A kind of electrolytic capacitor aging method

A technology of electrolytic capacitors and electrolytes, applied in the direction of electrolytic capacitors, electrolytic capacitor manufacturing, liquid electrolytic capacitors, etc., can solve the problems of capacitors that cannot be aged in sections, capacitor power instability, capacitor performance instability, etc., to achieve low loss and pass rate High, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

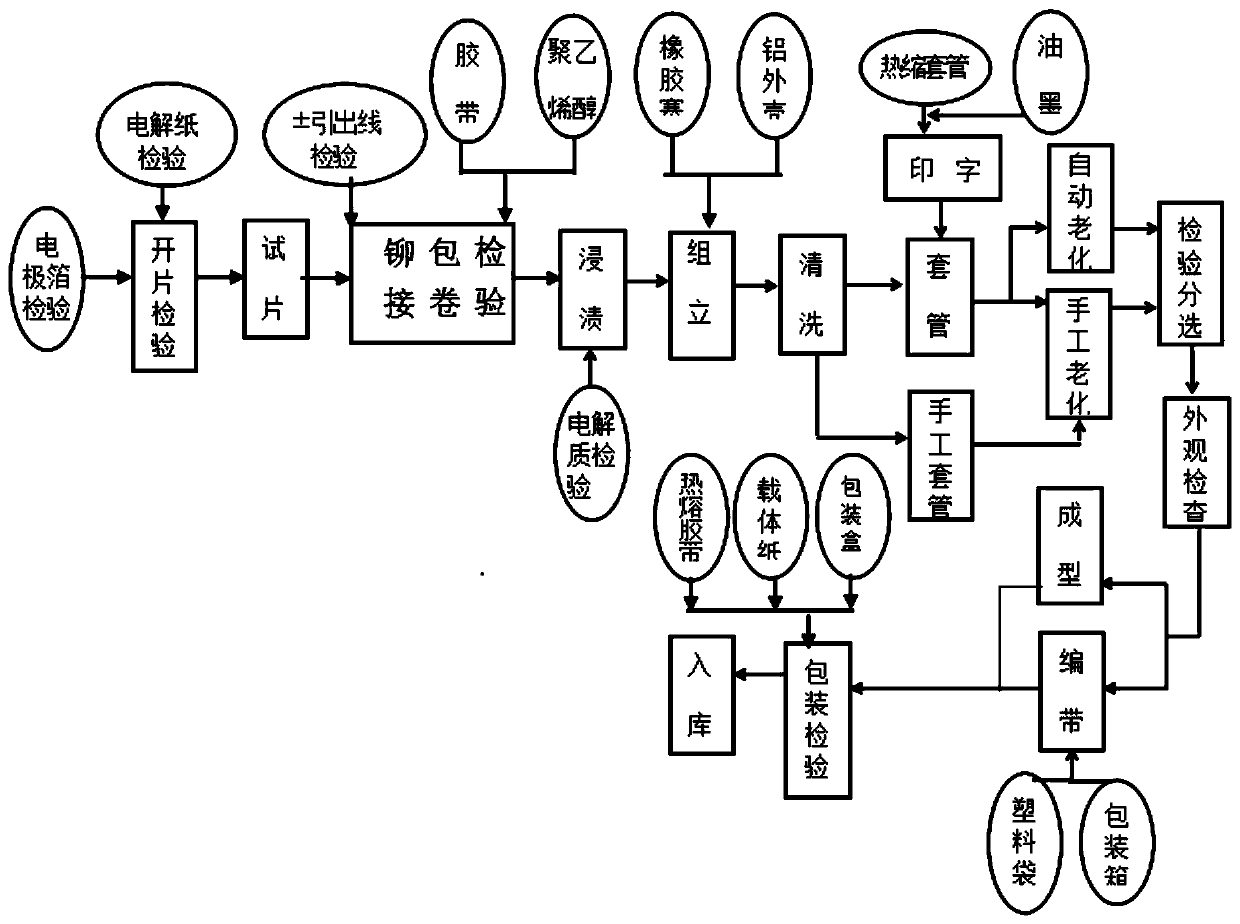

[0036] Such as figure 1 Shown, a kind of electrolytic capacitor aging method, its aging method step is as follows:

