Cabin section and machining method thereof

A processing method and cabin technology, applied in the cabin and its processing field, can solve the problems of high cost and complicated welding process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

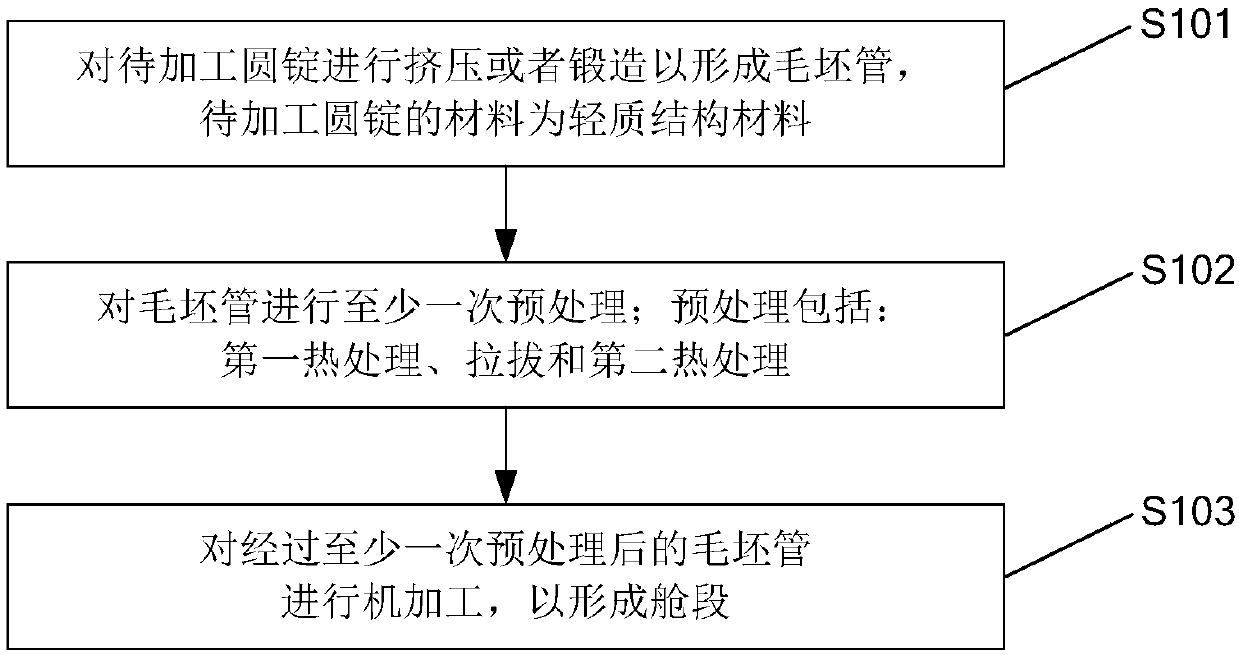

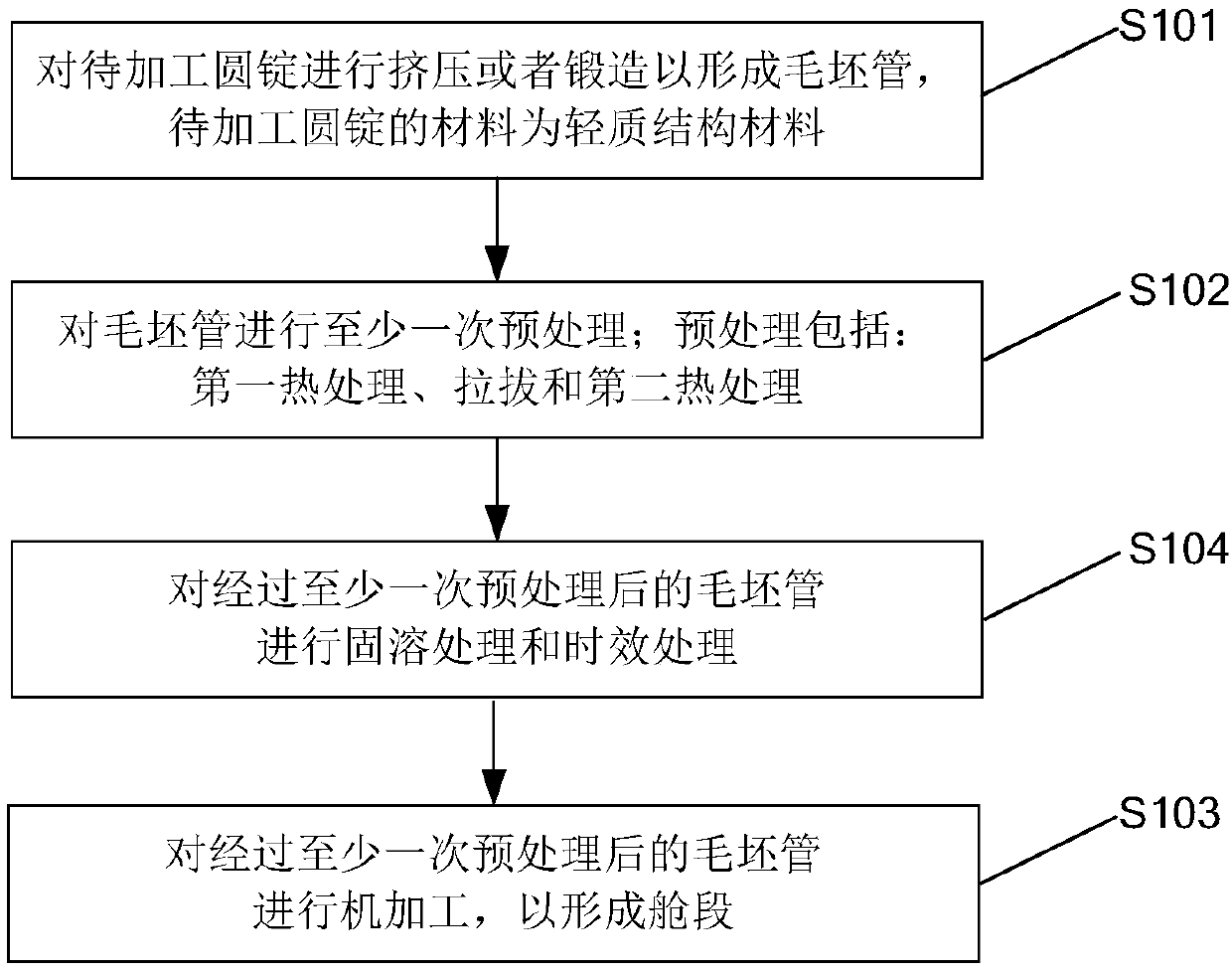

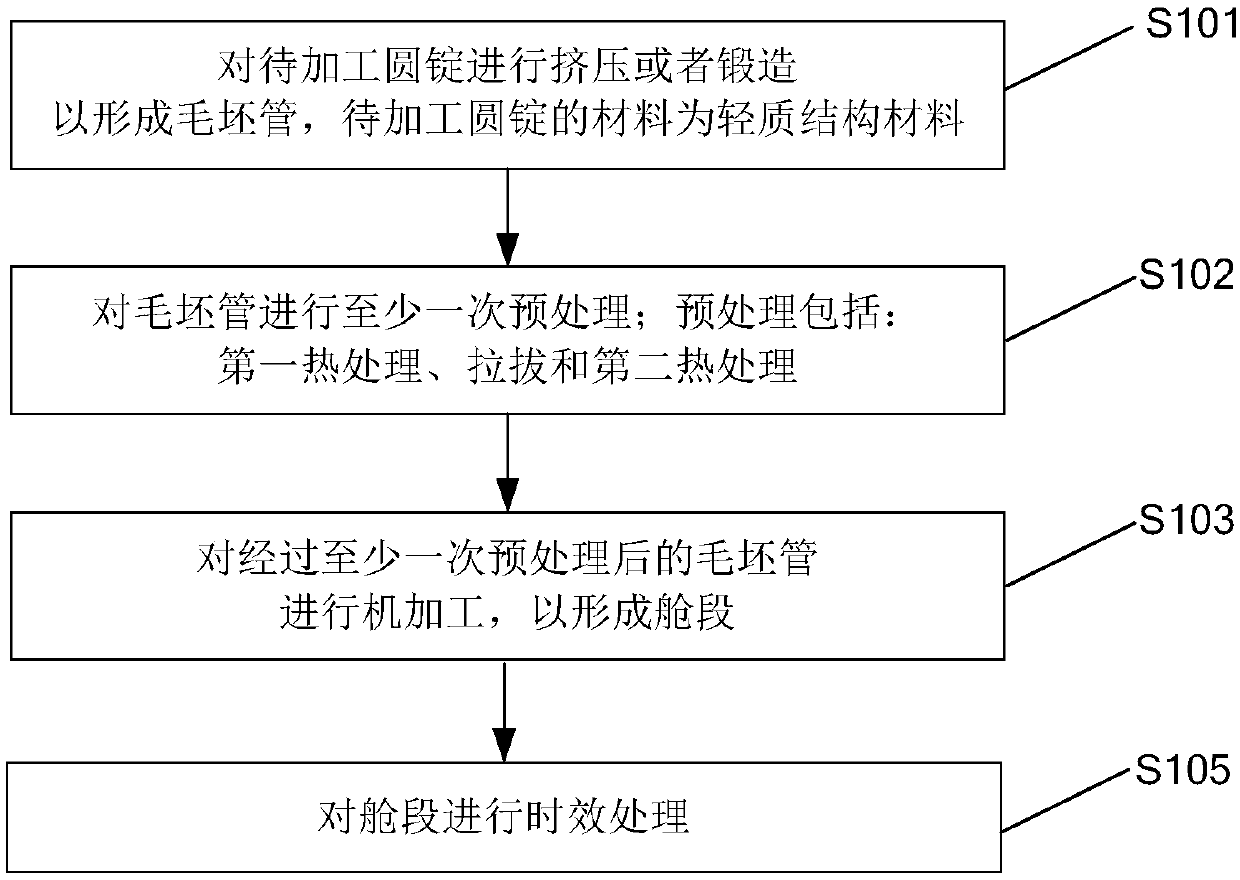

[0024] Embodiments of the present invention provide a cabin processing method, refer to figure 1 As shown, the method includes:

[0025] S101. Extrude or forge the round ingot to be processed to form a blank tube, and the material of the round ingot to be processed is a lightweight structural material.

[0026] The specific method for forming the round ingot to be processed is not limited here, and it can be made by die casting or continuous casting. In order to ensure the quality of the round ingot to be processed, the latter is preferred. That is, the round ingot to be processed is preferably a continuous casting round ingot. In addition, there is no limitation on the diameter of the round ingot to be processed, which can be selected according to actual needs.

[0027] Here, there is no limitation on the specific type of lightweight structural material, which may be aluminum alloy, magnesium alloy, titanium alloy or metal matrix composite material.

[0028] S102. Perform ...

Embodiment 2

[0049]An embodiment of the present invention provides a cabin section, and the cabin section is manufactured by any one of the processing methods provided in the first embodiment. This cabin section can be applied to spaceships and missiles, and is an important component. The compartment is characterized by low cost and high quality. At the same time, the cabin section is made of lightweight structural materials, which also has the characteristics of light weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com