A kind of refining method of aluminum-silicon series cast aluminum alloy

A technology for casting aluminum alloys and aluminum-silicon systems, applied in the field of metal materials, can solve problems such as reducing the cleanliness of aluminum alloy ingots, achieve the effects of reducing wettability, improving quality, and strengthening refining effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

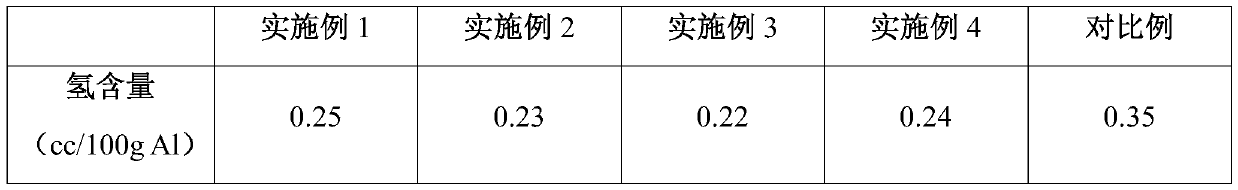

Examples

Embodiment 1

[0022] A method for refining aluminum-silicon-based cast aluminum alloys, comprising the steps of:

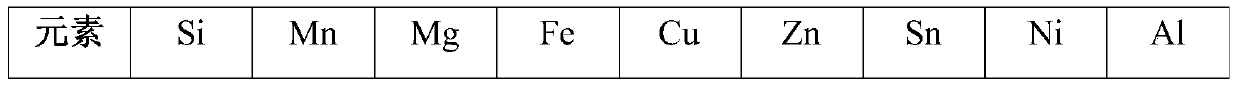

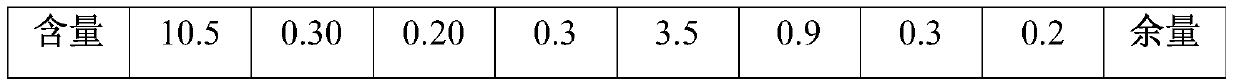

[0023] A. Ingredients: The mass percentage ratio of each element in the aluminum alloy ingot raw material is as follows:

[0024]

[0025]

[0026] The various raw material components of the above-mentioned mass parts are weighed according to the mass percentage and prepared;

[0027] B. Melting: Put all the raw material components weighed in step A into the melting furnace for smelting. Thinning, degassing, filtering, casting;

[0028] C, deslagging and degassing: take by weighing a certain quality dried alum KAl(SO 4 ) 2 12H 2 O, put the alum dried in the oven and nitrogen with a purity of 99.5% into the molten aluminum through a spray gun, wherein the addition rate of the alum is 10% kg / tAl, and the nitrogen is injected into the molten aluminum through the graphite rotor, and the nitrogen from the smelting The bottom of the furnace is fed into the furnace. During ...

Embodiment 2

[0032] The difference between embodiment 2 and embodiment 1 is that the ratio of the mass percentage of each element in the aluminum alloy ingot raw material in step A is as follows:

[0033] element Si mn Mg Fe Cu Zn sn Ni Al content 11.5 0.50 0.30 0.60 3.5 0.9 0.3 0.5 margin

Embodiment 3

[0035] The difference between embodiment 3 and embodiment 1 is that the ratio of the mass percentage of each element in the aluminum alloy ingot raw material in step A is as follows:

[0036] element Si mn Mg Fe Cu Zn sn Ni Al content 11 0.40 0.25 0.4 3.0 0.6 0.25 0.3 margin

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com