[0037] Step A, preparation of materials, inspection of electrode foil, electrolytic paper, ± lead wire, tape, polyvinyl alcohol, rubber plug, aluminum shell, heat shrinkable sleeve, ink, electrolyte, hot melt tape, carrier paper, packaging box, plastic Whether the bags and boxes are qualified;

[0038] Step B. The electrode foil and electrolytic paper that pass the inspection in step A are subjected to sheet inspection, and the semi-finished products that pass the inspection are subjected to test sheet operation;

[0039] Step C, riveting and wrapping the lead wires, adhesive tape, polyvinyl alcohol prepared in step A and the semi-finished product after the test piece in step B to make a core bag and checking whether it is qualified;

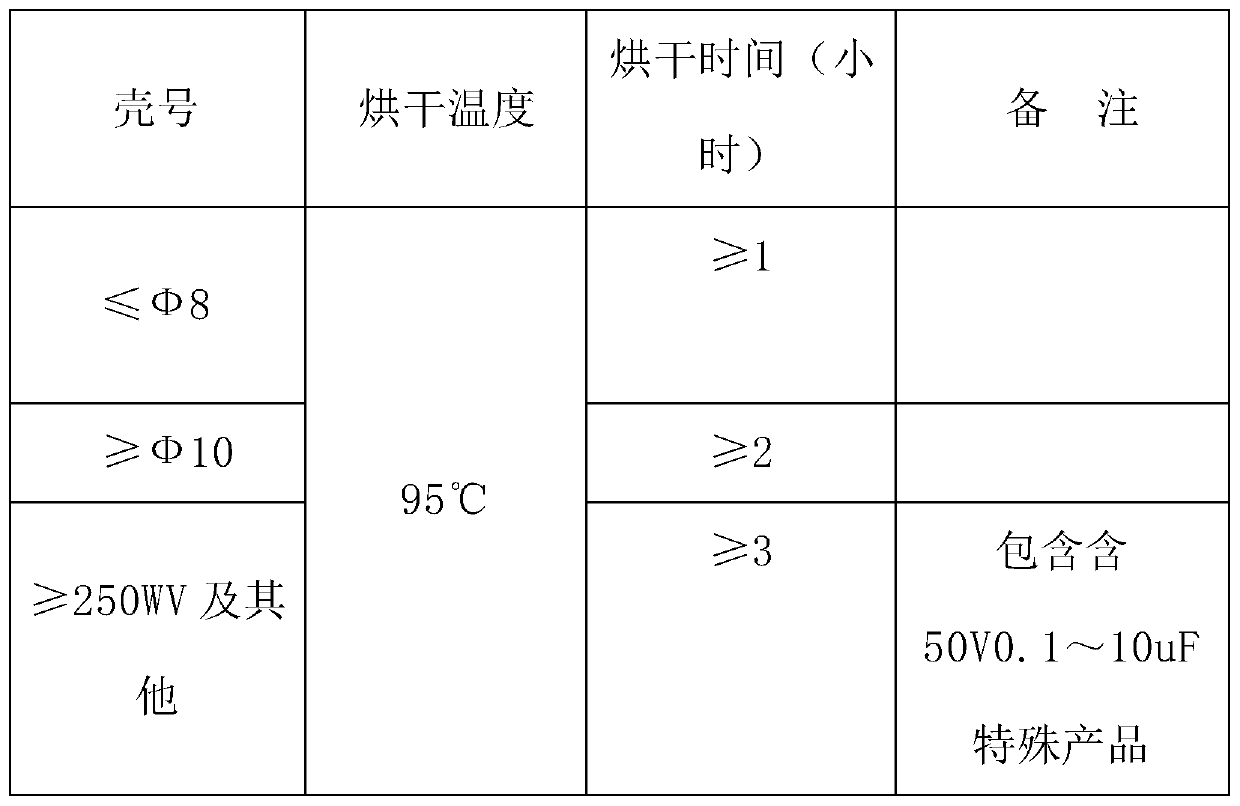

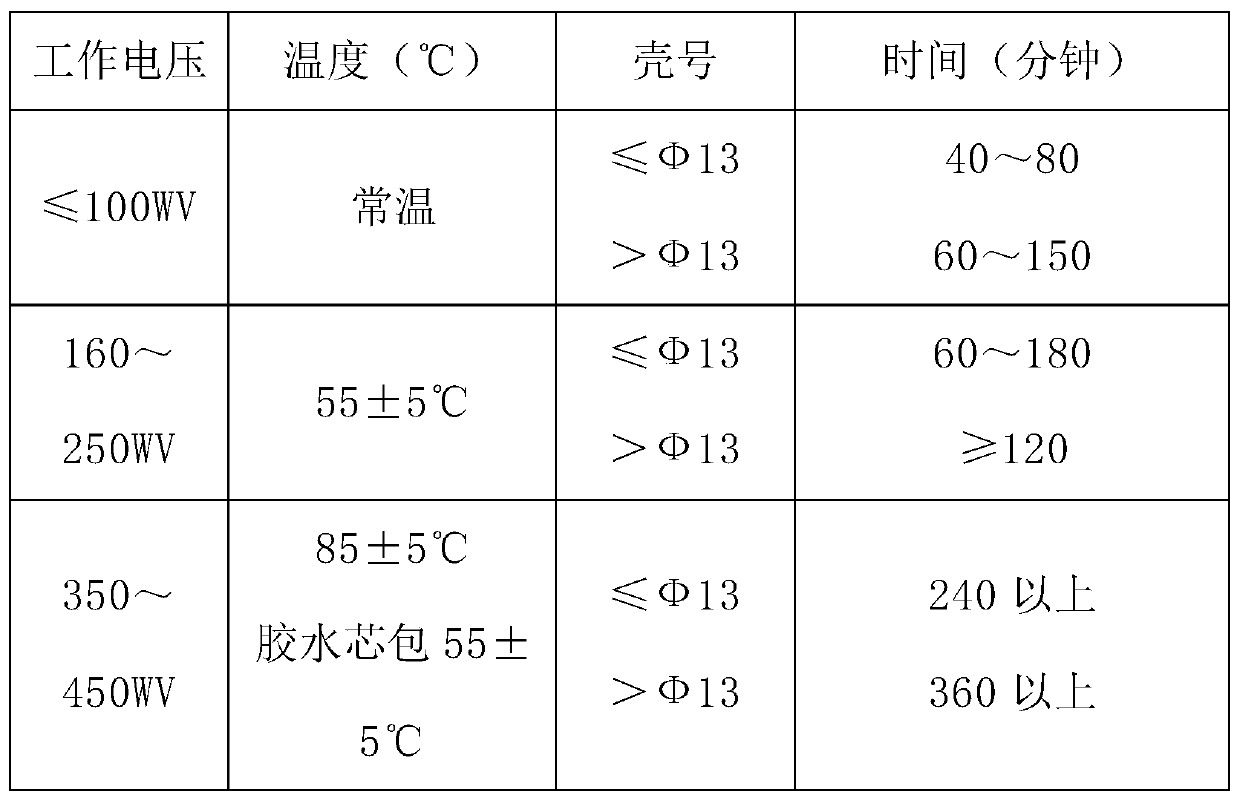

[0040]Step D, impregnate the qualified core package in step C, put the core package to be soaked into a baking tray and put it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com