Secondary cell charging method

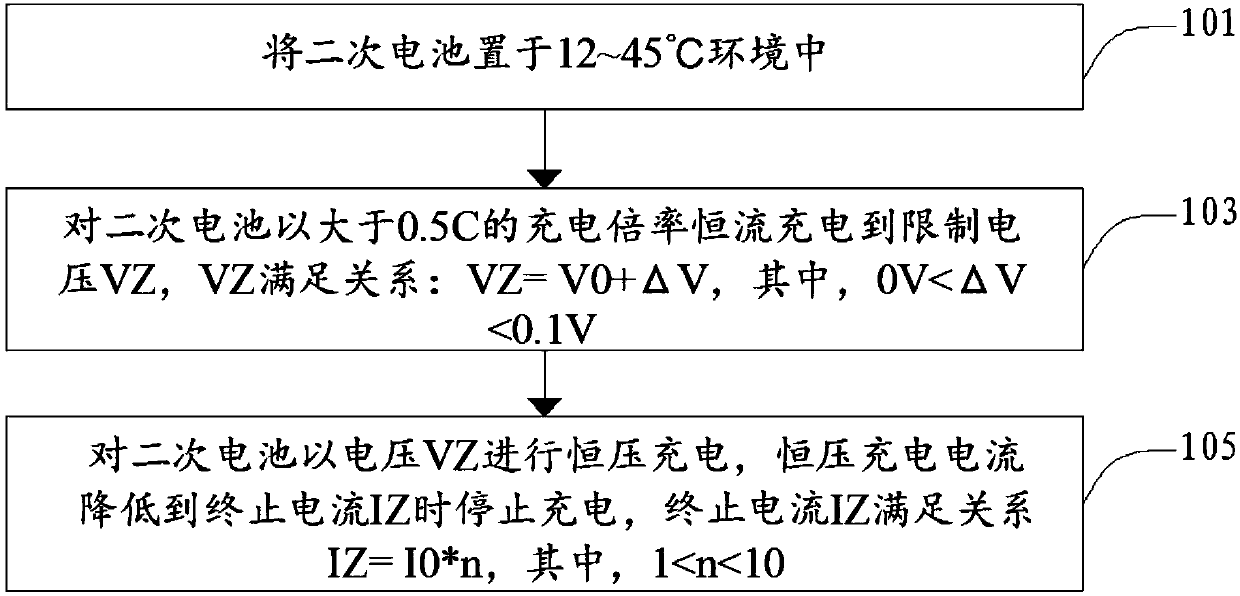

A technology of secondary battery and charging method, which is applied in secondary battery charging/discharging, secondary battery, secondary battery repair/maintenance, etc., and can solve the problem of limited service life of battery cells, shortened charging time, and inability to fully charge batteries, etc. problem, to achieve the effect of prolonging the service life, reducing the time of high-voltage charging, and increasing the charging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 201, placing the manufactured secondary battery in a constant temperature environment of 45°C.

[0034] The anode of the secondary battery is graphite, and the cathode is lithium cobalt oxide. At 25°C, the fully charged rated charging capacity of the secondary battery Q 0 3730mAh, fully charged cut-off voltage V 0 is 4.45V.

