A control method of dendrite spacing during the growth process of Ni-based single crystal superalloy

A dendrite spacing, superalloy technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as dendrite coarsening, and achieve the effect of controlling dendrite coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

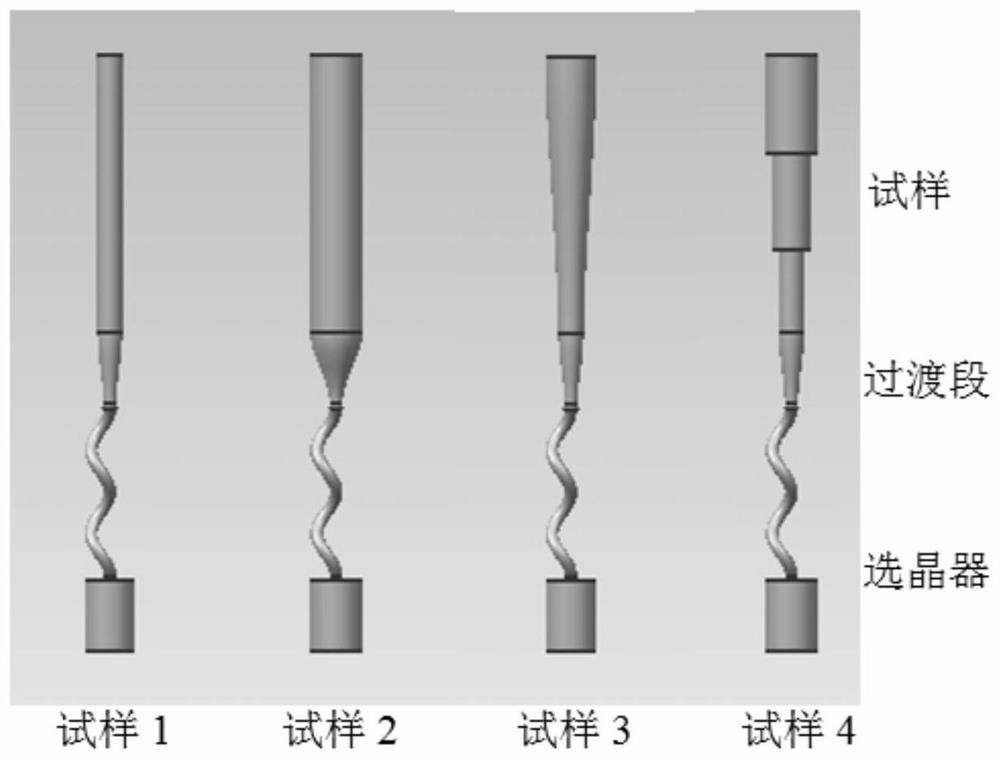

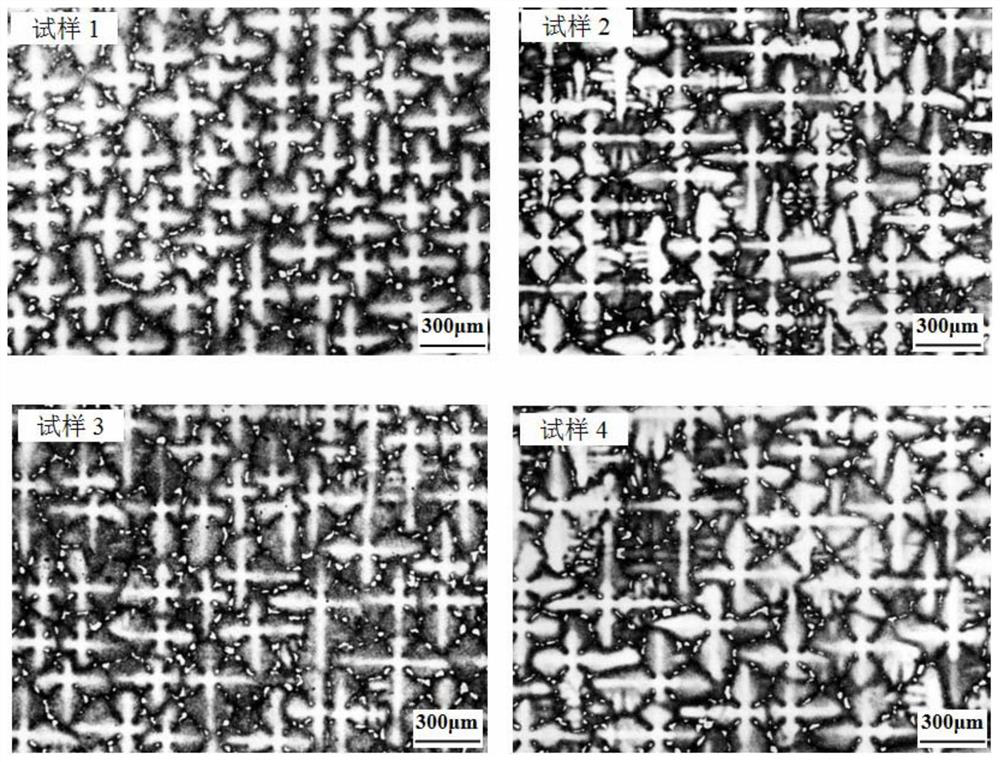

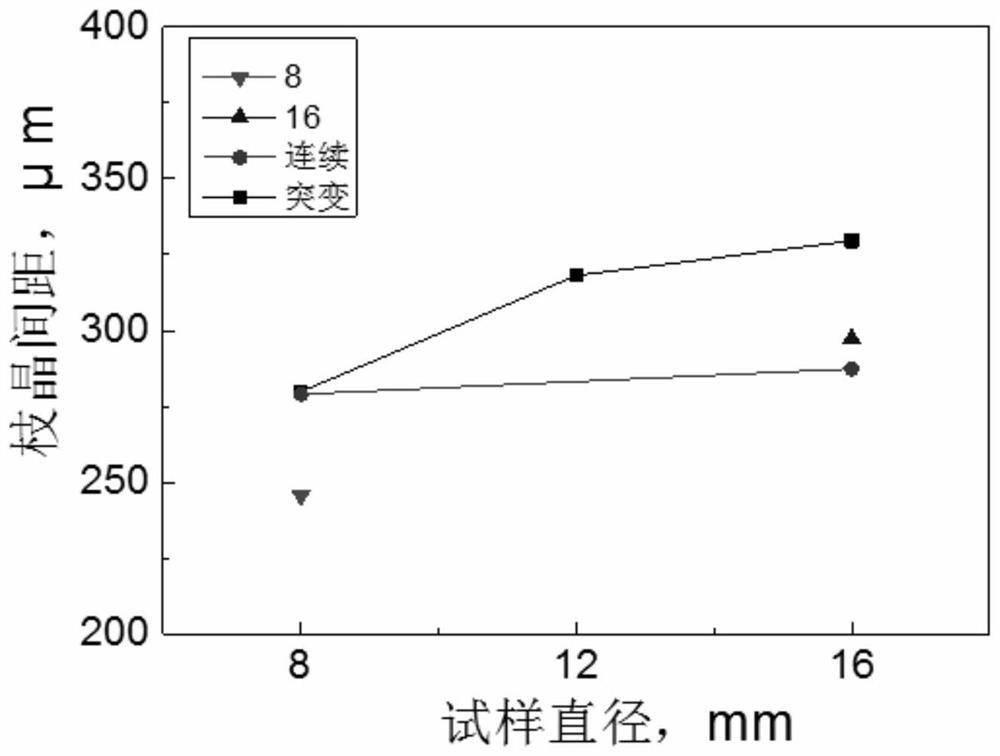

[0026] Such as figure 2 As shown, under the condition that the directional solidification process is unchanged, the dendrite growth path is different with the different sample size, resulting in different dendrite spacing in the single crystal test bar. Such as image 3 As shown, when the dendrite grows in the sample 1 with a size of φ8, the dendrites are fine and dense, and the dendrite spacing is about 246μm; when the dendrites grow in the sample 2 with a size of φ16, the dendrites are significantly coarsened , The dendrite spacing is about 297μm; when the dendrite is grown in sample 3 with a size of φ8-16 continuously expanded, the dendrite morphology is similar to that of sample 3, and the dendrite spacing is about 287μm; when the dendrite is in size When growing in sample 4 with a φ8-16 mutation expansion, the dendrites are coarser, and the dendrite spacing is about 330μm. When the sample size is in the range of φ8-16mm, as the sample size increases, the dendrite spacing ...

Embodiment 2

[0028] According to the difference between the dendrite spacing in different growth paths of dendrite in Example 1, adjust the single crystal growth mode in the simulated blade, from the top tenon to the bottom tenon, such as Figure 4 Shown. Due to the different growth methods, the dendrite spacing in the leaves also has significant differences. Figure 5 It is the dendrite morphology of leaf simulation pieces with different growth methods. In the blade simulation part of the tenon-up growth mode, the dendrite is relatively fine and dense, and the dendrite spacing is about 280μm; in the blade simulation part of the tenon-down growth mode, the dendrite is relatively coarse, and the dendrite spacing is about 300μm. Therefore, by changing the growth mode of the blade simulation piece, the goal of controlling the dendrite spacing can be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com