Hollow shaft type railway vehicle permanent magnetic direct drive traction transmission device

A rail vehicle, permanent magnet direct drive technology, applied to the transmission device driven by the motor, axle box installation, transportation and packaging, etc., can solve the problem of affecting the running performance of the rail vehicle, reducing the output power of the traction motor, and the relatively poor operating road conditions Advanced problems, to achieve the effect of facilitating assembly and post-maintenance, improving overall transmission efficiency, and realizing high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

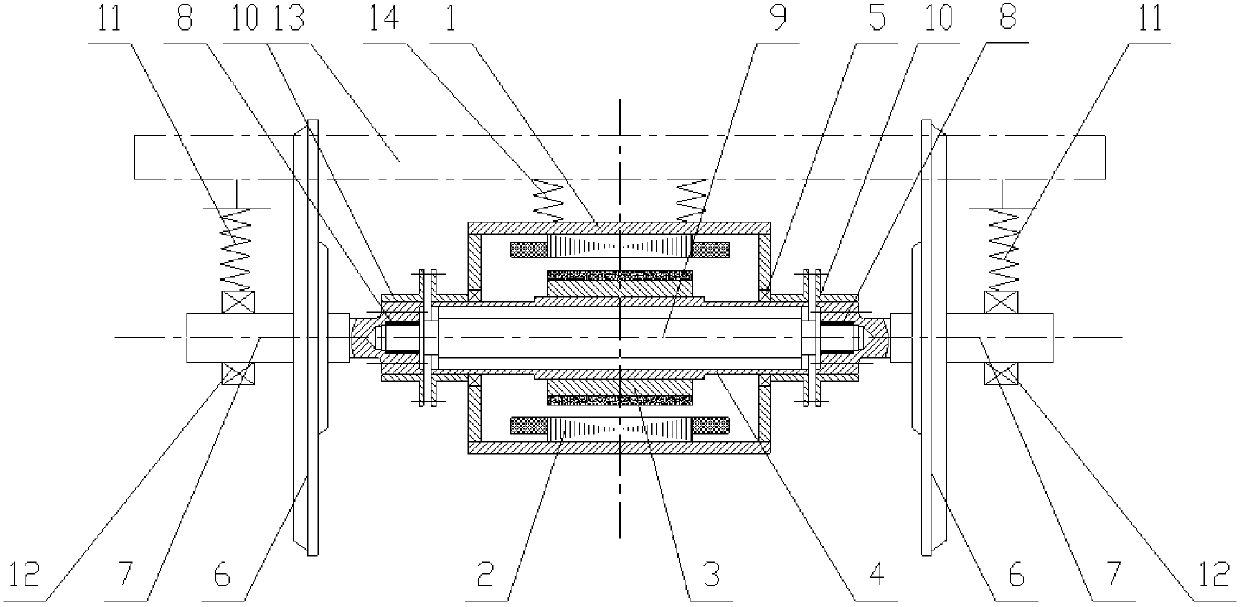

[0022] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the hollow-shaft rail vehicle permanent magnet direct drive traction transmission device includes a permanent magnet traction motor, a connecting shaft 9, a wheel set assembly, an elastic suspension device 14, an elastic coupling 10, an axle box 12, a support spring 11 and Framework 13;

[0023] The permanent magnet traction motor includes a casing 1, a stator 2, a rotor 3 and a power output shaft 4, the stator 2 is pressed inside the casing 1, and the rotor 3 is pressed on the power output shaft 4; the power output shaft 4 It adopts a hollow shaft structure, supported by bearings 5 at both ends, and adopts a double-end simultaneous output structure;

[0024] The wheel set assembly adopts a split structure, including the wheels 6 at both ends, the wheel shaft 7 and the protective bearing 8; the wheel shaft 7 is pressed in the center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com