Micro-fiber leather hot vulcanizing adhesive for rubber shoes as well as preparation method and use method thereof

A microfiber leather and adhesive technology, applied in the field of rubber processing, can solve problems such as failure to meet performance requirements and failure to achieve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

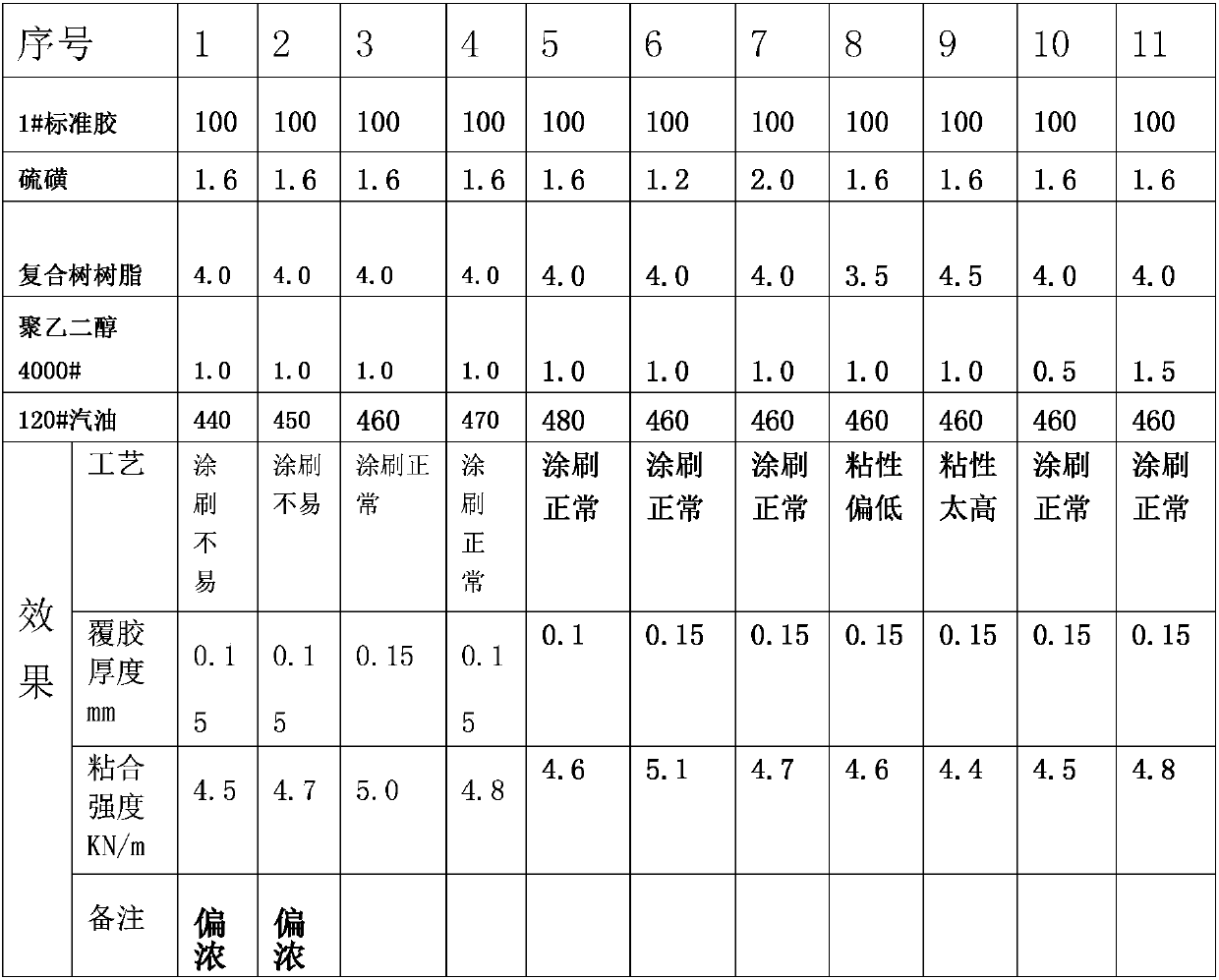

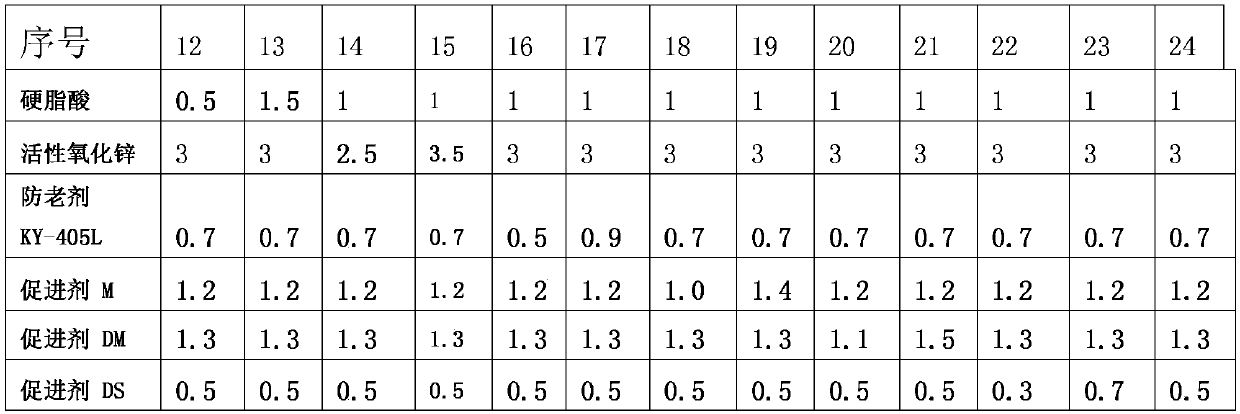

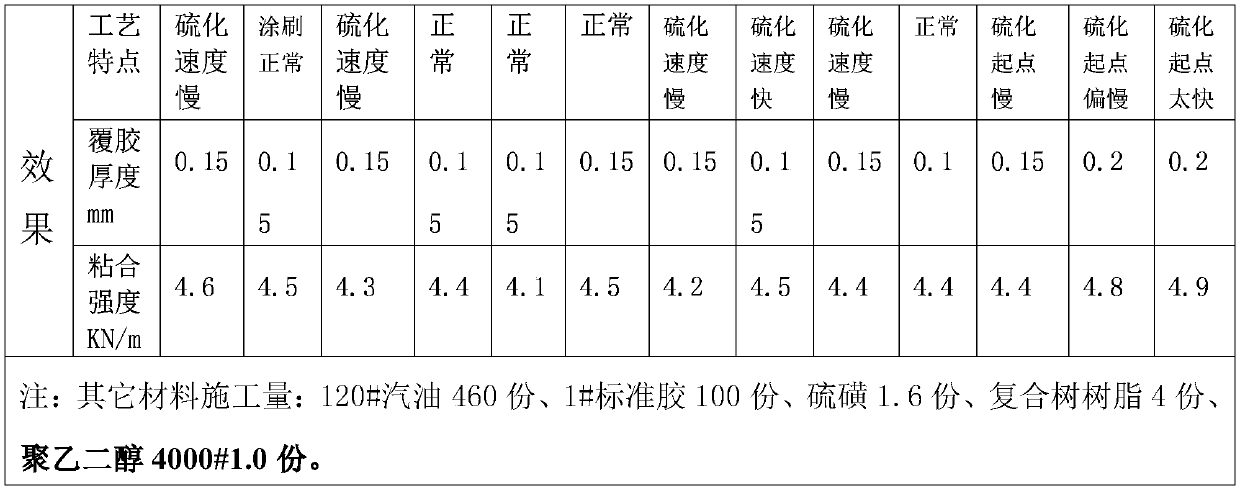

[0073] Embodiment 1 of the present invention: microfiber leather thermal vulcanization adhesive for rubber shoes, including microfiber leather graft treatment agent, bonding transition agent, adhesive and rubber surface treatment agent; calculated by mass parts, microfiber leather The composition of the graft treatment agent includes 8 parts of curing agent E766 and 92 parts of shoe upper treatment agent P-206F; the composition of the adhesive transition agent includes 8 parts of curing agent E766 and 92 parts of treatment agent Na-036; the adhesive is adhesive Na047; The composition of the rubber surface treatment agent includes 100 parts of 1# standard rubber, 1.6 parts of sulfur, 4 parts of composite tree resin, 3 parts of vulcanization accelerator, 4 parts of vulcanization activator, 1 part of polyethylene glycol 4000#, antioxidant K 0.7 parts of -405L and 460 parts of 120# gasoline; every 3 parts of vulcanization accelerator is composed of 1.2 parts of accelerator M, 1.3 p...

Embodiment 2

[0094] Embodiment 2 of the present invention: microfiber leather thermal vulcanization adhesive for rubber shoes, including microfiber leather graft treatment agent, bonding transition agent, adhesive and rubber surface treatment agent; Calculated by mass parts, microfiber leather The composition of the graft treatment agent includes 8 parts of curing agent E766 and 92 parts of shoe upper treatment agent P-206F; the composition of the adhesive transition agent includes 8 parts of curing agent E766 and 92 parts of treatment agent Na-036; the adhesive is adhesive Na047; The composition of the rubber surface treatment agent includes 100 parts of 1# standard rubber, 1.8 parts of sulfur, 4 parts of composite tree resin, 2.8 parts of vulcanization accelerator, 4.2 parts of vulcanization activator, 1 part of polyethylene glycol 4000#, antioxidant K 0.8 parts of -405L and 465 parts of 120# gasoline; every 3 parts of vulcanization accelerator is composed of 1.2 parts of accelerator M, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com