Static inclination test bench control system

A technology of control system and tilt test, which is applied in the field of machinery, can solve problems such as complex control, and achieve the effects of meeting robustness requirements, reducing electromagnetic noise, and improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

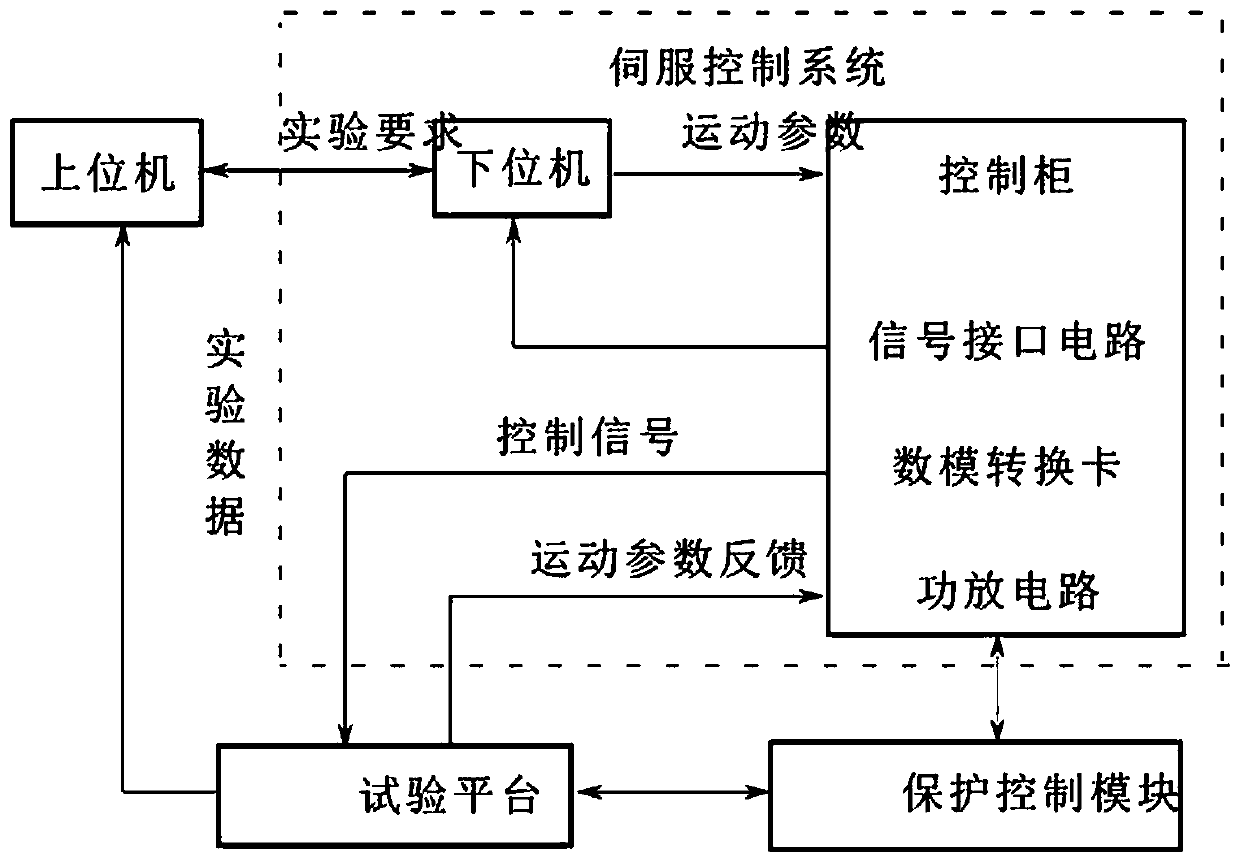

[0014] Such as figure 1 , The control system of the tilting test bench consists of two parts: mechanical and electrical control. Considering the volume and weight of the load, the mechanical part uses the hydraulic cylinder as the main driving device.

[0015] The electrical control part includes upper computer, lower computer, protection control circuit, data acquisition unit, etc.

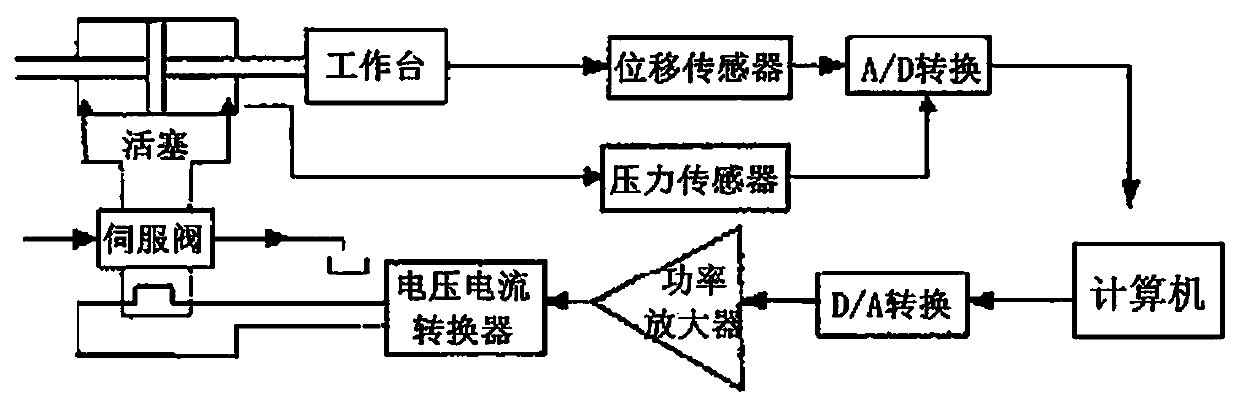

[0016] To design a control system, we must first consider the input signal of the system, that is, the final control quantity of the system. For a tilting test bench system, the input signal is the tilt angle of the bench top. However, the actual physical system is a mechanical structure of seven linkages, and the platform structure is composed of a platform, a foundation, a hydraulic cylinder, tie rods and a spherical joint. The hydraulic cylinder is connected between the upper platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com