Integrated device used for fixed-size cutting of high-precision pipe

A high-precision, pipe material technology, applied in the direction of shearing machine equipment, metal processing equipment, pipe shearing device, etc., can solve the problems of unfavorable batch production, limited processing capacity, pinch and bruise, etc., and achieve the reduction of operation level and experience, Novel and reasonable design, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

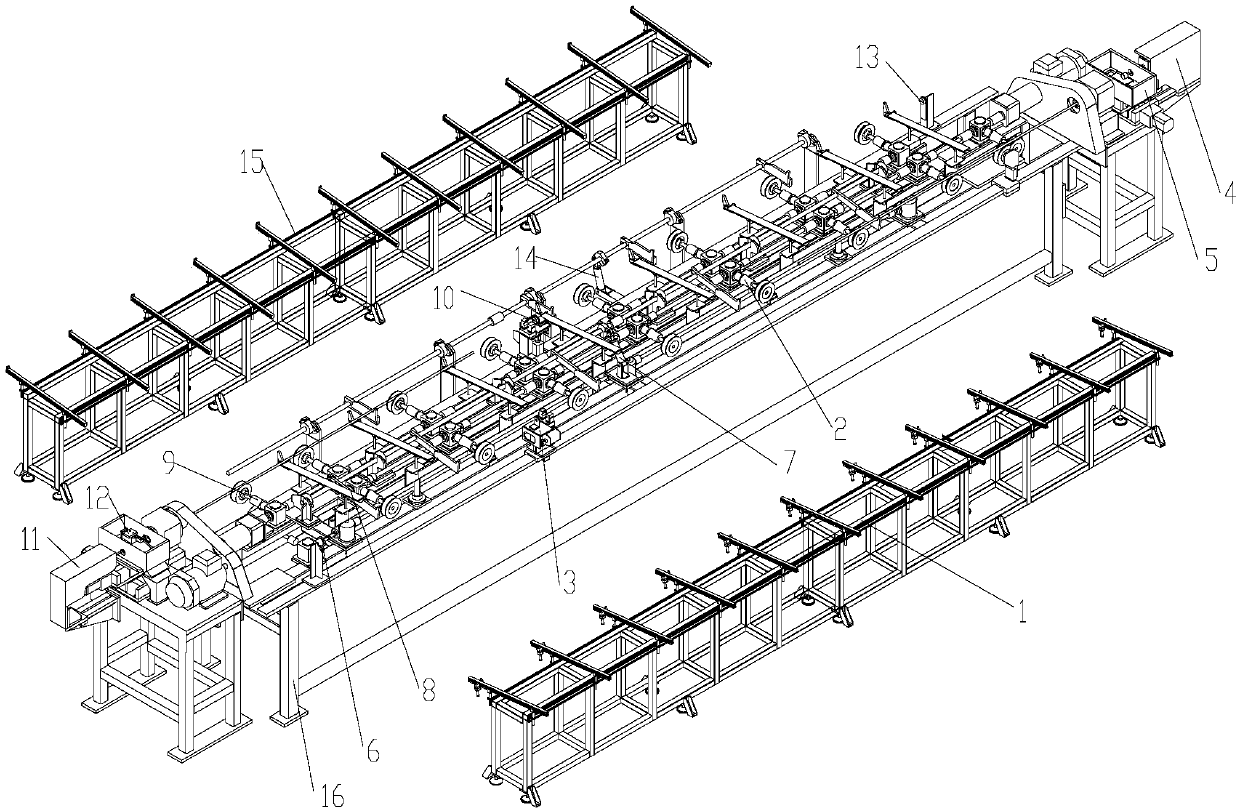

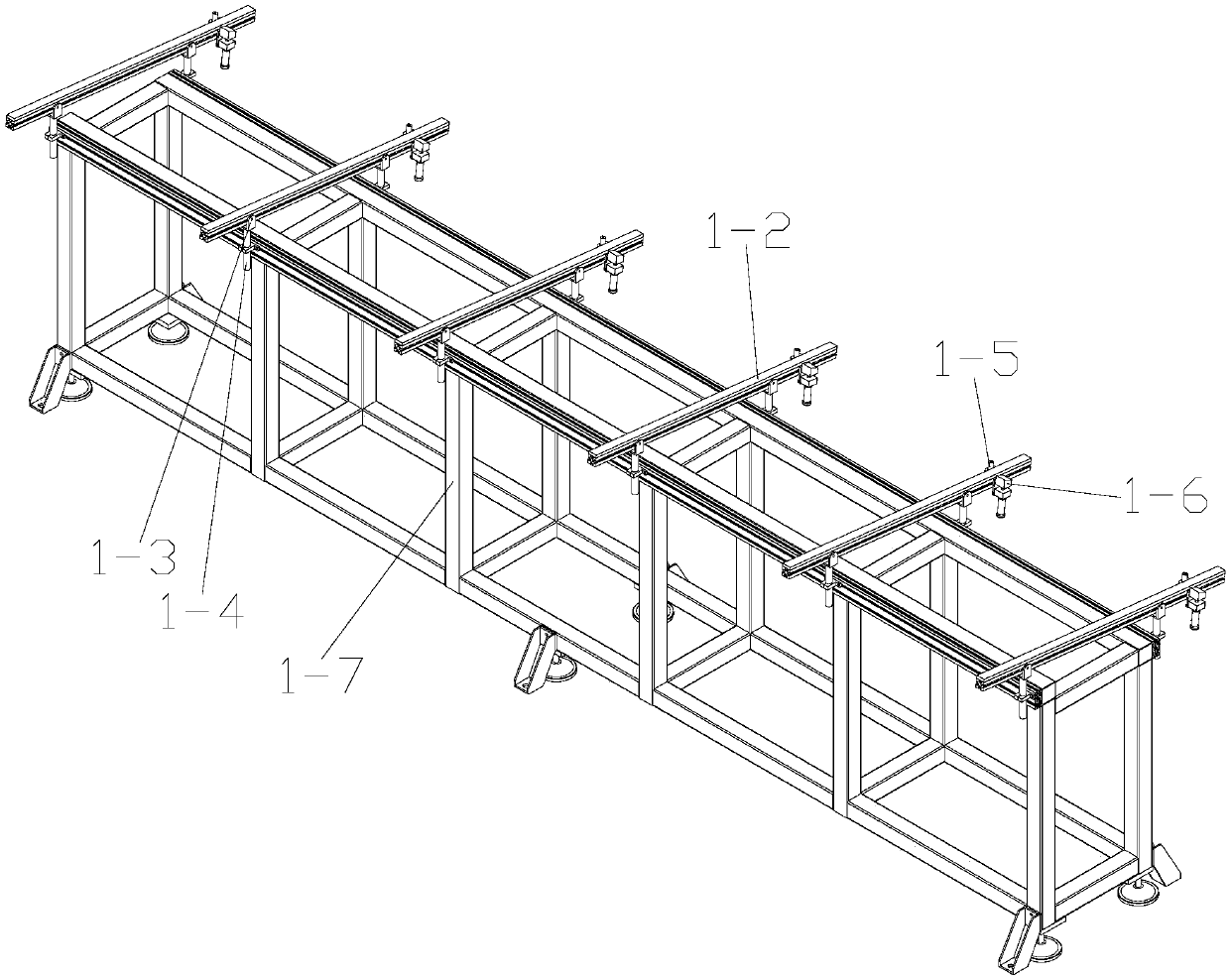

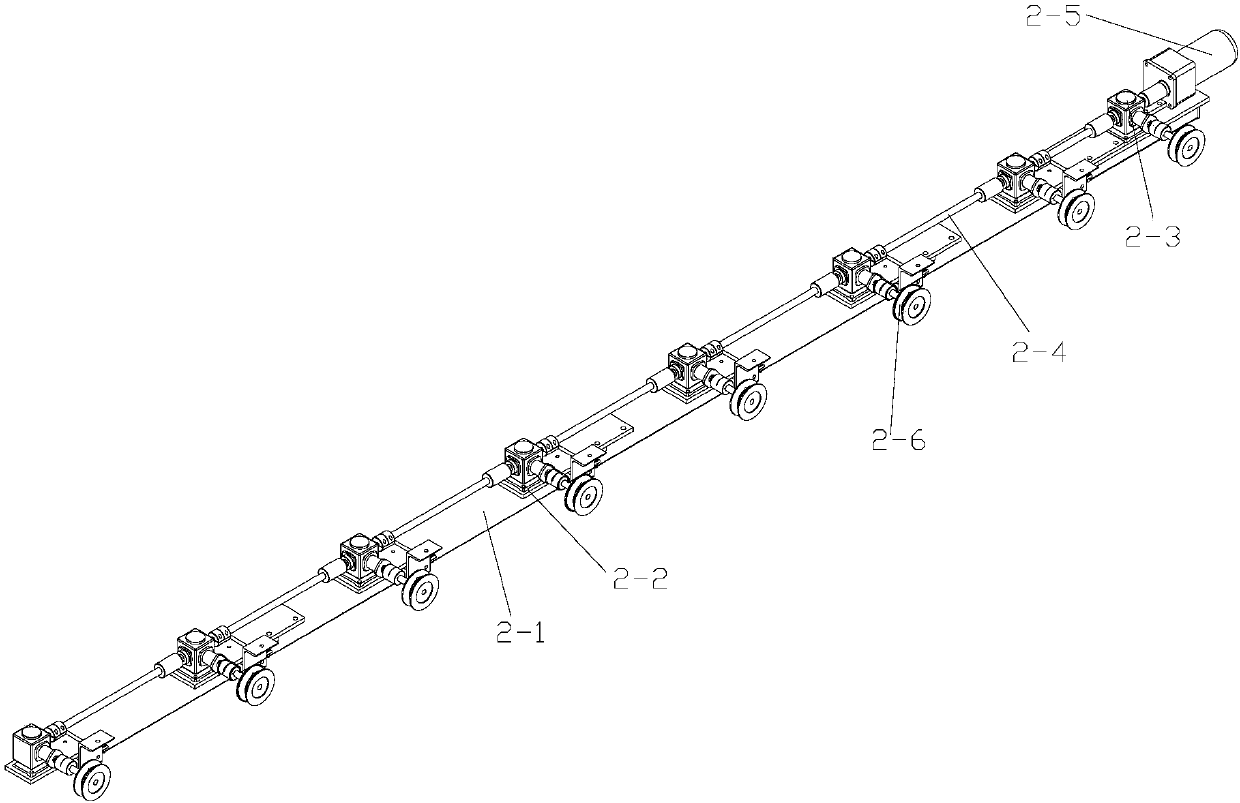

[0062] Such as figure 1 As shown, the present invention includes a pipe material feeding device 1, a processing platform and a pipe material unloading device 15. The processing platform includes a support 16 and a first processing device that is installed on the support 16 for cutting off one end of the pipe to be processed. , a transition device for transferring the pipe material processed by the first processing device, a second processing device for cutting the other end of the pipe material to be processed to length, and a pipe material processed by the second processing device The overturning device 14 that performs overturning, the overturning device 14 cooperates with the pipe material unloading device 15; the first processing device and the second processing device have the same structure, and the first processing device includes a pipe material feeding device 1 that cooperates and is used for conveying The first transmission mechanism 2 for the pipe to be processed, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com