Mg-Al-Ni series hydrogen storage particle and catalytic modification preparation method thereof

A hydrogen storage and particle technology is applied in the field of Mg-Al-Ni hydrogen storage materials and their preparation, and can solve the problem of high hydrogen absorption temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

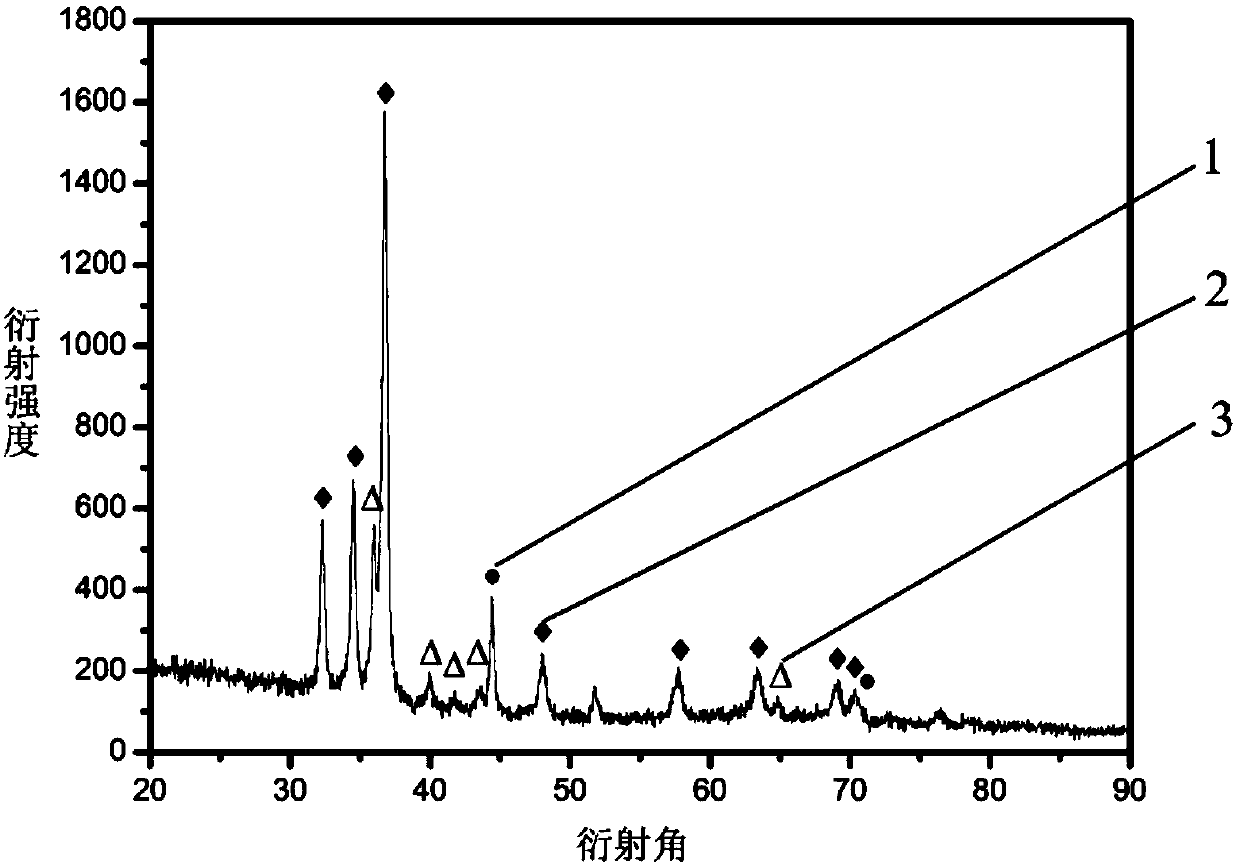

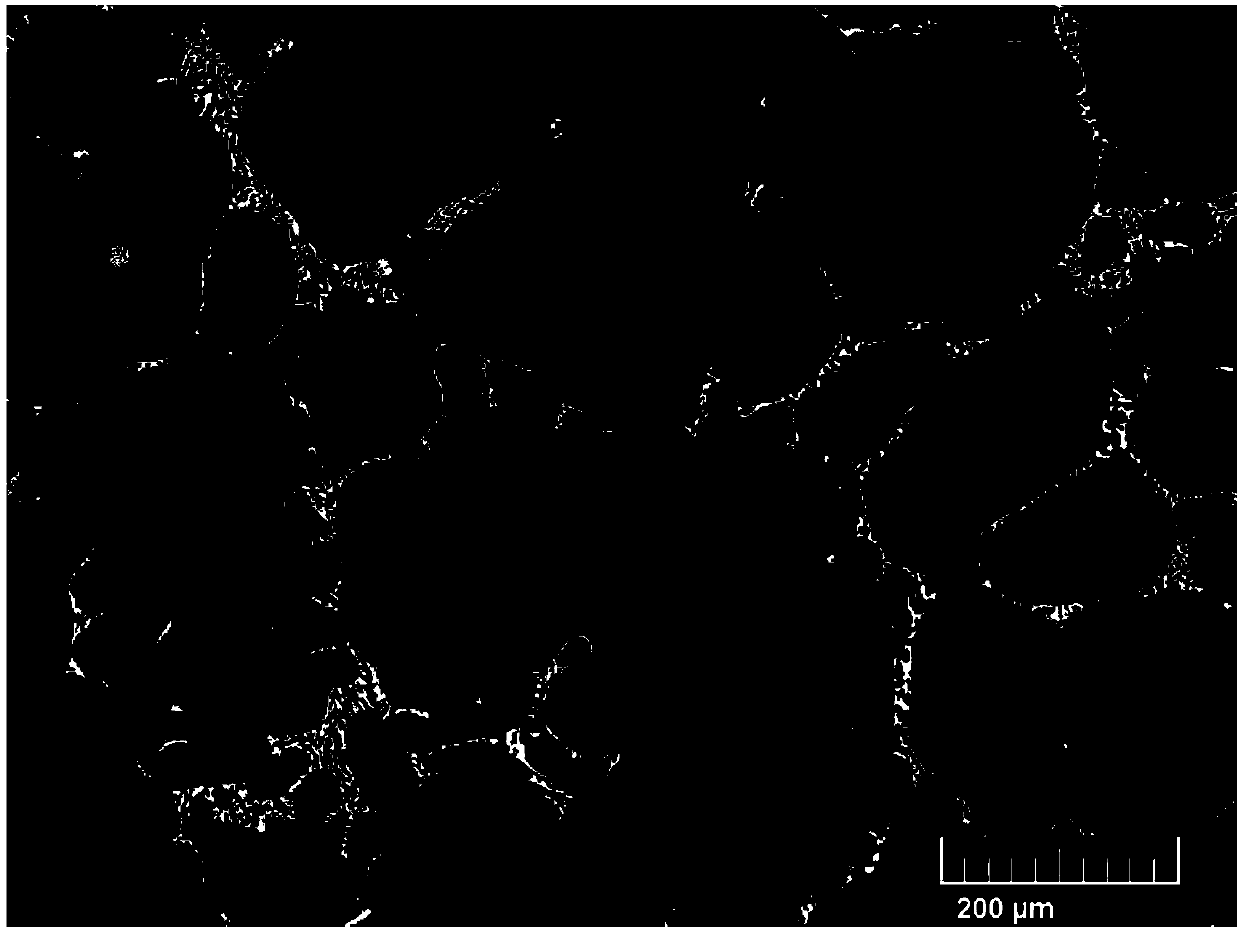

Embodiment 1

[0037] This embodiment is a kind of Mg-Al-Ni hydrogen storage particles, which are composed of 80 wt.% Mg, 15 wt.% Al and 5 wt.% Ni. The Mg15Al5Ni alloy particles described in this embodiment select bulk Mg with a purity of ≥99.9 wt.%, bulk Al, and powdered Ni with a purity of ≥99.9 wt.%.

[0038] The preparation process of the Mg15Al5Ni alloy ingot proposed in this embodiment is as follows:

[0039] The first step is surface treatment. The surface treatment of the raw materials will remove oil stains and surface oxide scales from the weighed Mg and Al.

[0040] The second step is to prepare Mg15Al alloy ingots. The Mg15Al alloy ingot is prepared by using the well-type resistance furnace and the covering agent protection method. The present invention uses the second covering agent commonly used in industry. The specific process is to weigh 85 wt.% Mg and 15 wt.% Al. In order to prevent the composition deviation caused by the volatilization of magnesium, an additional 5 wt.% of ma...

