Gravure connection line snowflake technology and curing system thereof

An in-line and snowflake technology, applied in the field of gravure in-line snowflake process and its curing system, can solve the problems of overprinting instability, influence on the quality and efficiency of printed matter, and fast speed of the gravure printing machine, so as to achieve stable ink blooming effect, The hue and effect are stable, and the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

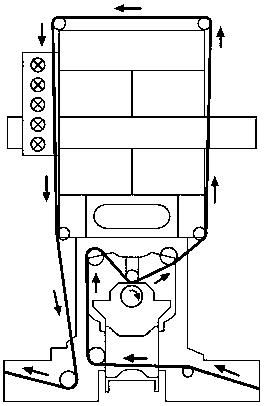

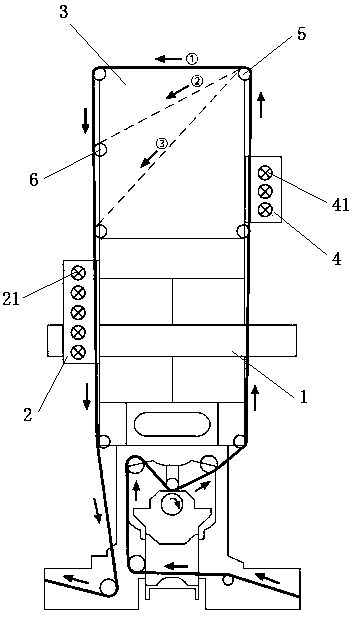

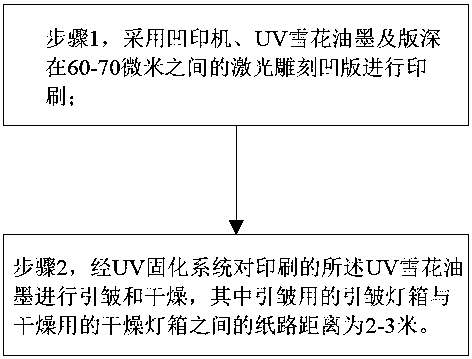

[0030] Such as figure 1 , 3 Shown, the present invention comprises the steps:

[0031] Step 1, use a gravure printing machine, UV snowflake ink and laser engraved gravure with a depth of 60-70 microns for printing;

[0032] In step 2, the printed UV snowflake ink is wrinkled and dried through a UV curing system, wherein the paper path distance between the wrinkle-inducing light box and the drying light box is 2-3 meters.

[0033] The speed of printing in the step 1 is 10000 sheets / hour-15000 sheets / hour. There are 2-3 corrugated lamps inside the corrugated light box, and the power of each corrugated lamp is 15KW. Each wrinkled lamp tube is controlled by a separate stepless adjustment switch. The drying light box is provided with 5 drying lamp tubes, and the power of each drying lamp tube is 15KW. Each drying lamp tube is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com