Metal surface defect image recognition non-destructive testing device and method

A metal surface, non-destructive testing technology, used in measuring devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve problems such as easy missed inspection, high condition requirements, and unsuitable for large-area or large-scale equipment testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

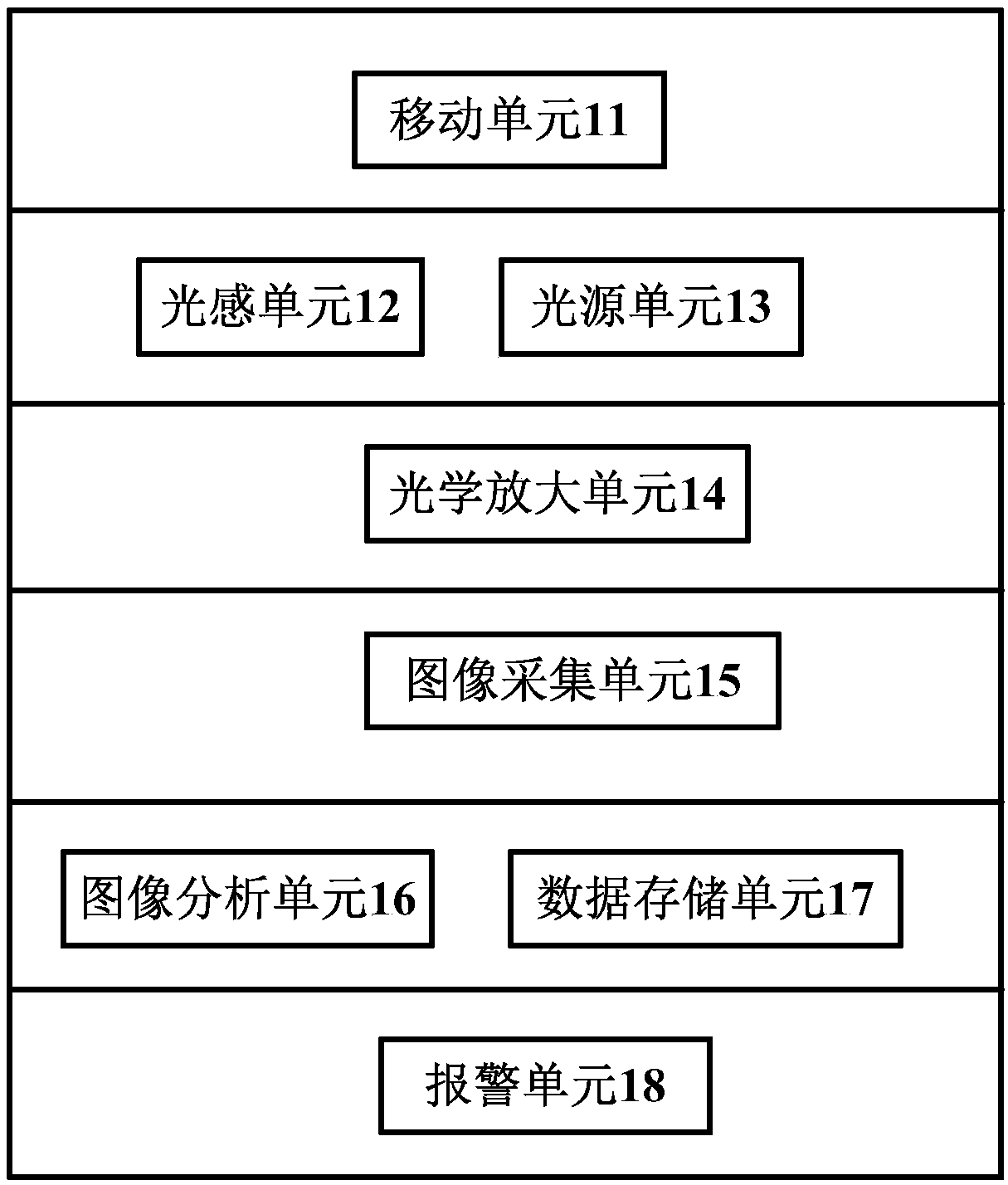

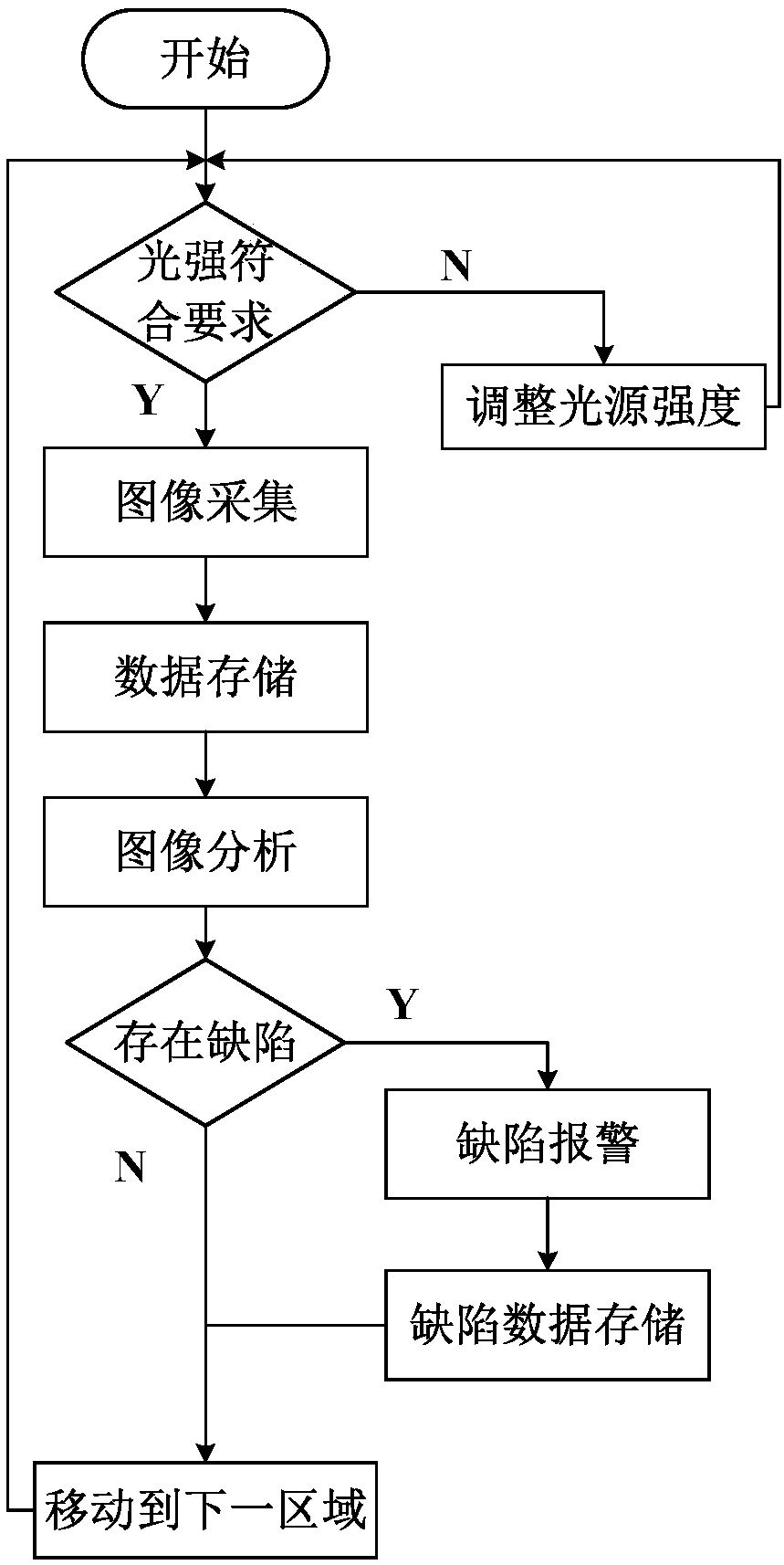

[0091] see figure 1 As shown, the embodiment of the present invention provides a non-destructive testing device for image recognition of metal surface defects, including a moving unit 11, a photosensitive unit 12, a light source unit 13, an optical amplification unit 14, an image acquisition unit 15, an image analysis unit 16, data Storage unit 17, alarm unit 18.

[0092] The mobile unit 11 is equipped with a light sensing unit 12, a light source unit 13, an optical amplification unit 14, an image acquisition unit 15, an image analysis unit 16, a data storage unit 17, and an alarm unit 18. The light sensing unit 12 is connected with the light source unit 13, and the optical amplification Unit 14 links to each other with image acquisition unit 15, and image acquisition unit 15 connects image analysis unit 16, data storage unit 17 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com