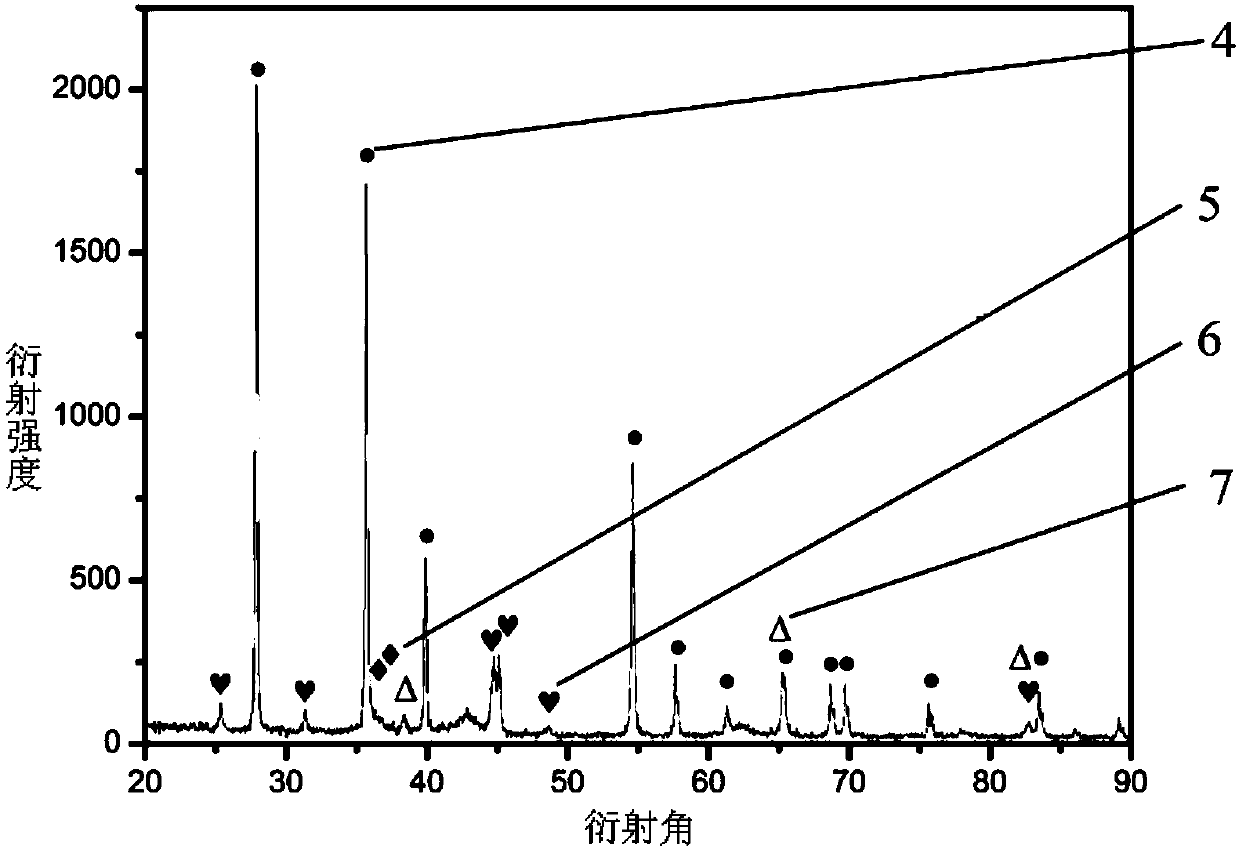

Embodiment 2

[0049] This embodiment is a kind of Mg-Al-Ni hydrogen storage particles, which are composed of 75 wt.% Mg, 20 wt.% Al and 5 wt.% Ni. In this embodiment, a Mg20Al alloy ingot is prepared in advance by the covering agent protection method, and then Mg20Al5Ni alloy particles are prepared by the high-energy ball milling method. The Mg20Al5Ni alloy particles described in this embodiment select bulk Mg with a purity of ≥99.9 wt.%, bulk Al, and powdered Ni with a purity of ≥99.9 wt.%.

[0050] The preparation process of the Mg20Al5Ni alloy ingot proposed in this embodiment is as follows:

[0051] The first step is surface treatment. The surface treatment of the raw materials will remove oil stains and surface oxide scales from the weighed Mg and Al.

[0052] The second step is to prepare Mg20Al alloy ingots. The Mg20Al alloy ingot is prepared by using the well-type resistance furnace and the covering agent protection method. The present invention uses the second covering agent commonly ...

Embodiment 3

[0061] This embodiment is a kind of Mg-Al-Ni hydrogen storage particles, which are composed of 85 wt.% Mg, 10 wt.% Al, and 5 wt.% Ni. In this embodiment, a Mg10Al alloy ingot is prepared in advance by a covering agent protection method, and then Mg10Al5Ni alloy particles are prepared by a high-energy ball milling method. The Mg10Al5Ni alloy particles described in this embodiment select bulk Mg with a purity of ≥99.9 wt.%, bulk Al, and powdered Ni with a purity of ≥99.9 wt.%.

[0062] The preparation process of the Mg10Al5Ni alloy ingot proposed in this embodiment is as follows:

[0063] The first step is surface treatment. The surface treatment of the raw materials will remove oil stains and surface oxide scales from the weighed Mg and Al.

[0064] The second step is to prepare Mg10Al alloy ingots. The Mg10Al alloy ingot is prepared by using the well-type resistance furnace and the covering agent protection method. The present invention uses the second covering agent commonly use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com