Polysilazane-zirconium dioxide composite aerogel material as well as preparation method and application thereof

A technology of composite aerogel and polysilazane, which is applied in the production of bulk chemicals, etc., to achieve the effect of simple process, high porosity and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

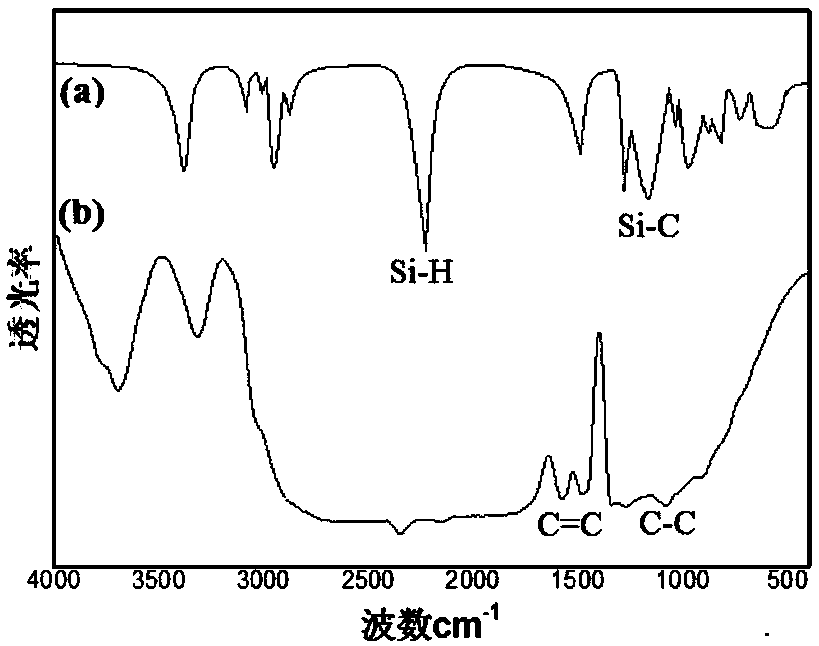

[0032] Step (1) Disperse 0.40g polysilazane (PSN) precursor containing vinyl side chains and Si-H bonds with a number average molecular weight of 1000 in 0.40g toluene, and add 0.05g tetrabutyl zirconate (TBT ) and 0.50g divinylbenzene (DVB), stir rapidly, and then transfer the prepared mixed dilute solution to the polytetrafluoroethylene lining of the hydrothermal reaction kettle, and seal it; the reaction kettle filled with the mixed solution is placed React in a drying oven at 180°C for 3 hours. After cooling to room temperature, a wet gel is obtained. Add toluene into the beaker containing the wet gel to submerge the wet gel test piece, and let it stand for 24 hours before use.

[0033] Step (2) Transfer the product in step (1) to a carbon dioxide supercritical extraction device, immerse in liquid carbon dioxide for about 1 hour, and then perform supercritical drying at a drying temperature and pressure of 45° C. and 8 MPa, respectively, for 6 hours.

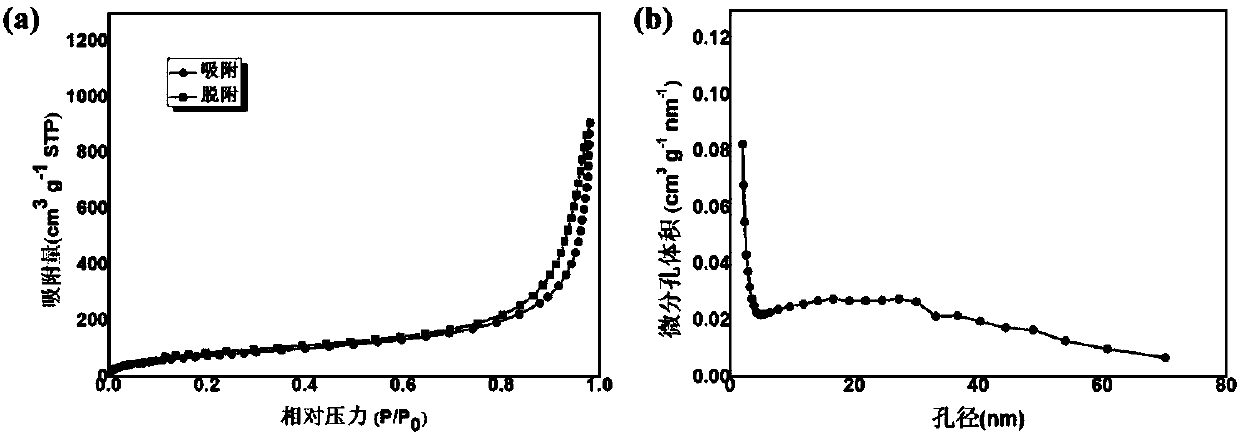

[0034] The specific ...

Embodiment 2

[0036] Step (1) disperse 0.40g polysilazane (PSN) precursor containing vinyl side chains and Si-H bonds with a number average molecular weight of 1000 in 0.40g toluene, and add 0.10g tetrabutyl zirconate (TBT ) and 0.60g divinylbenzene (DVB), stir rapidly, and then transfer the prepared mixed dilute solution to the polytetrafluoroethylene lining of the hydrothermal reaction kettle, and seal it; the reaction kettle filled with the mixed solution is placed React in a drying oven at 160°C for 6 hours. After cooling to room temperature, a wet gel is obtained. Add toluene into the beaker containing the wet gel to submerge the wet gel test piece, and let it stand for 36 hours before use.

[0037] Step (2) The product in step (1) was transferred to a carbon dioxide supercritical extraction device, immersed in liquid carbon dioxide for about 0.5h, and then supercritically dried at a drying temperature and pressure of 40°C and 9MPa for 7h.

[0038] The specific surface area, porosity a...

Embodiment 3

[0040] Step (1) disperse 0.40g polysilazane (PSN) precursor containing vinyl side chain and Si-H bond with number average molecular weight 1000 in 0.40g toluene, add 0.20g tetrabutyl zirconate (TBT ) and 0.80g divinylbenzene (DVB), stir rapidly, then transfer the prepared mixed dilute solution to the polytetrafluoroethylene lining of the hydrothermal reaction kettle, and seal it; the reaction kettle filled with the mixed solution is placed React in a drying oven at 200°C for 1 hour, and cool to room temperature to obtain a wet gel. Add toluene into the beaker containing the wet gel to submerge the wet gel test piece, and let it stand for 32 hours before use.

[0041] Step (2) Transfer the product in step (1) to a carbon dioxide supercritical extraction device, immerse in liquid carbon dioxide for about 2 hours, and then carry out supercritical drying at a drying temperature and pressure of 50° C. and 7 MPa for 8 hours.

[0042] The specific surface area, porosity and density o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com