Treatment method for waste paint of furniture paint spraying

A treatment method and paint technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of no raw water-based coatings, economic losses, and the inability to change the color of recyclables, and achieve good antibacterial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

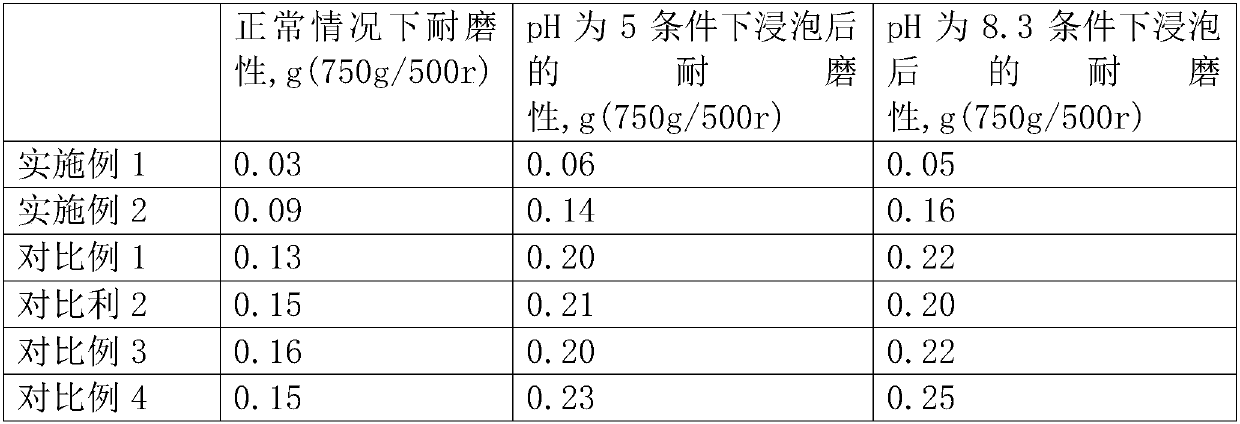

Examples

Embodiment 1

[0036] Embodiment 1: A waste paint treatment method for furniture paint spraying, characterized in that it comprises the following steps:

[0037] Step 1: Use a waste liquid bucket to collect waste paint, then pour the collected waste paint into a large beaker, add excess deionized water to the large beaker, and make the waste paint completely dissolved;

[0038] Step 2: After standing for 4-5 hours, remove the suspended matter floating on the surface of the paint. After removal, use a microfiltration membrane to filter the waste paint, and repeat the filtration 3 times to obtain a filtrate;

[0039] Step 3: Add 3-5 grams of antibacterial agent to the filtrate, the solution temperature is set to 40-60 ℃, while stirring with a mixer, the stirring speed is 100-200r / min, the stirring time is 10-20min;

[0040] Step 4: Then place the filtrate under ultraviolet light for 2-3 hours;

[0041] Step 5: Dry the filtrate in an oven, the temperature of the oven is set to 80-100°C, and the drying ti...

Embodiment 2

[0065] 1. A waste paint treatment method for furniture paint spraying, characterized in that it comprises the following steps:

[0066] Step 1: Use a waste liquid bucket to collect waste paint, then pour the collected waste paint into a large beaker, add excess deionized water to the large beaker, and make the waste paint completely dissolved;

[0067] Step 2: After standing for 4-5 hours, remove the suspended matter floating on the surface of the paint. After removal, use a microfiltration membrane to filter the waste paint, and repeat the filtration 3 times to obtain a filtrate;

[0068] Step 3: Add 3-5 grams of antibacterial agent to the filtrate, the solution temperature is set to 40-60 ℃, while stirring with a mixer, the stirring speed is 100-200r / min, the stirring time is 10-20min;

[0069] Step 4: Then place the filtrate under ultraviolet light for 2-3 hours;

[0070] Step 5: Dry the filtrate in an oven, the temperature of the oven is set to 80-100°C, and the drying time is 1-2 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com