Photoelectric detecting structure and preparation method thereof

A photodetection, photodiode technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of low photoresponsivity, the influence of visible light divergent image quality, etc., to achieve high photoresponsivity, good image clarity, reduce light the divergent effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

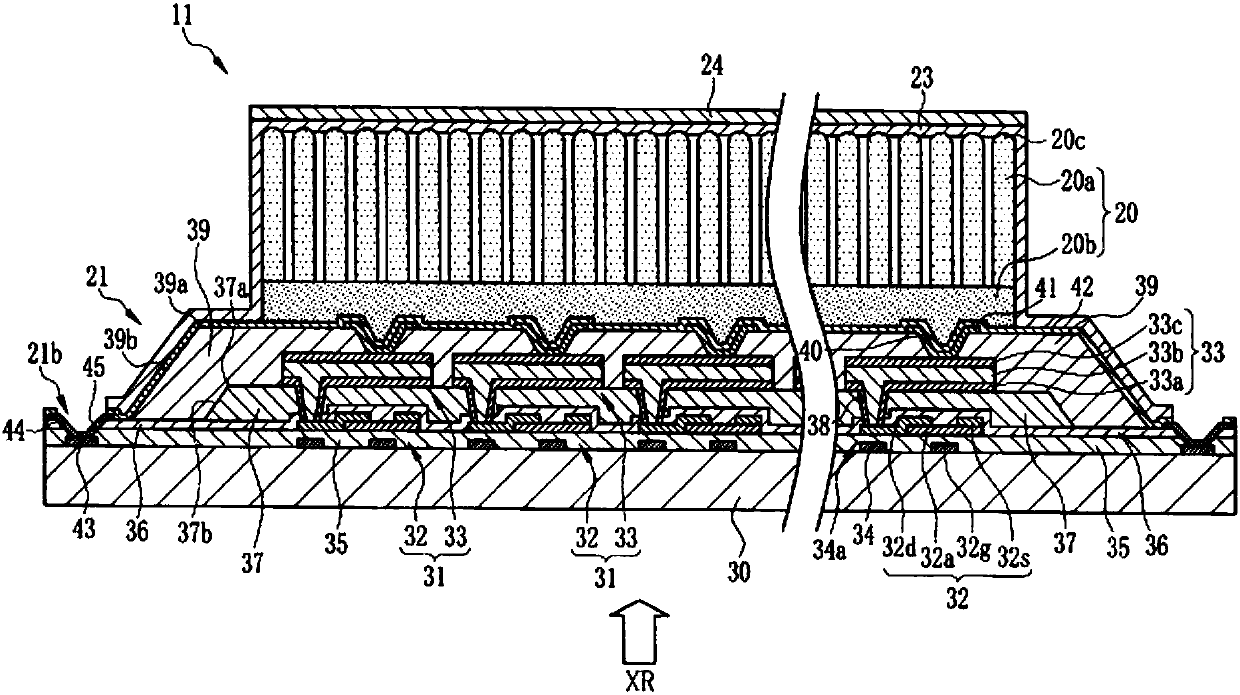

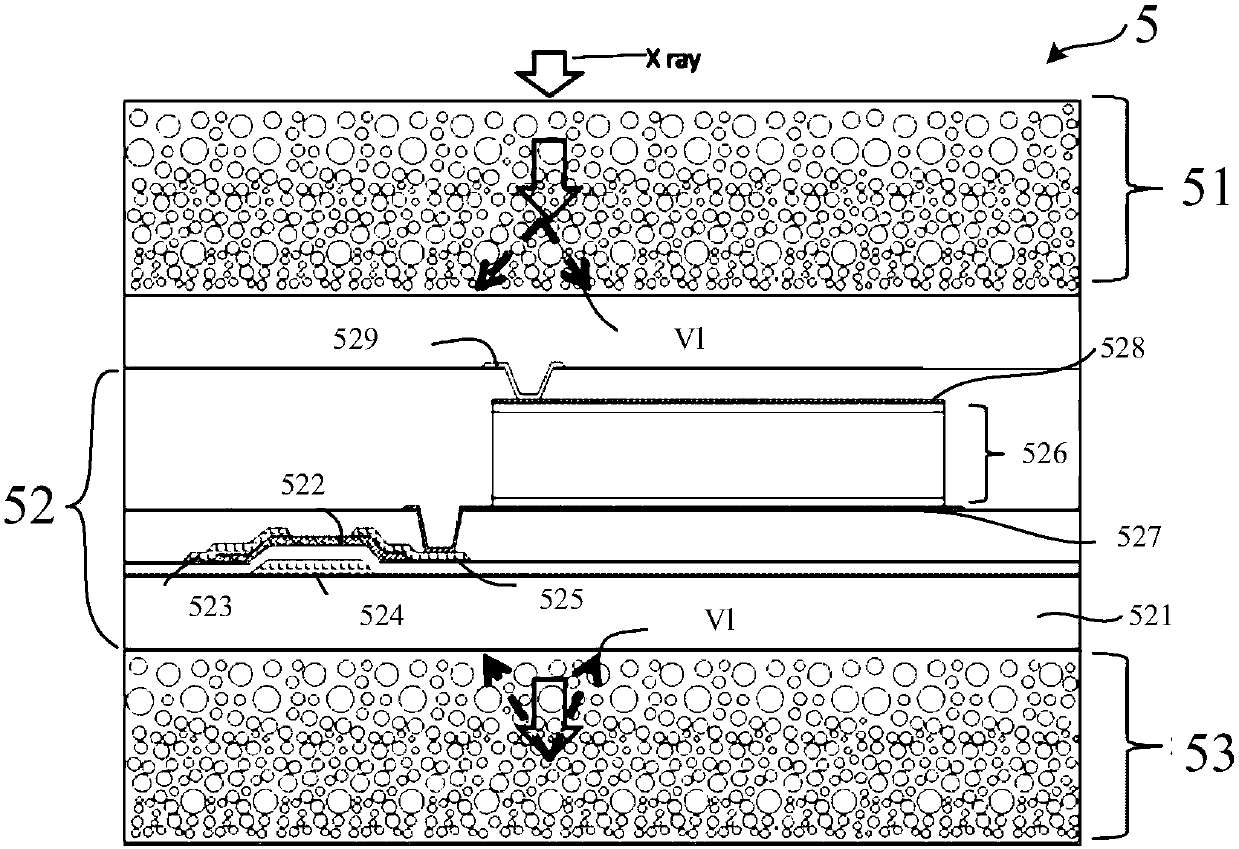

[0047] Such as image 3 As shown, the present invention provides a kind of photodetection structure 5, and described photodetection structure 5 comprises at least:

[0048] The first scintillator layer 51 , the first visible light sensor 52 , and the second scintillator layer 53 .

[0049] Such as image 3 As shown, the first scintillator layer 51 is located on the X-ray (X ray) receiving surface of the photodetection structure 5, and is used to absorb X-rays with lower energy and convert X-rays into visible light V1, and visible light V1 is obtained from The output from the first scintillator layer 51 is detected by the first visible light sensor 52 .

[0050] Specifically, the material of the first scintillator layer 51 includes but not limited to cesium iodide or gadolinium oxysulfide, and any material that can convert X-rays into visible light is suitable for the present invention, not limited to this embodiment.

[0051] Such as image 3 As shown, the second scintilla...

Embodiment 2

[0060] This embodiment provides a photoelectric detection structure, which is basically the same as that of Embodiment 1, except that the substrate 521 is a fiber optical plate.

[0061] Specifically, such as Figure 4 As shown, the fiber guide plate is provided with a plurality of fiber guides perpendicular to the surface, and the visible light generated by the second scintillator layer 53 is refracted to the first visible light sensor 52 through each fiber guide and absorbed, which can effectively Reduce the divergence of visible light.

Embodiment 3

[0063] This embodiment provides a photodetection structure, which is basically the same as that of Embodiment 1 and Embodiment 2, except that the lower layer of the second scintillator layer 53 also includes a second visible light sensor (not shown in the figure). , used to convert the visible light passing through the second scintillator layer 53 into charges and store them in the second visible light sensor.

[0064] Further, it can also be extended to an interphase distribution structure of multi-layer scintillator layers and multi-layer visible light sensors. The more layers, the shorter the path of visible light, the slighter the divergence of light, and the clearer the image; at the same time, the scintillator layers of different layers use independent visible light sensors, the greater the X-ray energy, the deeper the irradiation depth, thus achieving Detection of multi-level X-rays.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com