Powder metallurgy sintering method for bearing cover

A sintering method and powder metallurgy technology, applied in the field of powder metallurgy, can solve the problems of tensile strength, yield strength, elongation, and density that cannot meet the requirements of drawings at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

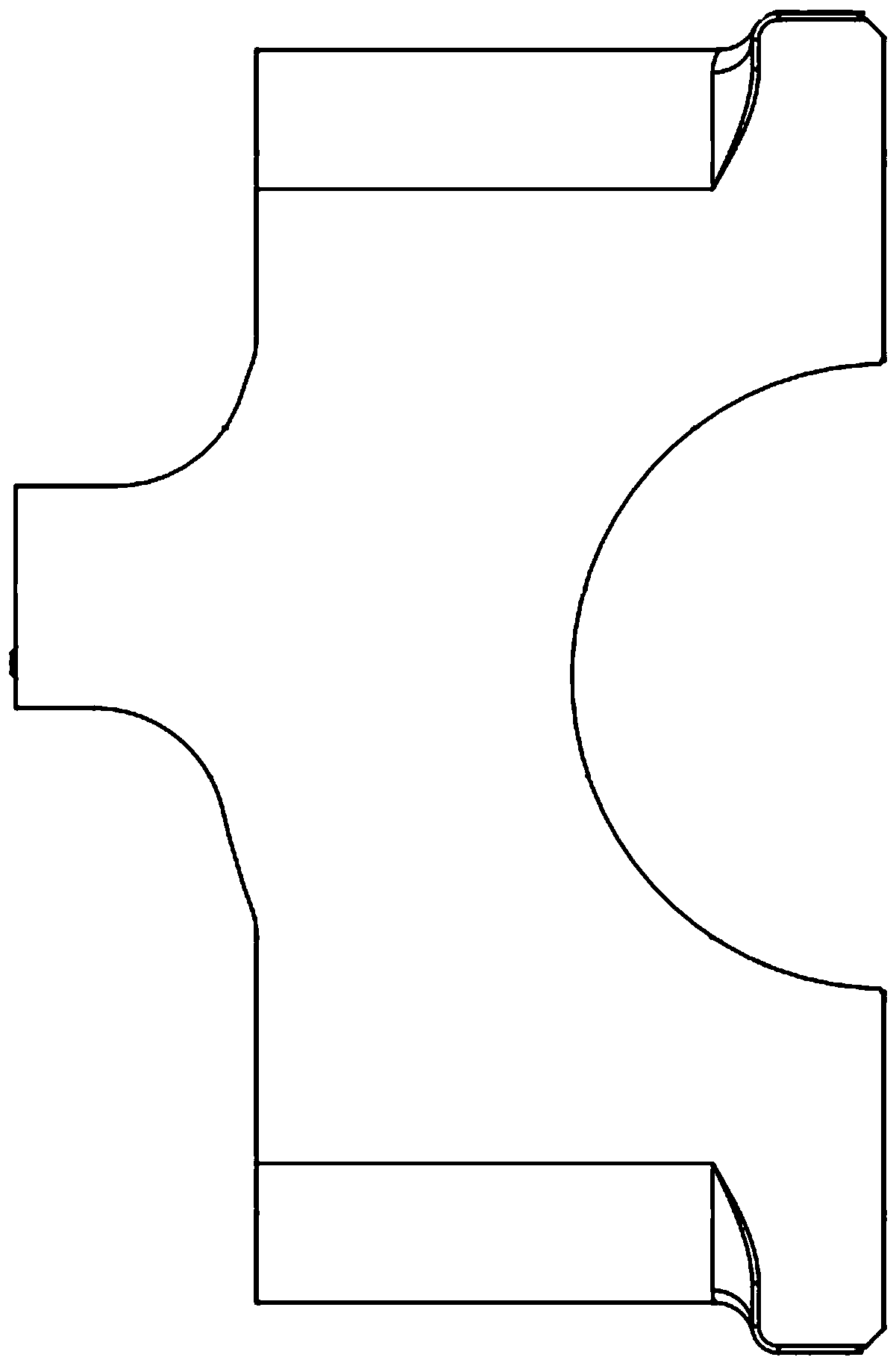

Image

Examples

Embodiment Construction

[0019] The specific implementation of the powder metallurgy sintering method for the bearing cap of the present invention will be described in detail below with reference to the accompanying drawings.

