A kind of pre-embedded adhesive for composite board and preparation method thereof

A composite board and pre-embedded technology, which is applied in the direction of adhesive, adhesive type, epoxy resin glue, etc., can solve the problem of inflexibility of fixed pre-embedded blocks, and achieve excellent high and low temperature resistance, good flame retardancy, excellent anti-corrosion The effect of torsional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A composite board embedded glue and a preparation method thereof, the method comprising the following steps:

[0046] First component preparation method

[0047] (1) Preheat 60kg of 6101 epoxy resin and 12kg of polyurethane modified epoxy resin in the formula, and keep it at 80-100°C for at least 4 hours.

[0048] (2) Put 60kg of 6101 epoxy resin, 12kg of polyurethane modified epoxy resin, and 7.5kg of butyl glycidyl ether into the wall-scraping planetary mixer, start the revolution and disperse stirring, stir and heat to 80-100°C.

[0049] (3) Keep stirring and put 6kg of fumed white carbon black into the mixer gradually and slowly. After the feeding is completed, continue to stir for about 1 hour, and vacuumize for degassing.

[0050](4) Turn off the vacuum, open the feeding port, and keep stirring. Put 1.5kg of reinforcing filler aramid fiber, 30kg of iron powder, 10kg of phosphorus-nitrogen composite flame retardant, and 100kg of flame retardant aluminum hydroxide ...

Embodiment 2

[0064] A kind of high-strength epoxy honeycomb glue and preparation method thereof, the method comprises the following steps:

[0065] First component preparation method

[0066] (1) Preheat 55kg of 618 epoxy resin and 15kg of CTBN modified epoxy resin in the formula, and keep it at 80-100°C for at least 4 hours.

[0067] (2) Put 55kg of 618 epoxy resin, 15kg of polyurethane modified epoxy resin, and 10kg of ethylene glycol bisglycidyl ether required by the formula into the wall-scraping planetary mixer, start the revolution and disperse stirring, stir and heat to 80-100°C.

[0068] (3) Keep stirring and put 8kg of organic bentonite into the mixer gradually and slowly. After the feeding is completed, continue stirring for about 1 hour, and vacuumize for degassing.

[0069] (4) Turn off the vacuum, open the feeding port, and keep stirring. Put 2kg of reinforcing filler aramid fiber powder, 20kg of aluminum powder, 20kg of iron powder, 10kg of phosphorus-nitrogen composite fla...

Embodiment 3

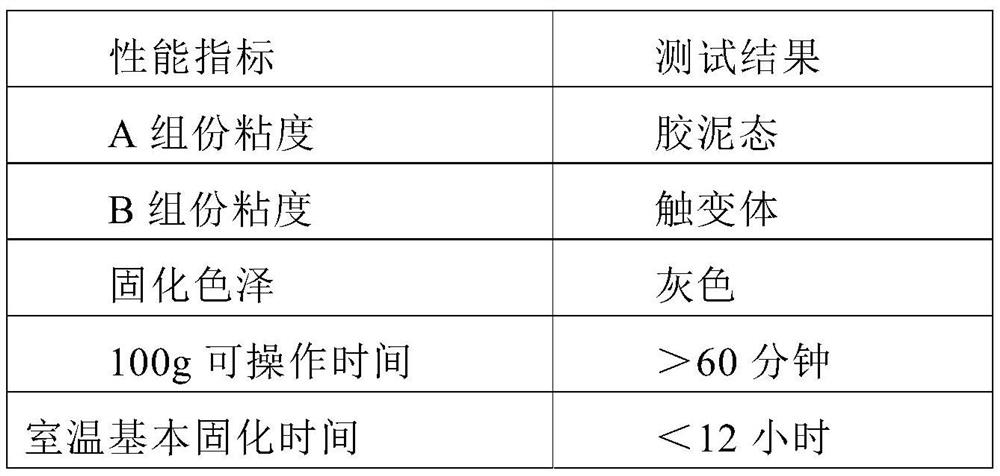

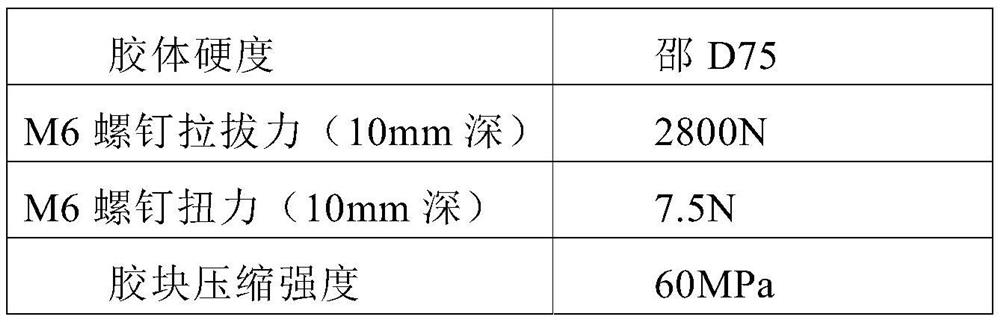

[0082] A kind of pre-embedded glue for composite boards, when used, the first component and the second component are mixed at a weight ratio of 2:1,

[0083] The first component is prepared from the following raw materials in parts by weight: epoxy resin 20, modified epoxy resin 1, reactive diluent 1, reinforcing filler 5, flame retardant 20, thixotropic agent 0.3,

[0084] The second component is prepared by using the following raw materials in parts by weight: toughening curing agent 50, hardening curing agent 10, coupling agent 0.3, thixotropic agent 0.3.

[0085] In the present embodiment, the epoxy resin used is bisphenol A type epoxy resin, the modified epoxy resin is phenolic modified epoxy resin, and the active diluent is ethylene glycol bisglycidyl ether of bisepoxy group, supplemented The strong filler is calcium sulfate whisker, the flame retardant is magnesium hydroxide, and the thixotropic agent is organic bentonite. The toughening and curing agent is aromatic po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com