On-line monitoring method of gas heating value and boiler thermal efficiency of blast furnace gas boiler

A boiler thermal efficiency, blast furnace gas technology, applied in the direction of measuring devices, fuel oil testing, material thermal development, etc., can solve the problems of difficult to maintain stability of blast furnace gas composition and calorific value, affecting the solution of boiler thermal efficiency, and deviation of regular test values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

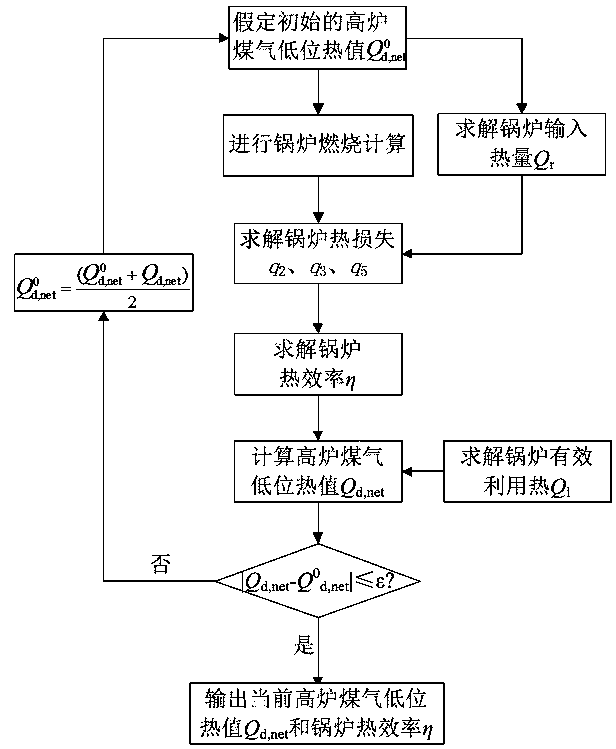

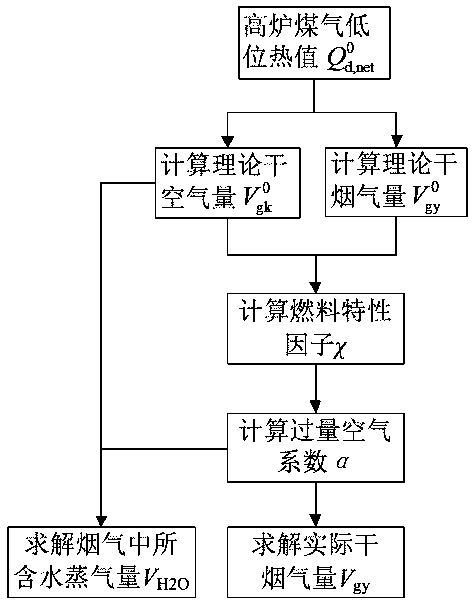

[0092] The present invention will now be described in further detail with reference to the accompanying drawings.

[0093] like figure 1 , figure 2 The shown on-line monitoring method of the calorific value of the blast furnace gas boiler entering the furnace gas and the thermal efficiency of the boiler, the realization scheme is as follows:

[0094] 1. Collect the online operation data of the unit in real time through the factory-level monitoring information system, including: oxygen content in flue gas, CO content in flue gas, exhaust gas temperature, blast furnace gas flow into the furnace, boiler evaporation, ambient temperature, and boiler efficiency Use thermal input parameters.

[0095] 2. Perform preprocessing on the input data obtained in step 1, including dead pixel processing and data smoothing processing, to obtain valid data for calculating the calorific value of blast furnace gas and boiler thermal efficiency.

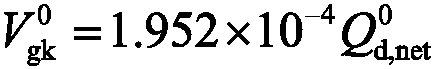

[0096] 3. Obtain the calorific value of the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com