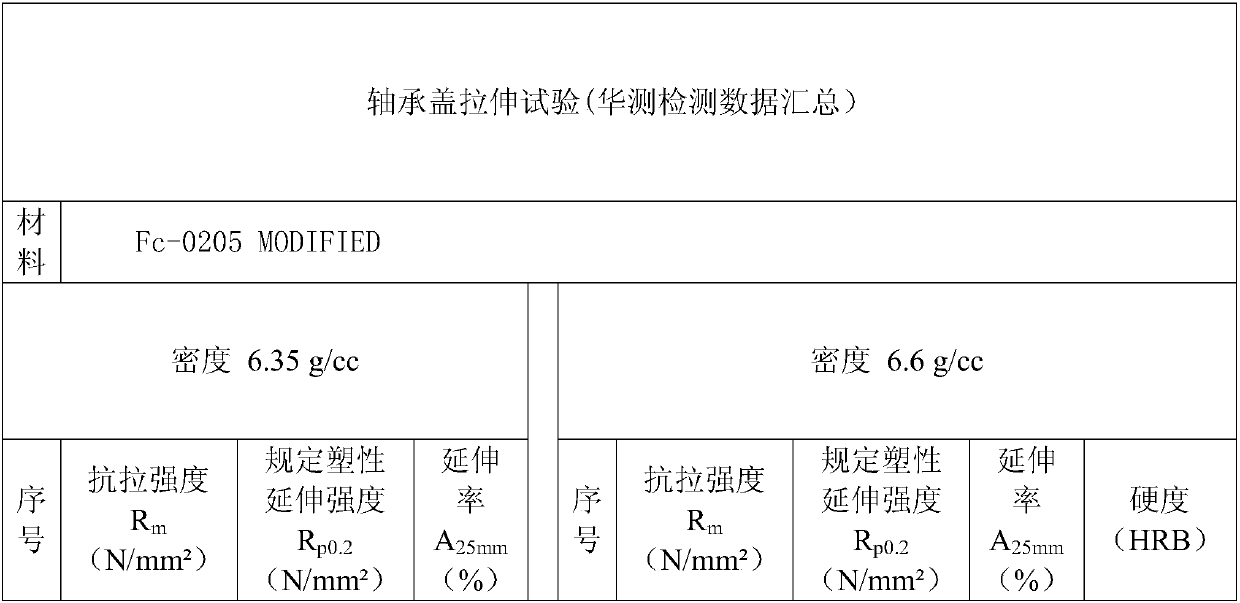

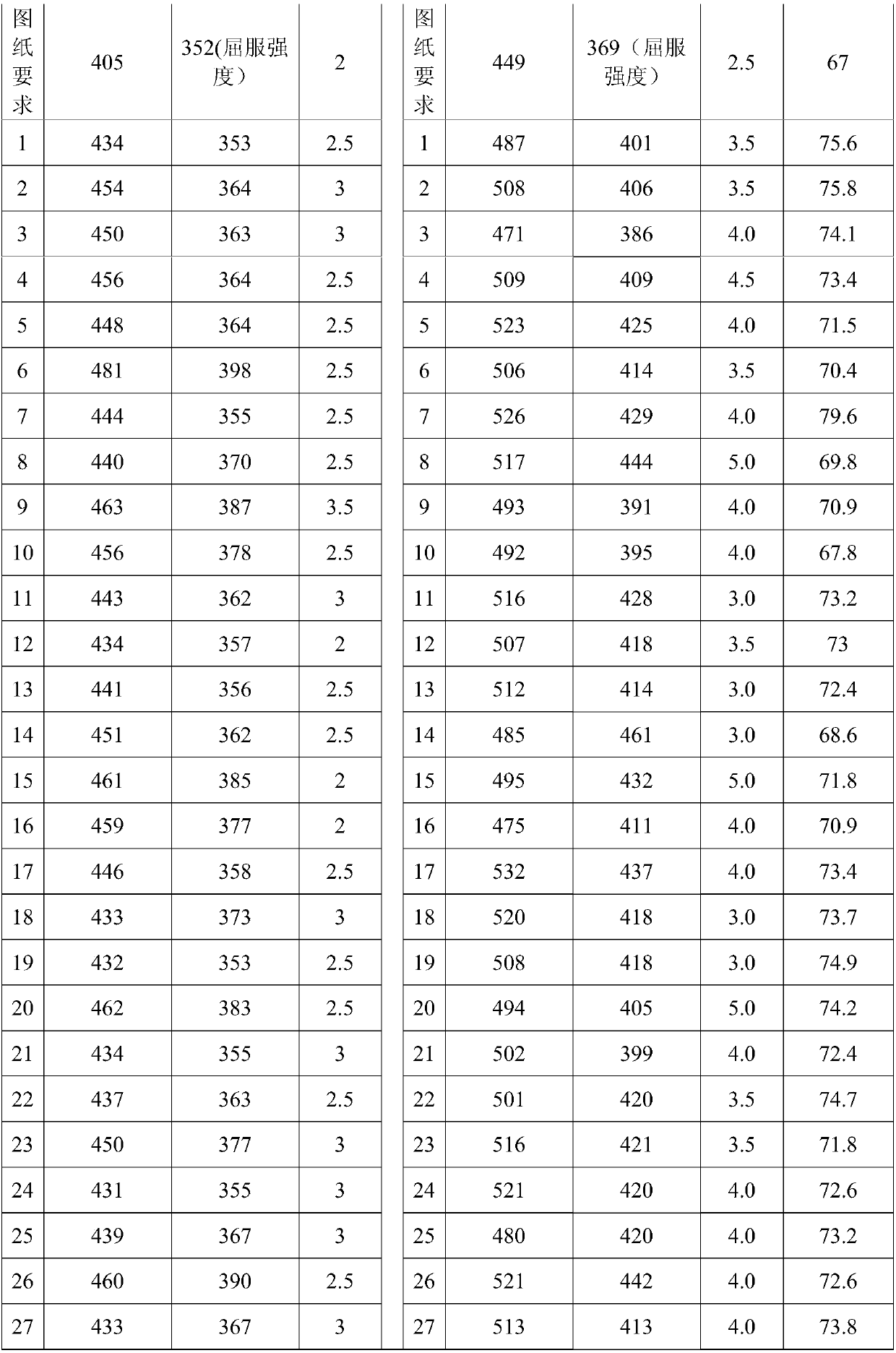

[0020] The bearing cap material involved in the present invention is a modified version of the standard material. The element P is added on the basis of the conventional Fe-C-Cu material. Since P can form an interstitial solid solution with Fe, it can achieve solid solution strengthening, pore spheroidization and activation Sintering and other functions. Adding a certain amount of P can make the iron-based material obtain higher strength and hardness, but at the same time P also drastically reduces the plasticity and toughness, especially the low temperature toughness, so high strength and high elongation must be achieved at the same time. The conventional sintering method Is not feasible.

[0021] Through the modification of the material formula and the sintering furnace, the prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com