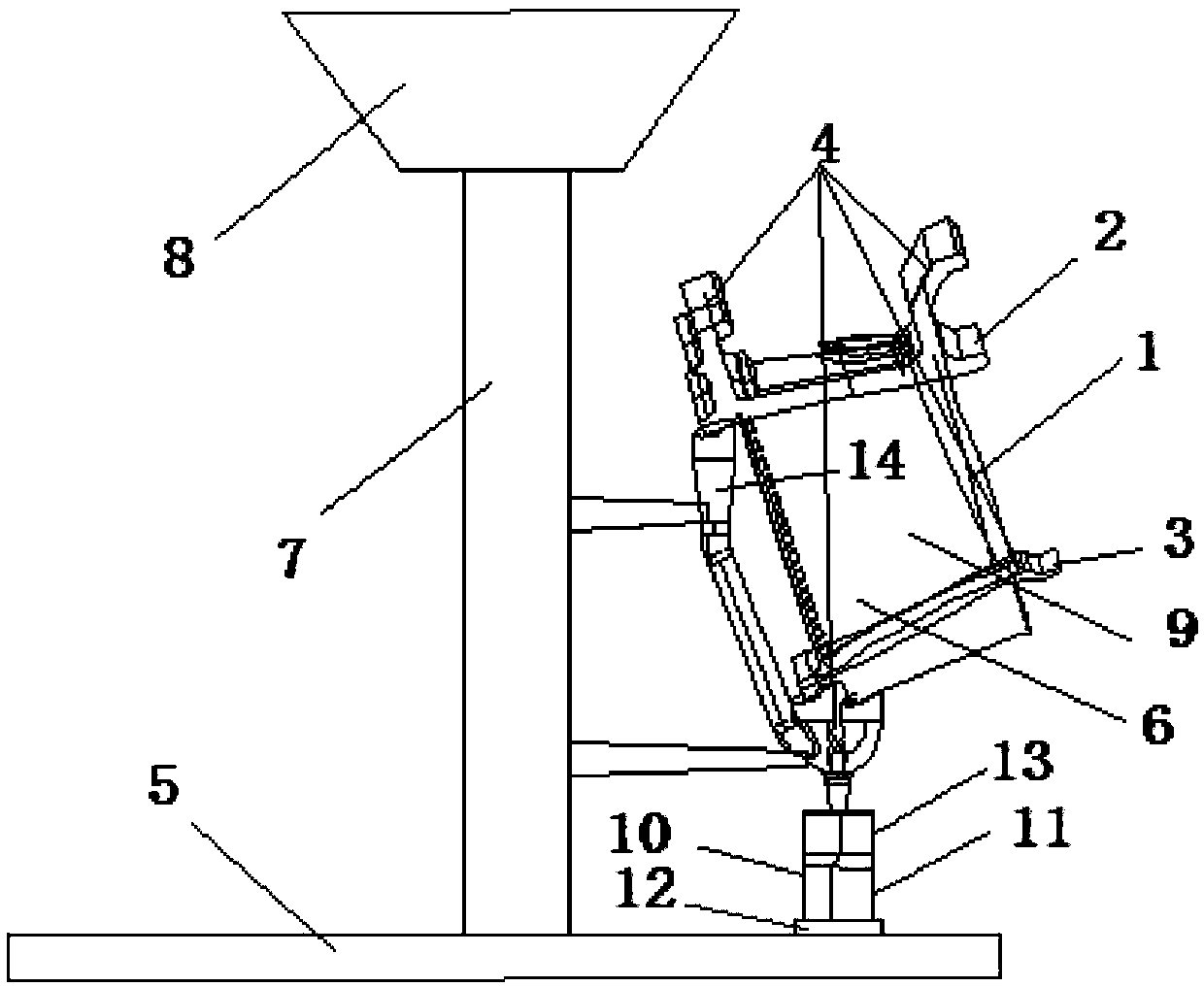

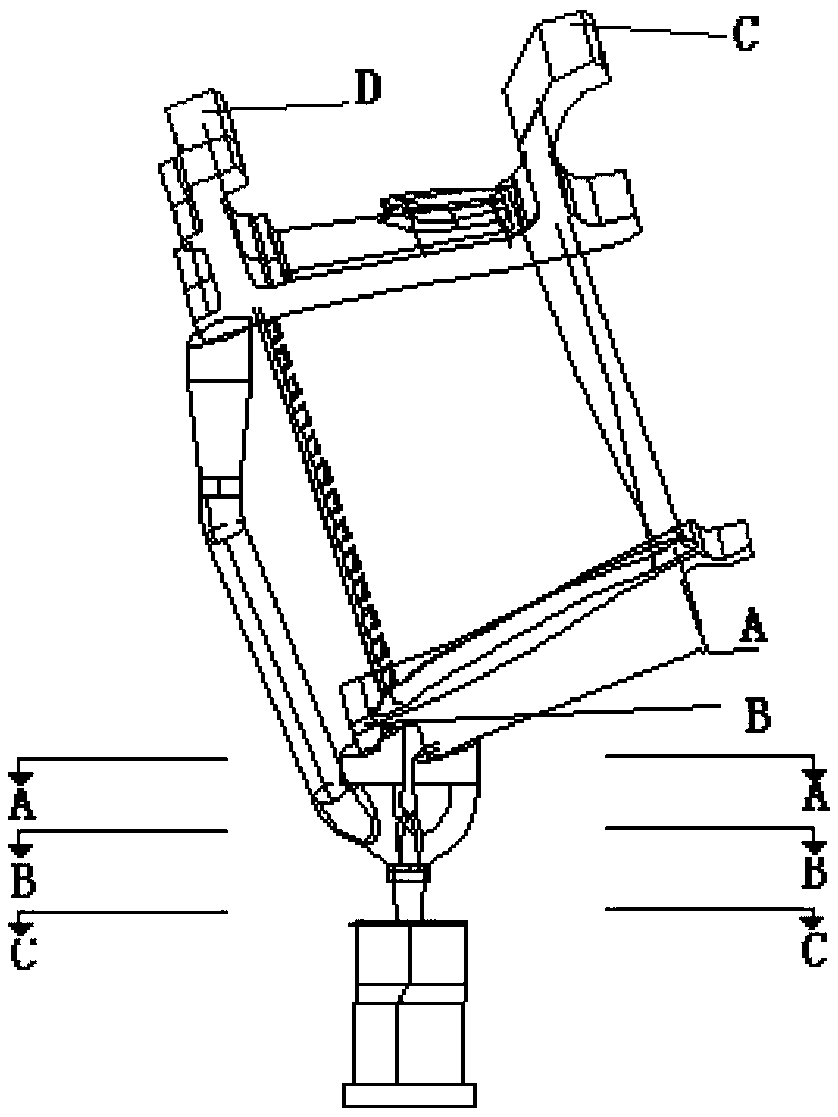

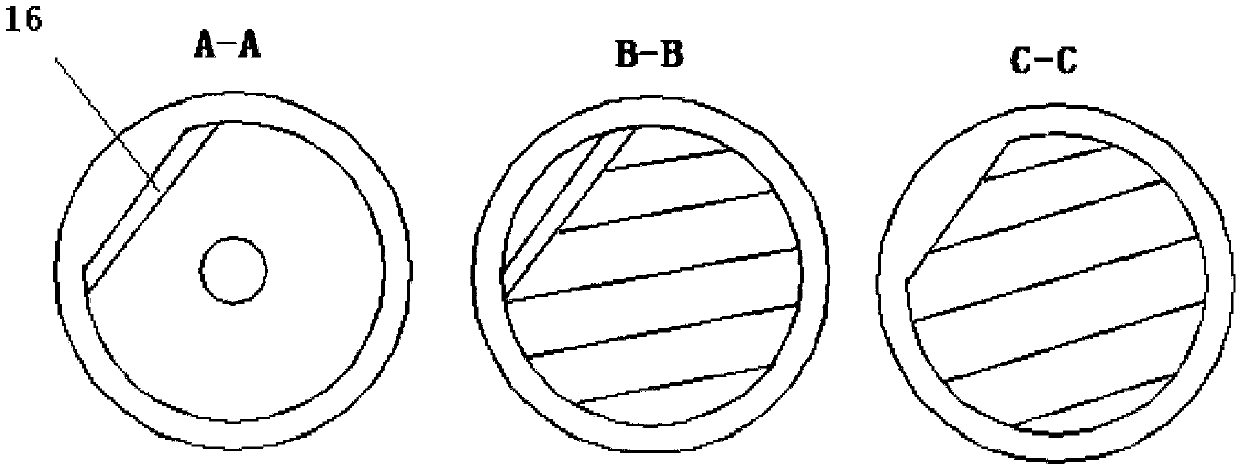

[0030] Such as figure 1 As shown, a nickel-based single crystal guide vane precision casting module that can precisely control the crystal orientation includes a subgroup tree structure 6 arranged on a bottom plate 5, a pouring system 7 and a sprue cup 8, and the sprue The cup 8 is arranged on the upper part of the pouring system 7, and the subgroup tree structure 6 is composed of two parts: the guide vane 9 and the grain generator 10. The guide vane 9 has a fan-shaped arc structure, including the blade body 1, the inner Arc shroud 2 , outer arc shroud 3 , lacing boss 4 ; the grain generator 10 includes a crystal raising section 13 , and the crystal raising section 13 is in contact with the lower end surface of the blade body 1 .

[0031] It also includes a seeding strip 14 for preventing miscellaneous crystals, and the seeding strip 14 is located in the space formed between the inner arc surrounding band 2, the outer arc surrounding band 3 and the rib boss 4 of the guide van...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap