Intelligent watering cart and tank body thereof

A sprinkler and tank technology, which is applied in the field of sprinkler, can solve the problem that the residual heat of engine combustion is not fully utilized, and achieve the effect of preventing freezing, melting ice and snow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

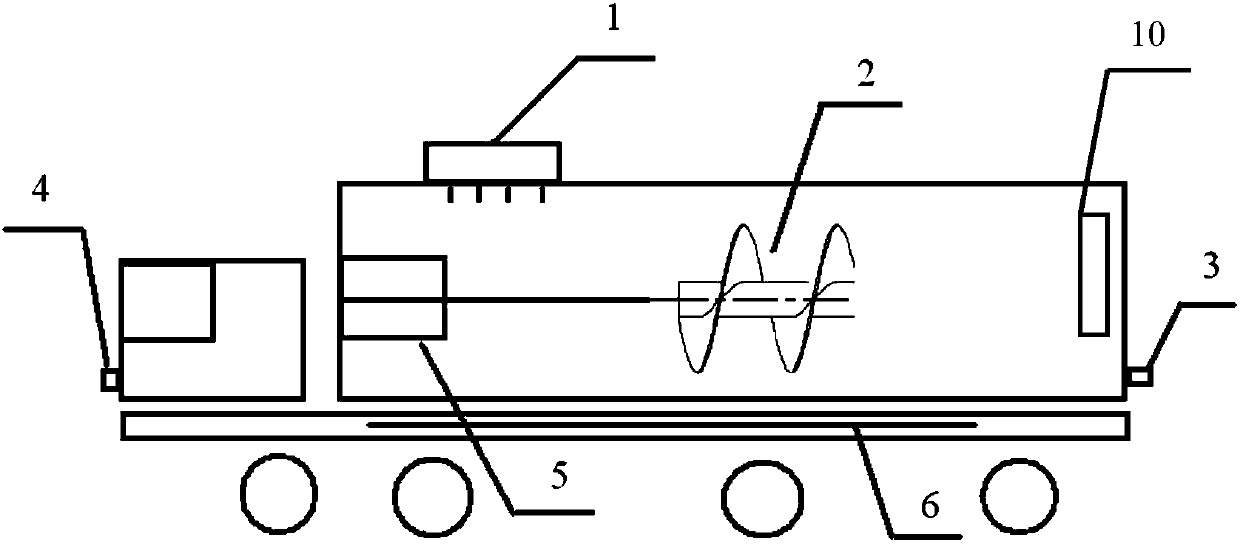

specific Embodiment approach 1

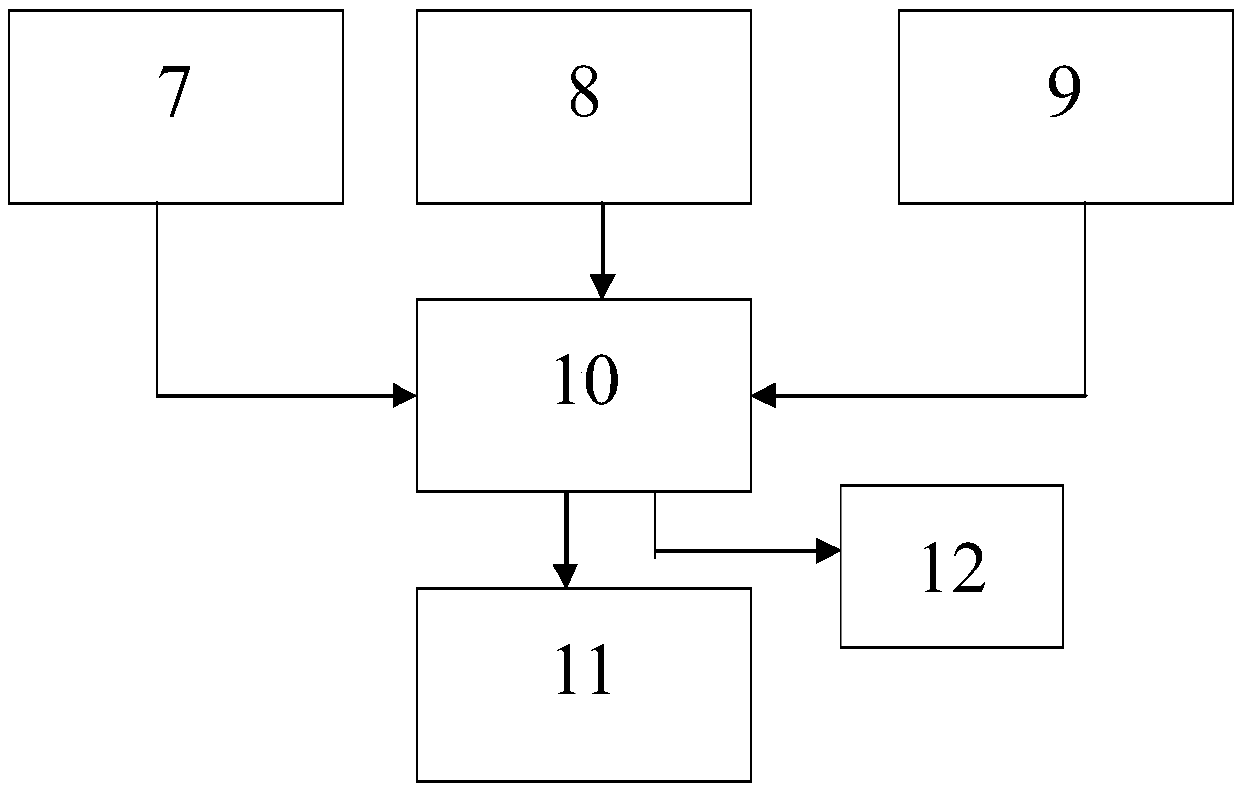

[0026] The working process of this embodiment is as follows:

