Tea baking machine and hot air exhaust method thereof

A technology for roasting machines and tea leaves, applied in dryers, drying, heating devices, etc., can solve problems such as threats to the life safety of workers, low resource utilization, and poor safety performance, so as to avoid heat loss and improve thermal insulation effects. , to avoid the effect of scalding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

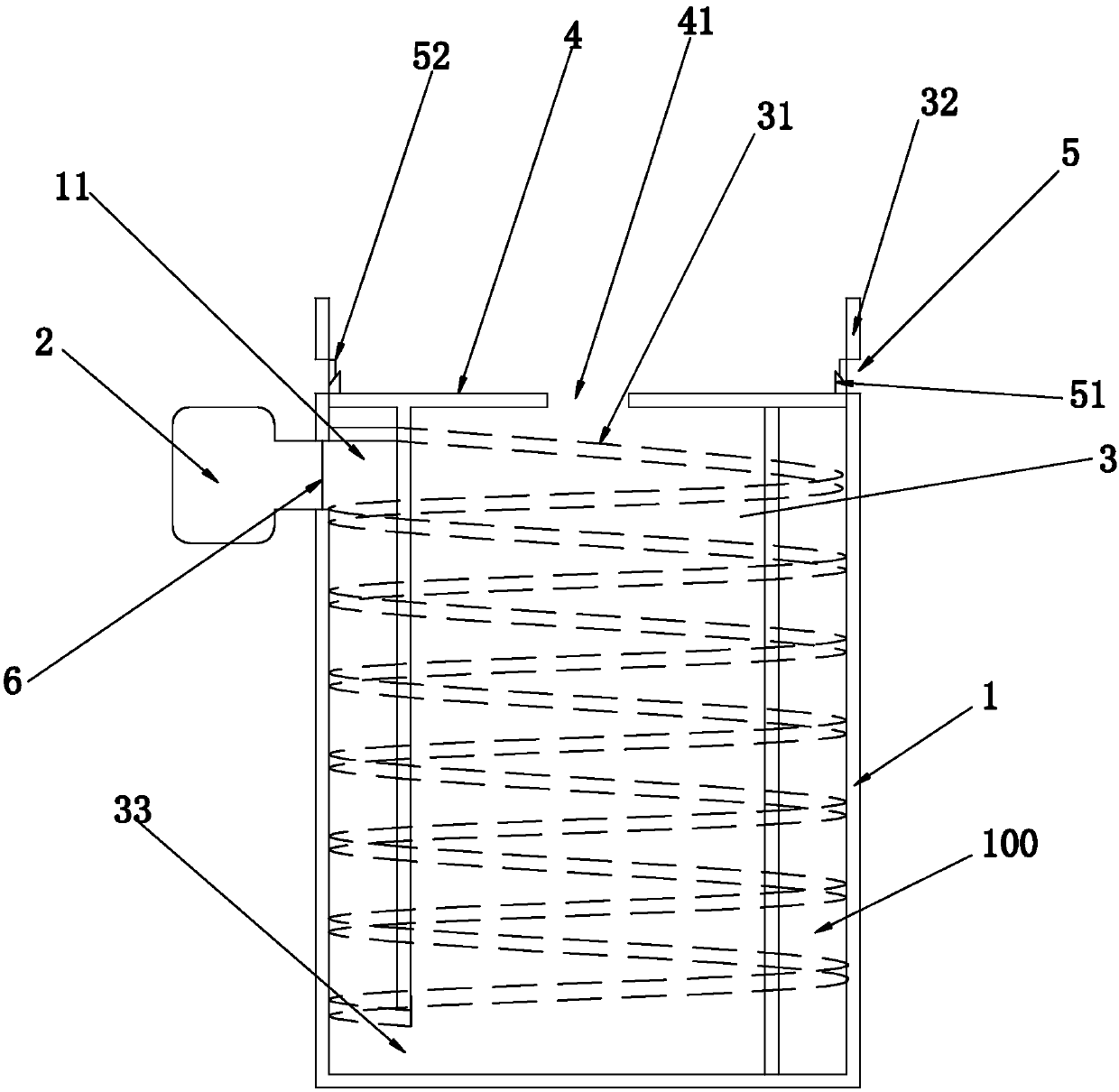

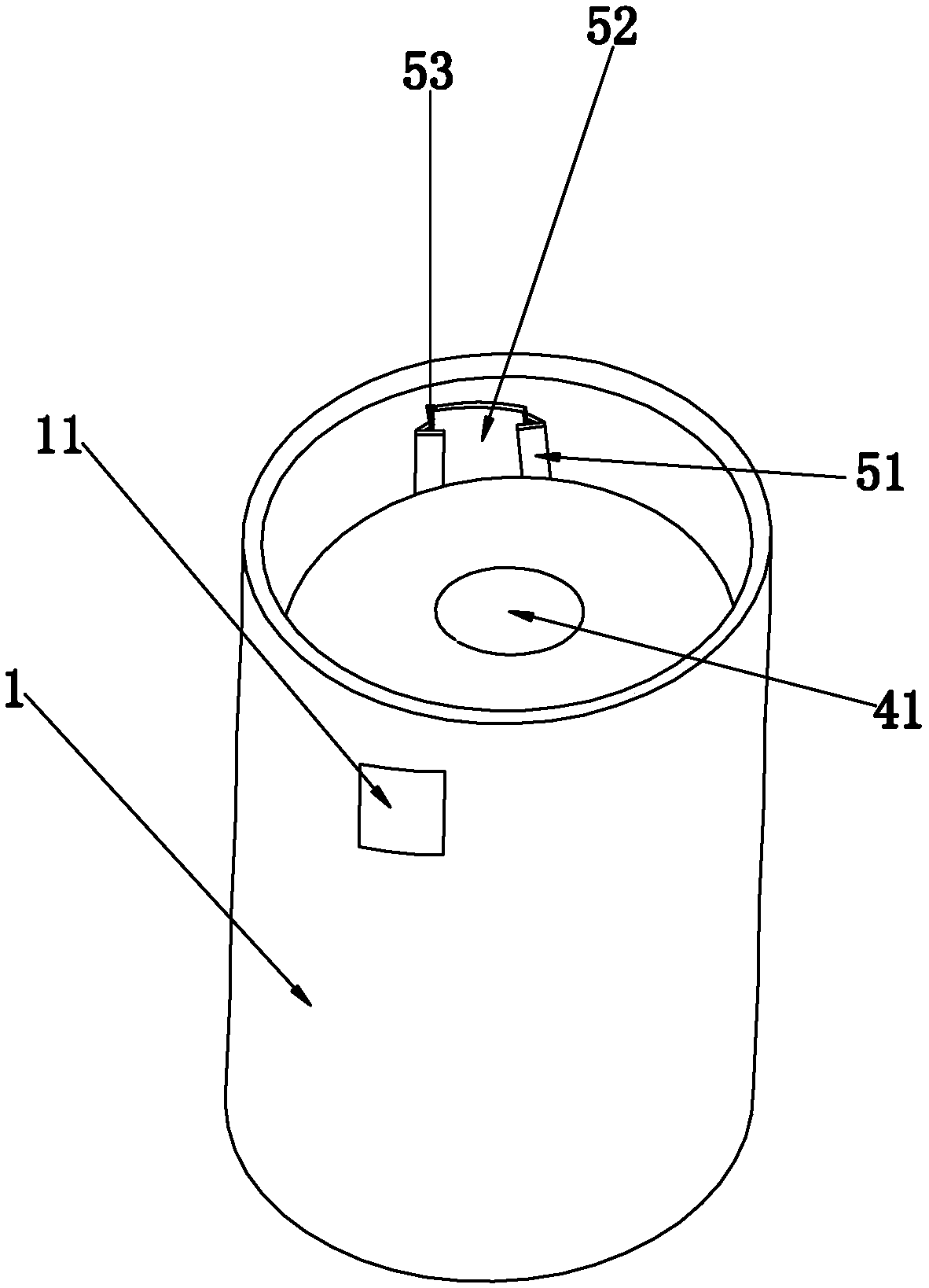

[0034] A tea roasting machine, comprising a cylinder 1 with an inner cavity 3 and a heating assembly arranged at the inner cavity 3, the top 4 of the cylinder 1 is provided with a hot air outlet 41 communicating with the inner cavity 3, which is specifically implemented in the present invention In an example, the side wall of the cylinder 1 is hollow, and the hollow part constitutes an air passage 100. The outer wall of the cylinder 1 near the top is provided with a vent 11 communicating with the air passage, and a blower is connected to the vent 11. 2. The connection between the ventilation channel 100 and the side wall of the cylinder body 1 near the bottom is provided with an air guide port 33 communicating with the inner cavity 3, and the ventilation channel 100 starts from the ventilation port 11 and guides the air channel to the bottom of the cylinder body along the circumference of the cylinder body. A spiral wind deflector 31 extends from the tuyere 33 .

[0035] By ad...

