Corrosion inhibitor pre-filming thickness test device and method

A test method and technology for corrosion inhibitors, applied in the direction of measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

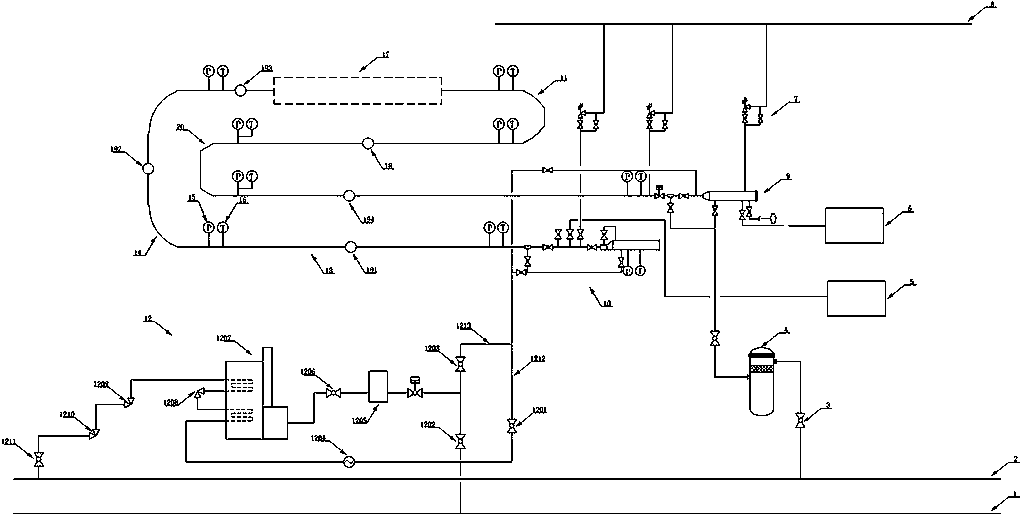

[0106] In this embodiment, the device is intended to be installed on the bypass pipeline of a section of the pipeline on site.

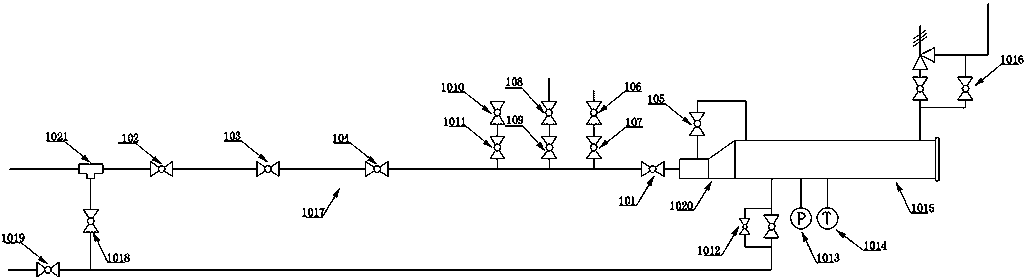

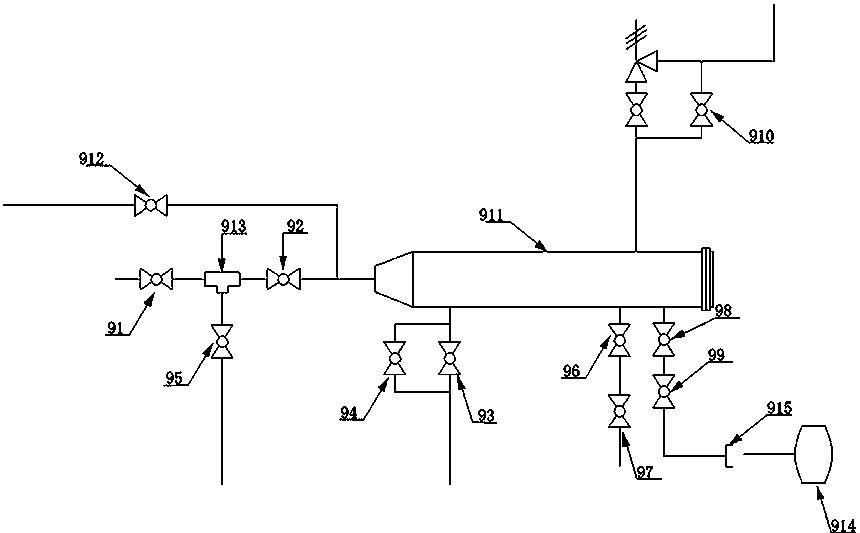

[0107] Such as figure 1 As shown in the schematic diagram of the loop test device, a corrosion inhibitor pre-film thickness test device includes fuel gas pipeline 1, acid gas pipeline 2, return valve 3, gas-water separator 4, corrosion inhibitor filling system 5, sewage treatment System 6, vent safety valve 7, vent pipeline 8, ball collection system 9, ball delivery system 10, first elbow test system 11, temperature and pressure regulation system 12, horizontal pipe section test system 13, second elbow test system 14, Pressure sensor 15, temperature sensor 16, undulating pipe section test system 17, fifth test point 18, film thickness detection piece 19, third elbow test system 20;

[0108] The temperature and pressure regulation system 12 is connected to the fuel gas pipeline 1, the acid gas pipeline 2 and the ball system 10, the horizontal pipe se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com