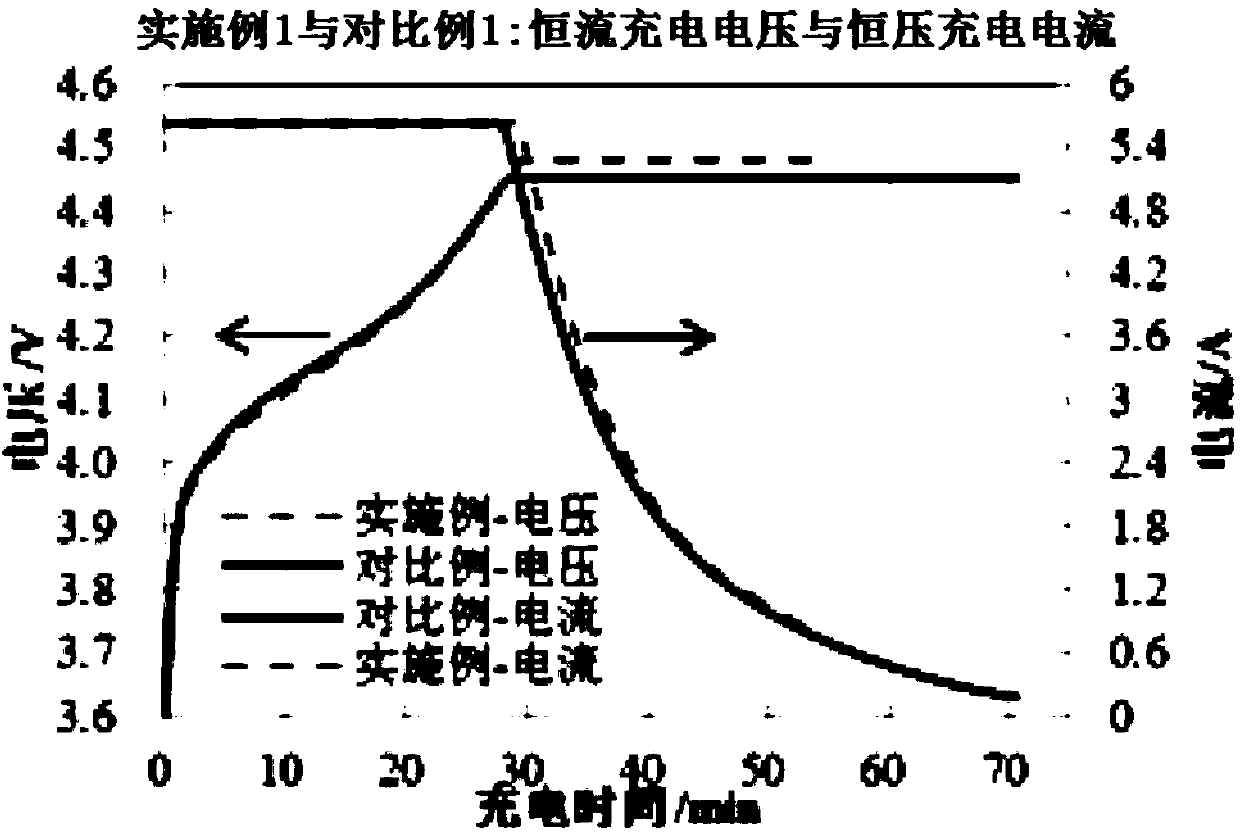

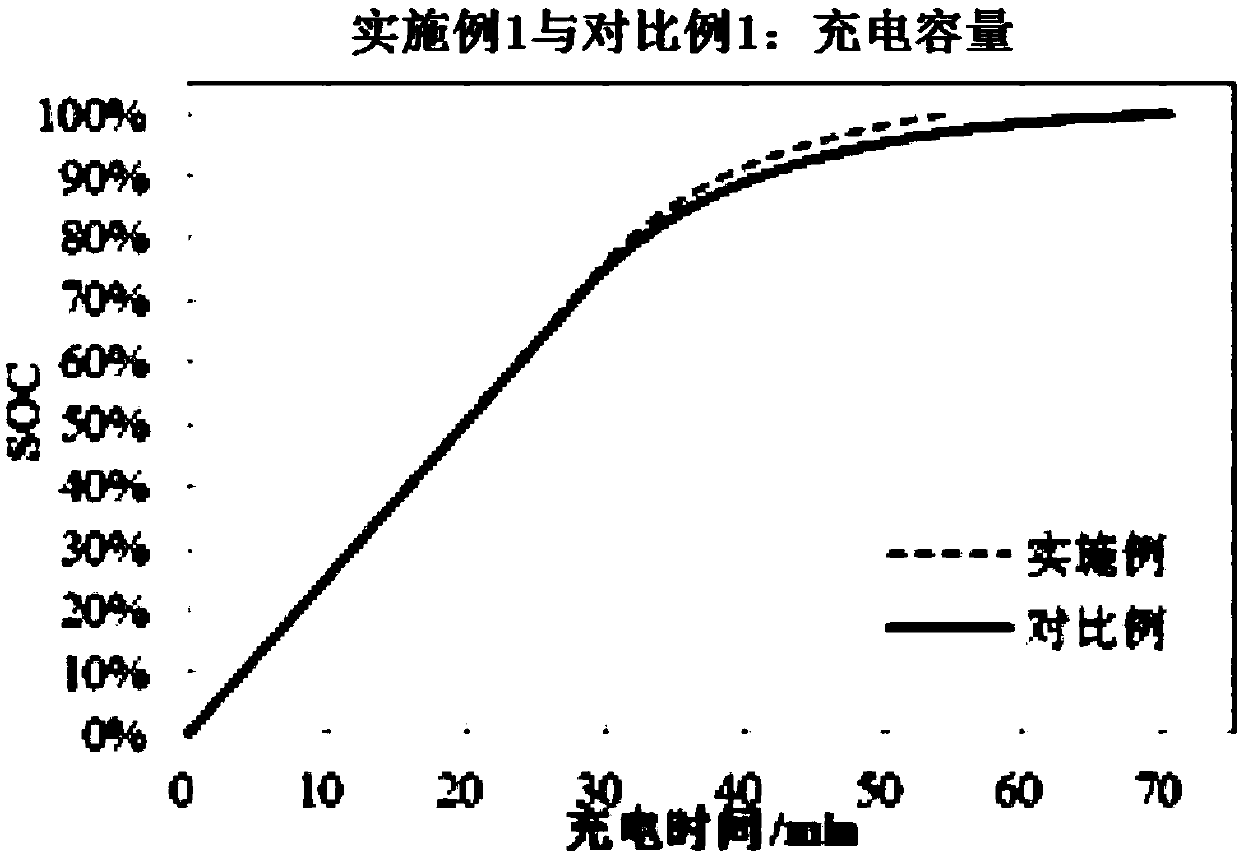

[0035] Step 203, charge the secondary battery with a constant current at a charge rate of 1.5C to a limit voltage of 4.48V.

[0036] Step 205, charge the secondary battery with a constant voltage of 4.48V to a termination current of 0.746A, and stop charging.

Embodiment 2

[0045] Step 301, placing the fabricated secondary battery in a constant temperature environment of 25°C.

[0046] The anode of the secondary battery is graphite, and the cathode is lithium cobalt oxide. At 25°C, the fully charged rated charging capacity of the secondary battery Q 0 3500mAh, fully charged cut-off voltage V 0 is 4.40V.

[0047] Step 303, charge the secondary battery with a constant current at a charge rate of 2C to a limit voltage of 4.45V.

[0048] Step 305, charge the secondary battery with a constant voltage of 4.45V to a termination current of 0.81A, and stop charging.

Embodiment 3

[0054] Step 401, placing the manufactured secondary battery in a constant temperature environment of 25°C.

[0055] The anode of the secondary battery is graphite, and the cathode is lithium iron phosphate. At 25°C, the fully charged rated charging capacity of the secondary battery Q 0 1850mAh, fully charged cut-off voltage V 0 It is 3.70V (the known constant current charging limit voltage V of this battery system 0 3.6 ~ 3.8V).

[0056] Step 403, charge the secondary battery with a constant current at a charge rate of 3C to a limit voltage of 3.80V.

[0057] Step 405, charge the secondary battery with a constant voltage of 3.80V to a termination current of 0.63A, and stop charging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com