Embodiment 2

[0045] Embodiment 2, the difference with embodiment 1 is

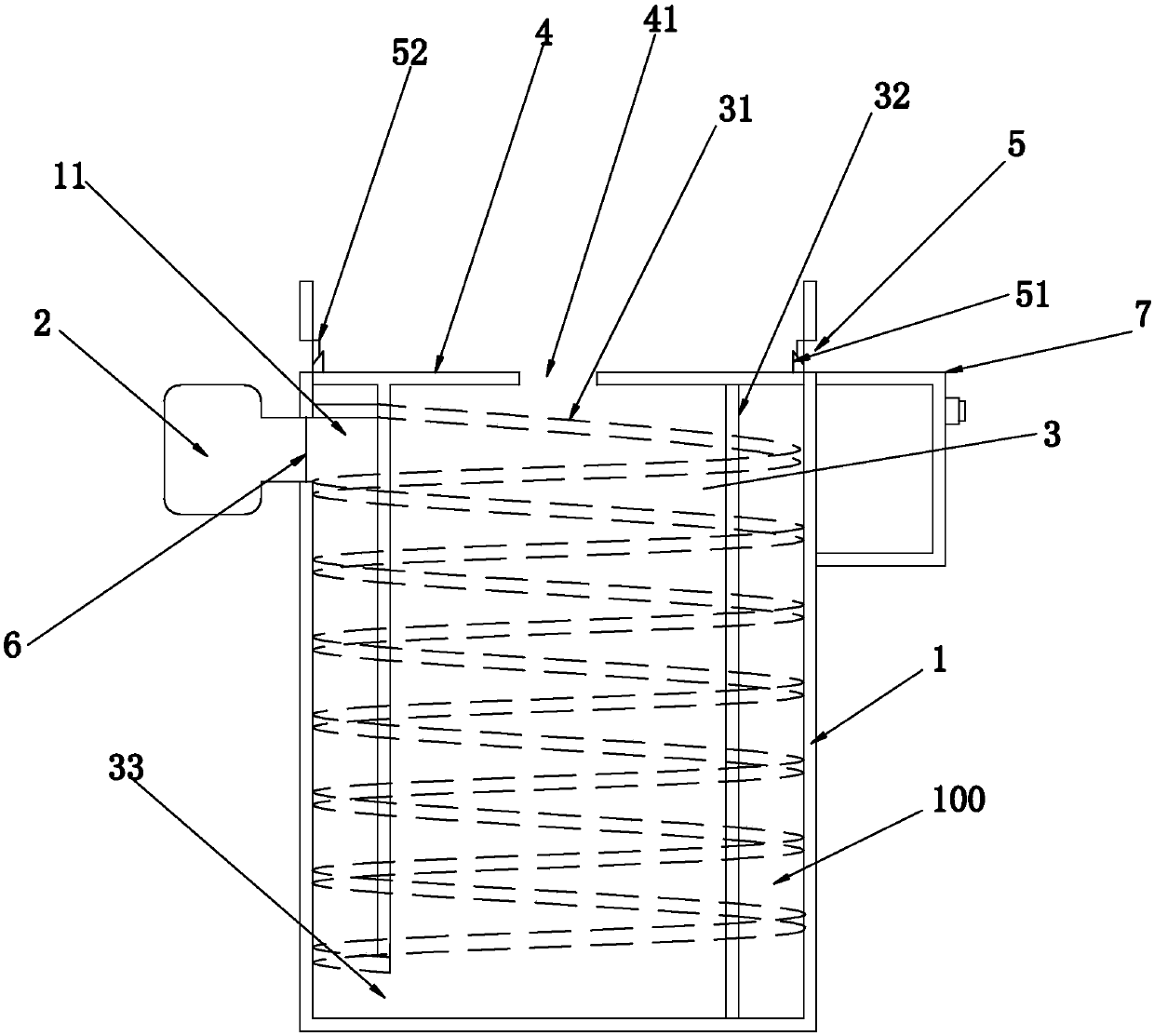

[0046] like image 3 and Figure 5 As shown, the present invention is further provided that the hot air outlet 41 is provided with a temperature sensor 8, the temperature sensor 8 is electrically connected to the controller 7, and the blower 2 and the heating assembly are respectively electrically connected to the controller 7.

[0047] Preferably, the heating assembly includes an electric heating wire connected to the controller 7, and the electric heating wire is composed of a plurality of U-shaped copper rods connected in series.

[0048] By adopting the above technical solution: the temperature at the outlet of the hot air is effectively monitored to ensure the maximum efficiency of the tea roaster, and it is convenient to control the temperature at the outlet of the hot air.

Embodiment 3

[0049] Embodiment 3, the difference with embodiment 1 is

[0050] like Figure 4 As shown, in the specific embodiment of the present invention, the book cylinder 1 can be fixed on the support 8, and the bottom of the support 8 is provided with running wheels 81 for rolling.

[0051] By adopting the above-mentioned technical scheme: because the cylinder body 1 is relatively heavy, it is very troublesome in the process of handling, and the cylinder body 1 is fixed on the bracket 8, and the cylinder body 1 is in the process of handling through the walking wheels 81 at the bottom of the bracket 8. It is more convenient in order to improve the efficiency of production.

[0052] like Image 6 and Figure 7 As shown, the tea baking machine in the prior art needs to heat the temperature of the heating assembly to 150°C to have a baking temperature of 73°C~80°C, while the tea baking machine provided by the present invention only needs to heat the temperature of the heating assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com