Fiber-reinforced multi-spray-head cement paste 3D printing machine

A 3D printer, fiber reinforced technology, applied in the field of additive manufacturing, can solve the problems of coagulation time, model structure characteristics, printing speed difficult to coordinate, high accuracy requirements of material solidification characteristics, poor surface quality, etc., to improve printing efficiency, The effect of fast forming speed and high forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and concrete implementation the utility model is further described:

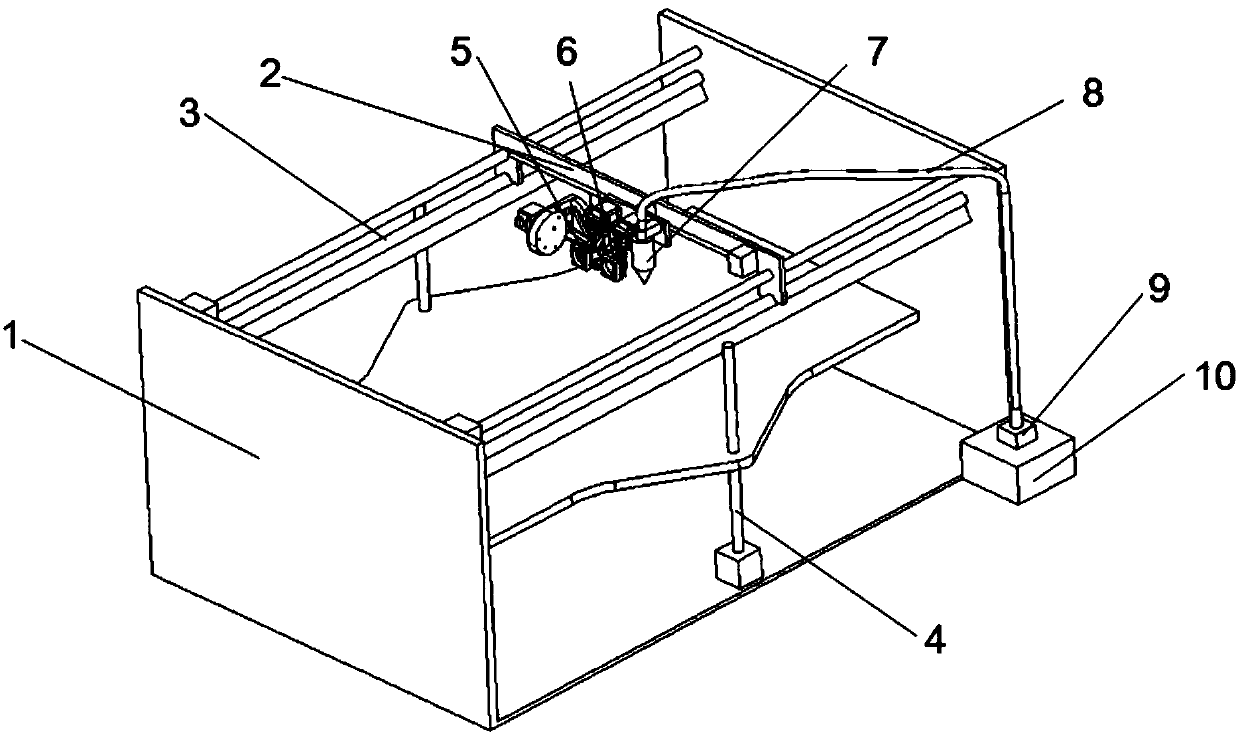

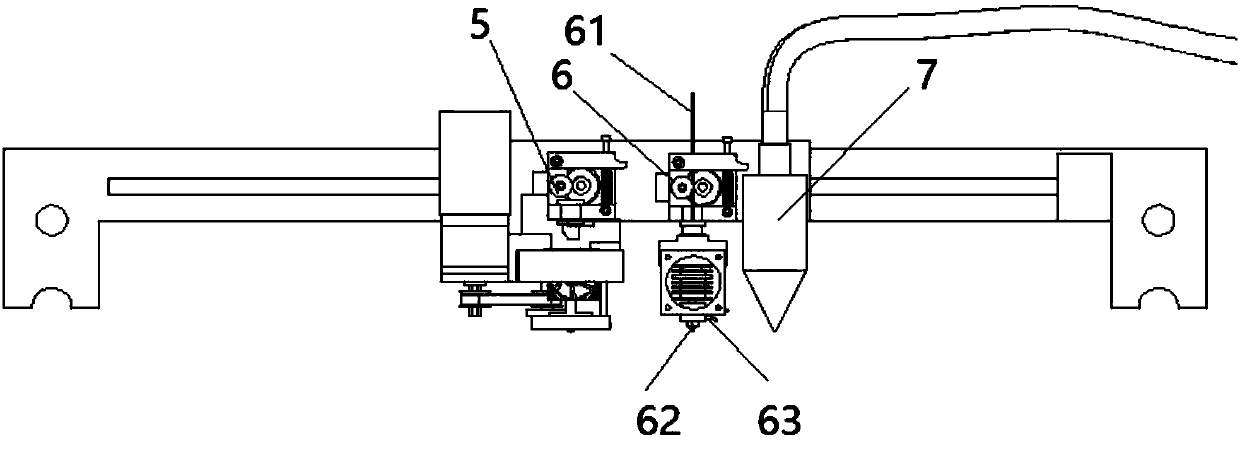

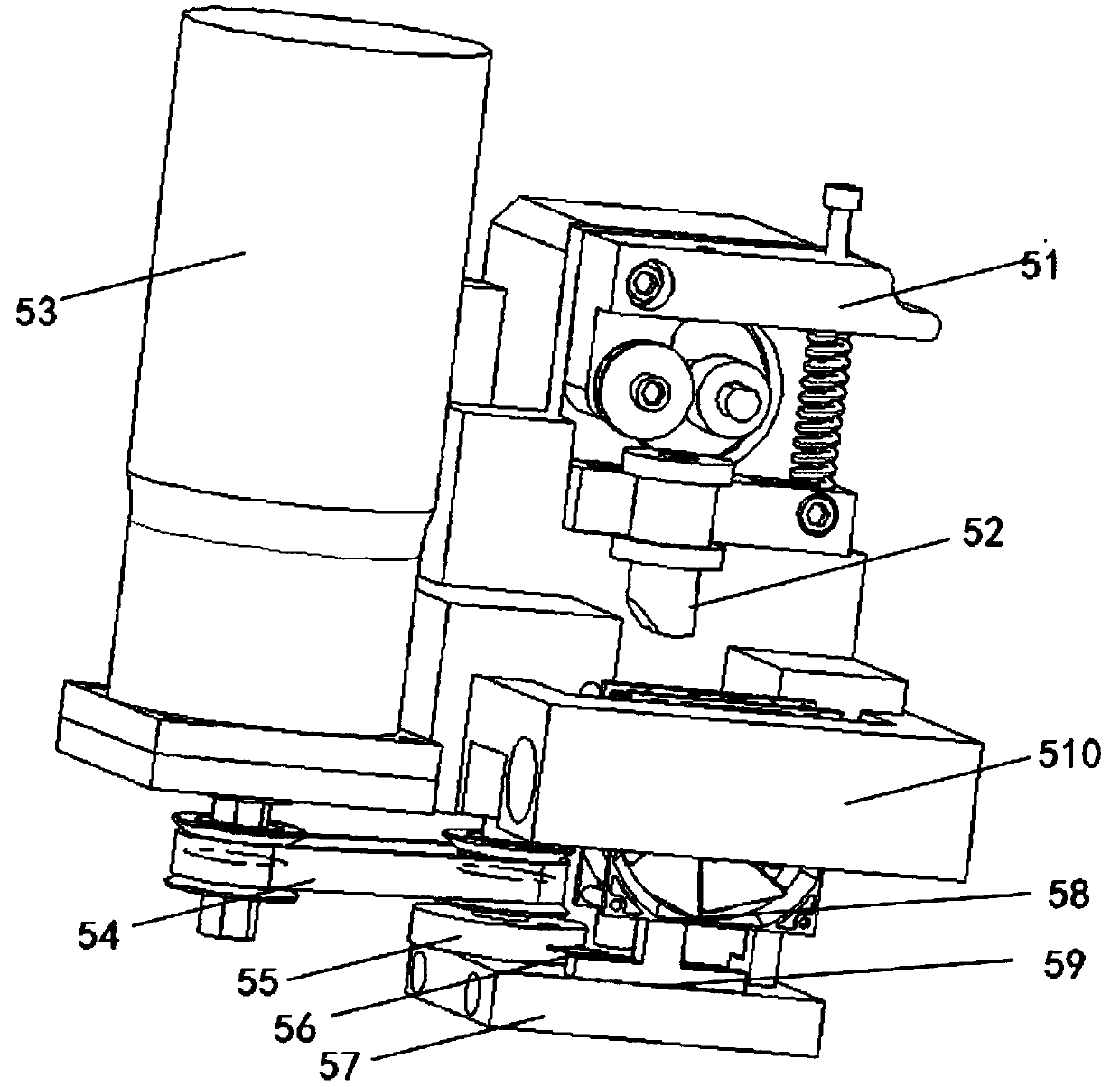

[0028] The structure of the present invention is as attached figure 1 As shown, it includes gantry frame 1, X-axis moving mechanism 2, Y-axis moving mechanism 3, Z-axis moving platform 4, fiber composite material nozzle 5, polymer material nozzle 6, cement slurry nozzle 7, material conduit 8, pressure Pump 9, storage tank 10. Fiber composite material nozzle 5, polymer material nozzle 6, and cement slurry nozzle 7 are arranged side by side on the X-axis moving mechanism 2 of the gantry frame 1, and the three nozzles work together to complete the three-dimensional molding of cement slurry. The polymer material nozzle 6 uses polymer materials as printing materials, such as polylactic acid, nylon, etc., and prints the outline of the three-dimensional model through FDM layer by layer, and the interior is a hollow structure. The cement slurry nozzle 7 uses ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com