Lightweight partition board maintenance method

A light-weight partition board, steam curing technology, applied in the field of wall processing and production, can solve the problems of cracking, poor water resistance, low strength, etc., and achieve the effect of simple process, good durability and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

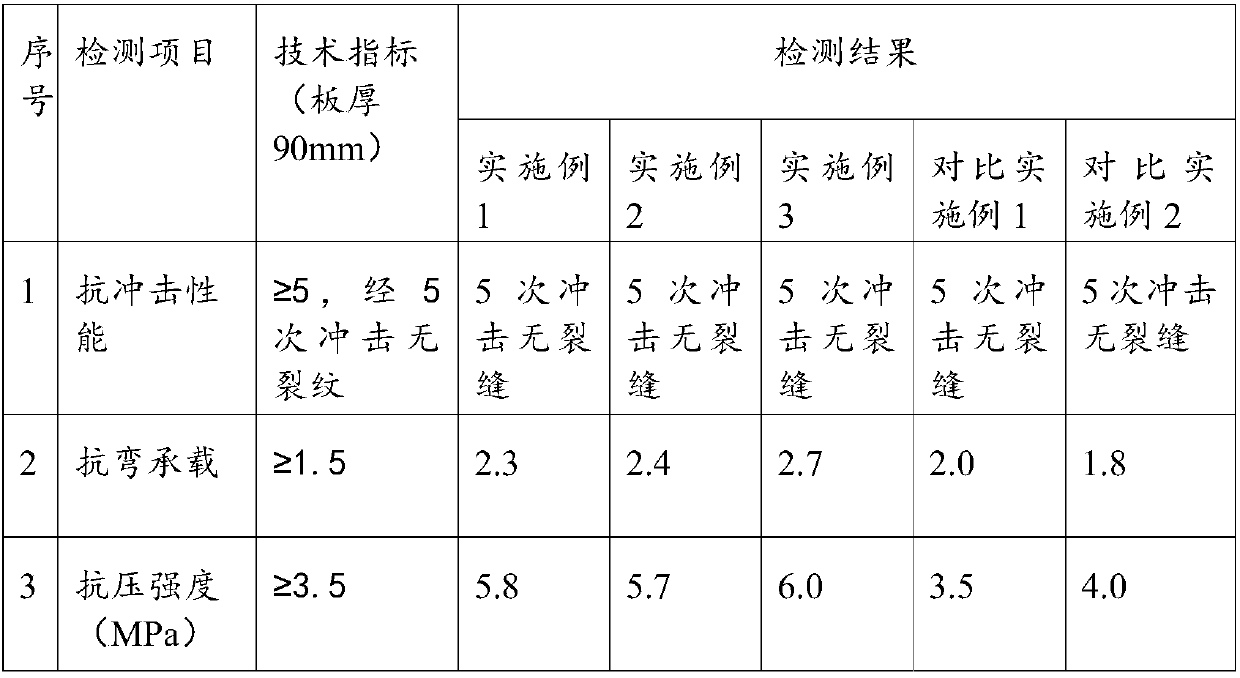

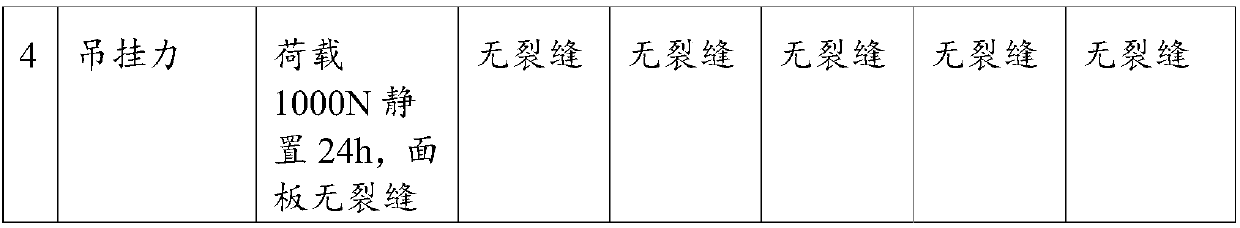

Examples

preparation example Construction

[0024] (1) Preparation of lightweight partition board mixture

[0025] Weigh 65 parts of Portland cement, 3 parts of polypropylene fiber, 2 parts of cellulose, 1.5 parts of polyvinyl alcohol, 4 parts of waterproofing agent, 8 parts of foaming agent and 3 parts of non-burning ceramic powder by weight; Put the raw materials other than the foaming agent into the cement mixing tank, add an appropriate amount of water, and stir evenly to obtain a mixed slurry; add an appropriate amount of water to the foaming agent, mix evenly, and then put it into a foaming machine for foaming to obtain a stable structure. After foaming, the obtained foam and the prepared mixed slurry are poured into a foam mixing machine, during which the stirring is continued to obtain a lightweight partition wall board mixture.

[0026] The waterproofing agent is made by mixing stearic acid, soda ash, sodium hydroxide and sodium alkylbenzene sulfonate with a mass ratio of 50:6:1.5:1; the foaming agent is made b...

Embodiment 1

[0029] A maintenance method for a lightweight partition board, comprising a steam curing stage and a curing stage after demoulding, the specific steps of the steam curing stage are as follows: send the forming mold filled with the lightweight partition board mixture to In the steaming room, it is divided into heating, constant temperature and cooling stages according to the temperature. The heating stage is also divided into three stages in turn: the first stage is heated to 30°C, the relative humidity is 70%, and the temperature is kept for 25 minutes; the second stage is heated to 45°C. ℃, relative humidity is 80%, keep warm for 15min; in the third stage, the temperature is raised to 50℃, the relative humidity is 80%, and then enters the constant temperature stage; The relative humidity is 60%; the three stages of heating, constant temperature and cooling stage are cured for 20 hours in total, and then the demoulding is carried out, and the curing stage after demoulding is en...

Embodiment 2

[0031] A maintenance method for a lightweight partition board, comprising a steam curing stage and a curing stage after demoulding, the specific steps of the steam curing stage are as follows: send the forming mold filled with the lightweight partition board mixture to In the steaming room, it is divided into heating, constant temperature and cooling stages according to the temperature. The heating stage is also divided into three stages in turn: the first stage is heated to 35°C, the relative humidity is 80%, and the temperature is kept for 20 minutes; the second stage is heated to 55°C. ℃, relative humidity is 85%, keep warm for 10min; in the third stage, the temperature is raised to 60℃, the relative humidity is 85%, and then enters the constant temperature stage; The relative humidity is 70%; the three stages of heating, constant temperature and cooling are maintained for 24 hours in total, and then the demoulding is carried out, and the post-demolding maintenance stage is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com