Hot-rolled strip steel MES parallel debugging data collection method

A technology for data acquisition and hot-rolled strip steel, which is applied in the field of parallel debugging data acquisition of hot-rolled strip steel MES system, can solve problems such as adverse effects, low system operation performance, and high equipment failure rate, so as to improve work efficiency and achieve considerable social benefits , improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

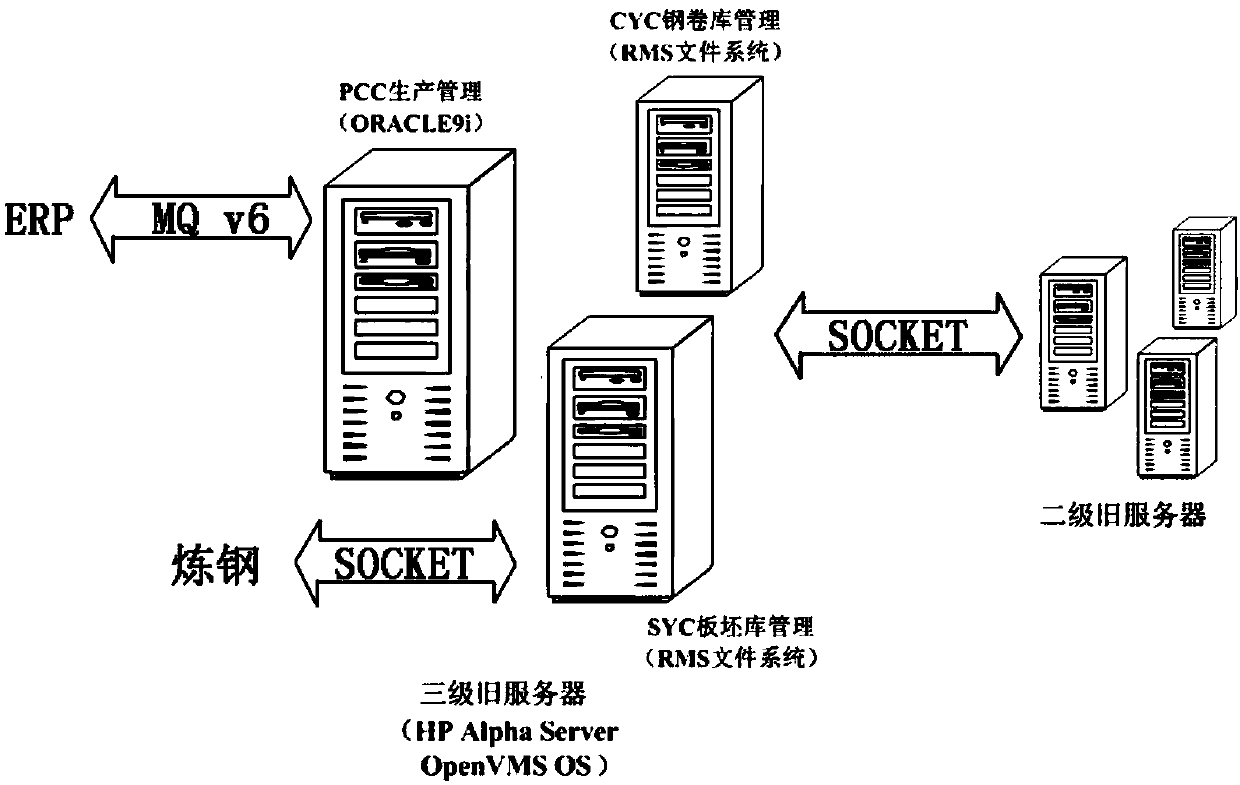

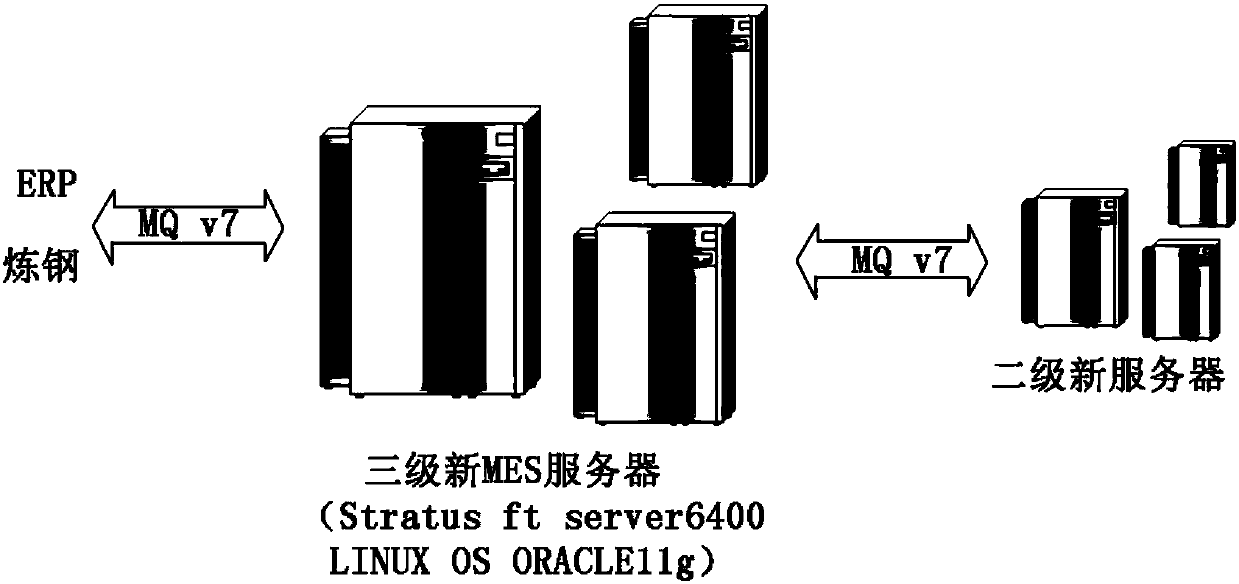

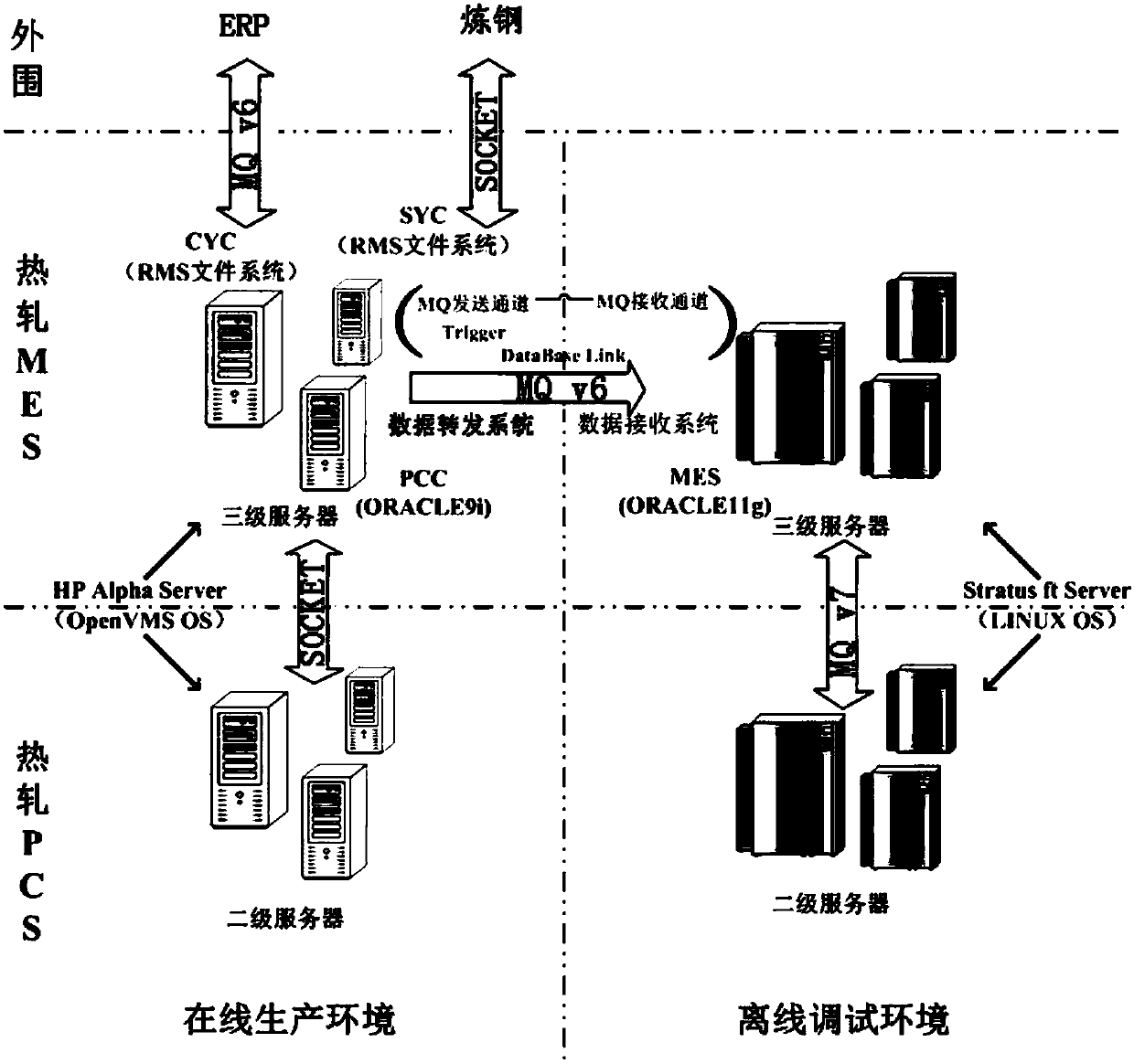

[0029] Stratus ft server 6400 series servers are used as the new third-level MES system and the new second-level PCS system, all of which run the LINUX operating system, use the ORACLE11g database to store data, and use MQ middleware to realize the new second-third-level system and third-level-ERP enterprise Resource planning system and Level 3 - MES systems for steelmaking. During the transformation period, the new third-level MES system and the new second-level PCS system run offline, responsible for development and debugging tasks, see figure 2 .

[0030] The debugging work must be synchronized with the production, and cannot affect the production activities of the enterprise, and it is necessary to ensure that the data of the second and third level new system debugging is accurate and effective, which requires that the third level MES system must provide all the data required for online production in real time during the debugging process. , starting from our own situati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com