Seamless water-stopping panel dam

A face dam and water stop technology, applied in dams, barrages, water conservancy projects, etc., can solve the problems of complex stress conditions of reinforced concrete face plates, complex interaction between face plates and plinths, and increase the difficulty of engineering design, so as to achieve deformation adaptability High, long durability, and the effect of reducing the risk of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

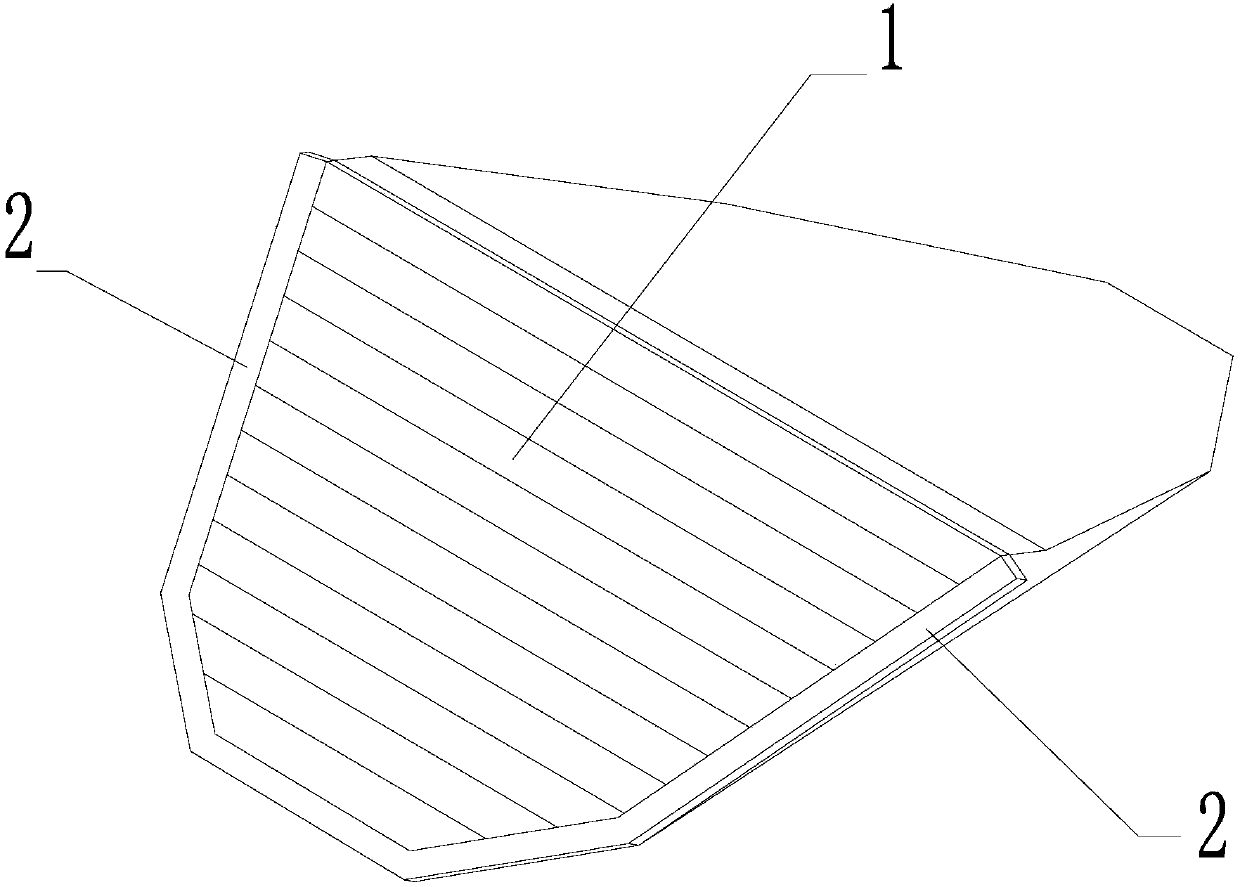

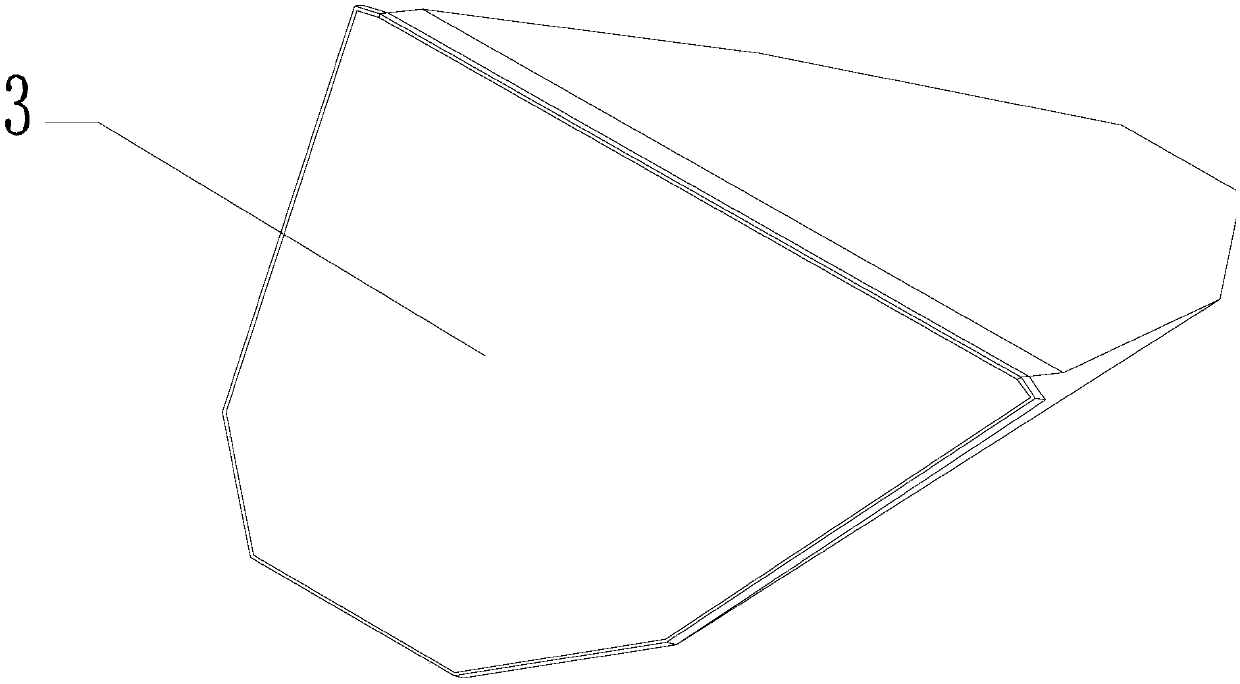

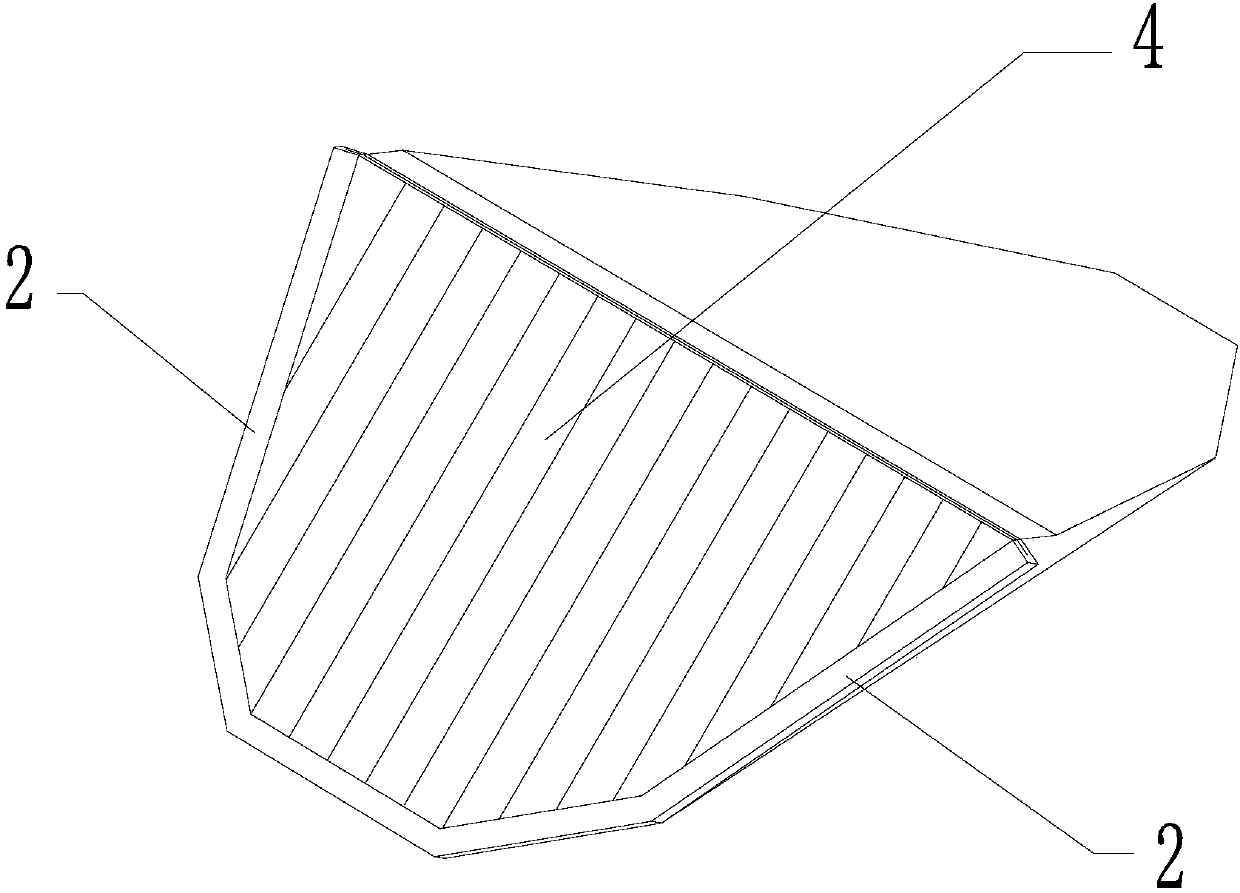

[0016] Such as figure 1 figure 2 and image 3 The shown seamless water-stop face dam includes a coplanar concrete support surface formed by extruded side walls 1 and plinth 2 and an integral water-stop layer 3 arranged on the concrete support surface. A surface protective concrete panel 4 is arranged on the waterproof layer 3 , and a cover plate of the toe board 2 is arranged at the toe board 2 .

[0017] This application abandons the seam sealing scheme that has been used in the prior art, and adopts a "sandwich structure" in which an integral water sealing is provided between the concrete panel and the extruded side wall 1, fully utilizing the advantages of different materials, and eliminating the gap between the panels. The vertical joints and the peripheral joints between the panel and the plinth improve the integrity of the water stop system, simplify the construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com