Method for removing aluminum from anodizing chemical-polishing effluent and recycling system

A technology of anodic oxidation and waste liquid, which is applied in the field of aluminum removal method and recovery system of anodized waste liquid, which can solve the problems of a large amount of acid-containing and aluminum-containing rinsing wastewater, large consumption of chemical agents, sludge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

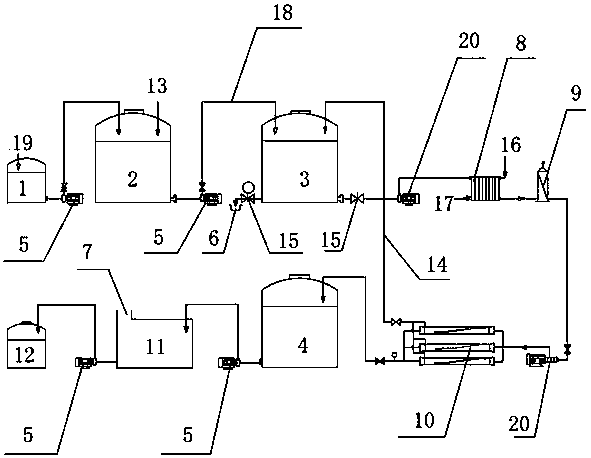

[0019] A method for removing aluminum from anodized waste liquid, comprising the following steps: a, mixing the aged chemical waste liquid and rinsing water containing the chemical liquid to form a mixed liquid; b, passing the mixed liquid through a plate heat exchanger Cool down to below 45°C; c. Filter through a bag filter to intercept particles > 5um; d. Send the solution treated by the bag filter to the NF membrane separation system for processing with a high-pressure pump. Obtain high-concentration aluminum waste liquid and acid liquid after aluminum removal purification; e, pump the acid liquid after aluminum removal purification into the evaporation system for evaporation and concentration to recyclable standards.

[0020] The recovery system used for the removal of aluminum from anodized waste liquid includes the first collection pool 1, the second collection pool 2, the third collection pool 3 and the fourth collection pool 4 connected by pipelines, and the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com