A factory intelligent inspection system based on lora technology

A factory and technology technology, applied in the field of factory intelligent inspection system, can solve the problems of high price of deploying intelligent inspection system, unstable WIFI signal, difficult factory circuit reconstruction, etc., to maintain equipment in good condition, easy to construct and deploy, The effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

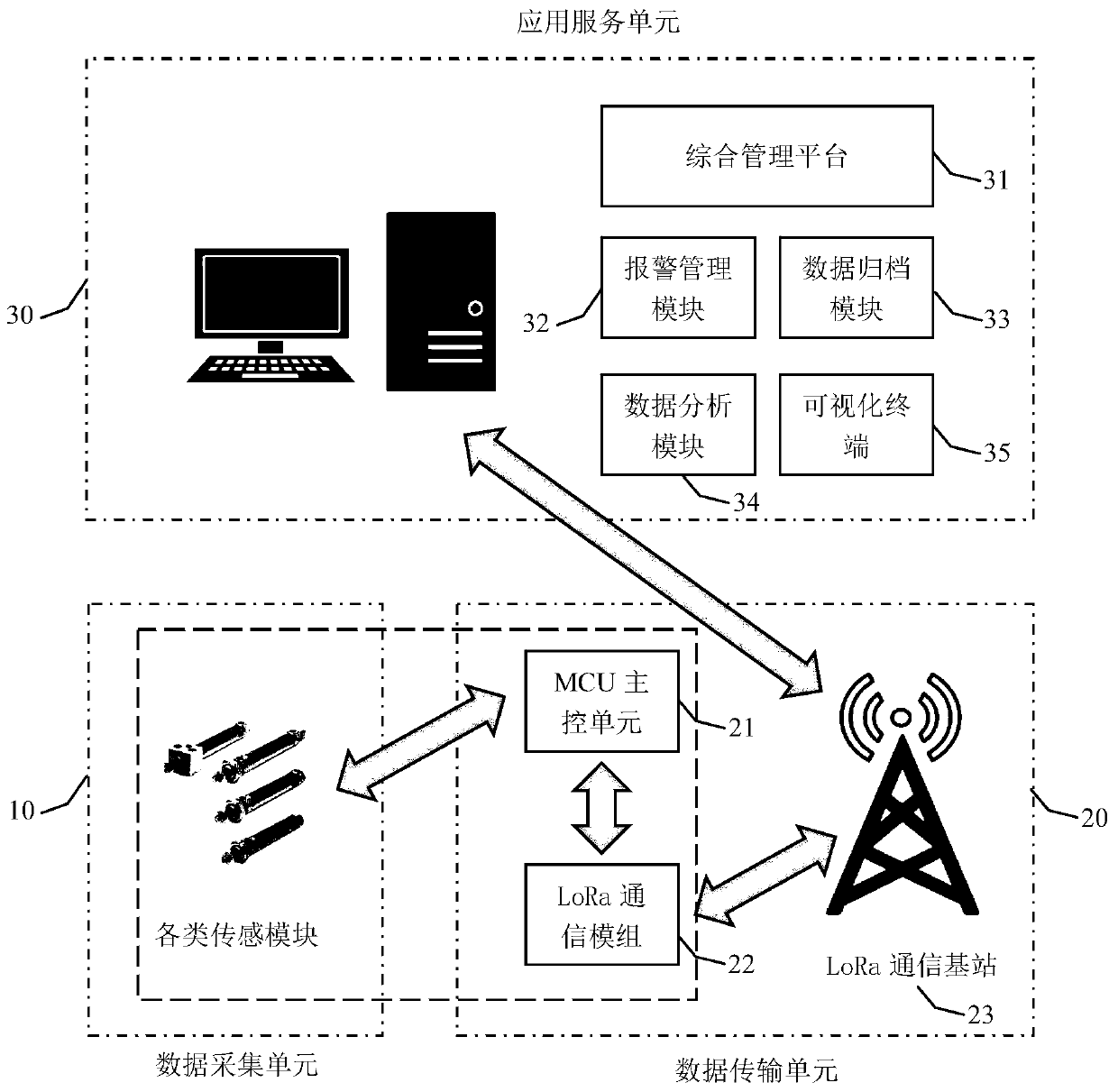

Method used

Image

Examples

example 2

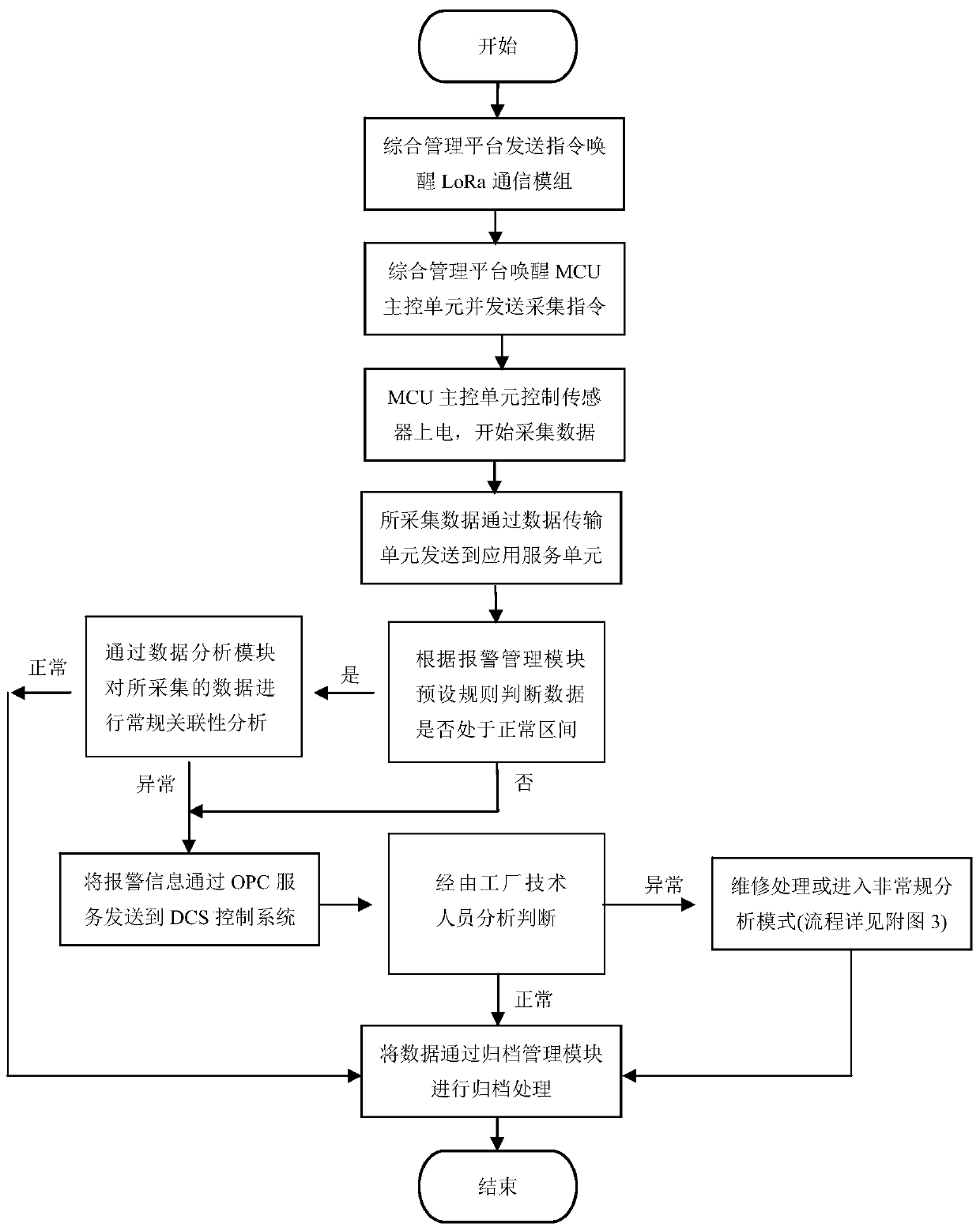

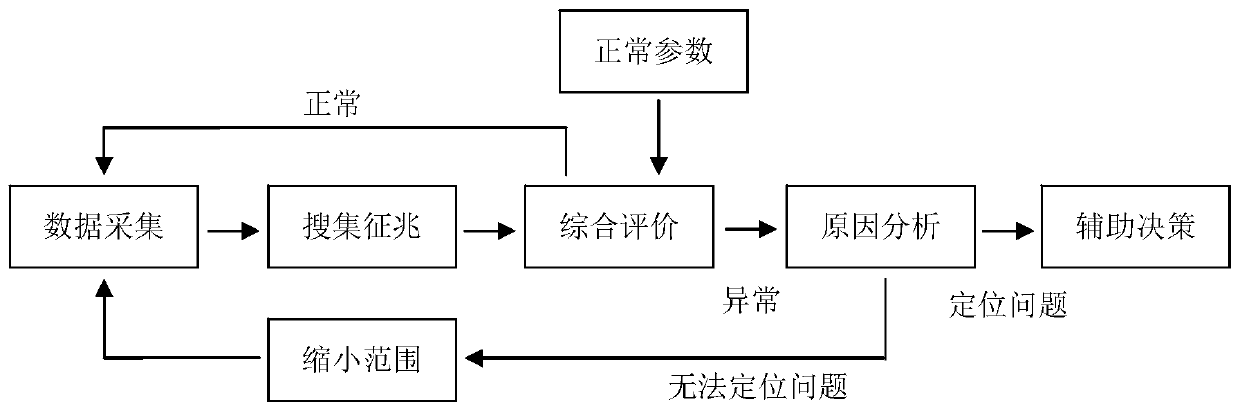

[0043] Further, the working process of the alarm management module 32 and the data analysis module 34 is illustrated with an example. Example 1: The alarm management module 32 presets the normal state information rules of the equipment according to the actual situation: the bearing temperature of the motor60°C and 70 ℃ warning level "Level 2", radial vibration >8mm / s and 12mm / s warning level "Level 2"; The motor works in "Position A". On-site information collected by the data acquisition unit 10 twice in a row: the bearing temperature of the motor is 55° C., the radial vibration is 10 mm / s, the bearing temperature is 65° C., and the radial vibration is 13 mm / s. Then the alarm management module 32 judges the above two collected information as follows: the first time "warning level: level one, warning type: vibration, warning content: motor radial vibration 10mm / s, warning position: position A", The second time "warning level: level two, warning type: temperature, vibration, wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com