[0027] (1) After the temperature sensor 7 sends the external ambient temperature signal to the controller 10, if the controller determines that the temperature is below 0 degrees, then it is judged that the water in the fluid pipeline of the sprinkler may freeze, and the pipeline antifreeze mode is started to work— - Drive the controller 11 of the solvent adding device to automatically spray the salt solution into the tank, and drive the power controller 12 to drive the stirring blade 2 to accelerate the dissolving process, and at the same time increase the flow rate of water to slow down the freezing process. This prevents the fluid lines from freezing.

[0028] (2) After the ice and snow information reporting device 8 sends the ice and snow weather information to the controller 10 in real time, the controller judges that the outside is ice and snow weather, and starts the snowmelt mode working state—drives the so...

specific Embodiment approach 2

[0031] The working engineering of this embodiment is basically the same as that of the specific embodiment, and the only difference is that the working mode and control system of the power source 5 of the stirring blade 2 are different from those of the specific embodiment 1.

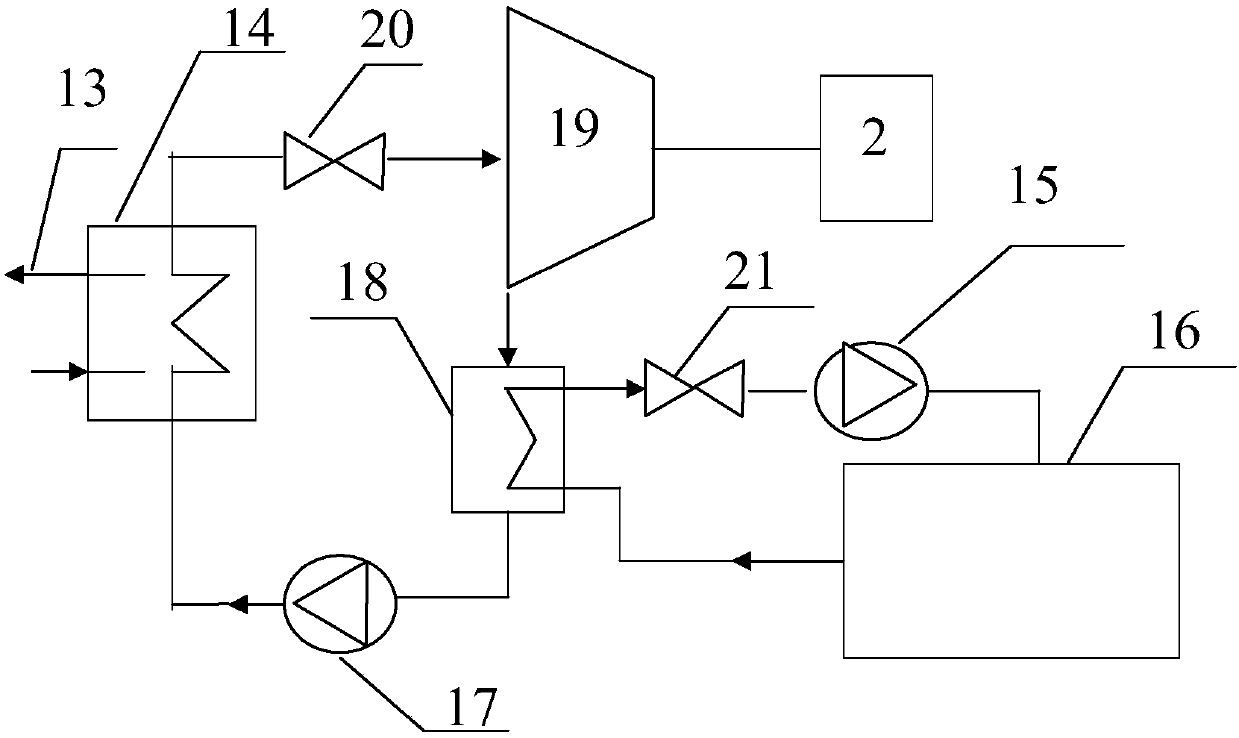

[0032] The specific embodiment 1 is the working type of the power source of the execution part of the usual engineering vehicle, or the power battery is used to directly drive the motor, or the PTO power take-off device is used to take power from the sprinkler engine. Specific embodiment 2 is different from this, it includes engine waste heat power plant, based on the principle of organic Rankine cycle, uses engine waste heat as power to drive stirring blade 2, or as a supplement to conventional power source, provides auxiliary power to drive stirring blade 2 to move , to accelerate the solvent dissolution process.

[0033] The working principle diagram is as follows image 3 As shown, the engine waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com