A five-stage phosphate formation process

A phosphate and process technology, applied in the direction of capacitors, circuits, electrical components, etc., can solve the problems of capacity loss, failure to meet demand, and limited improvement, and achieve the effects of no capacity loss, reduced leakage current, and weakened deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

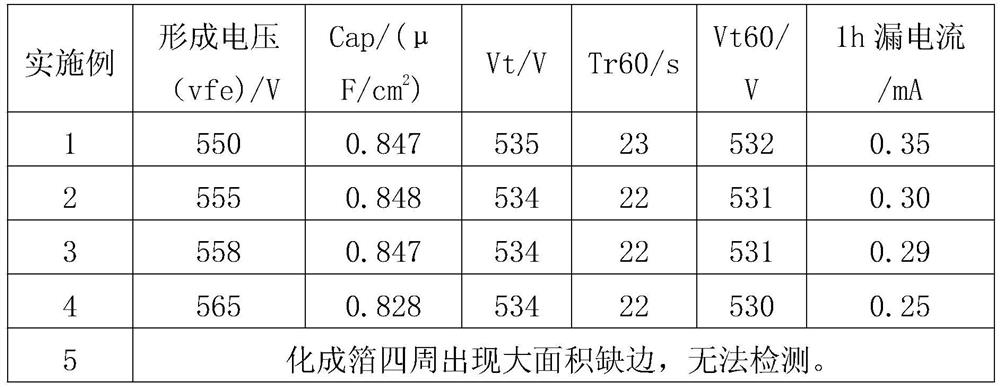

Embodiment 1

[0061] The specific operation steps are as follows:

[0062] (1) Boiling in high temperature water: immerse in water above 95°C for 11 minutes.

[0063] (2) One-stage formation: anodic oxidation with an aqueous solution of 1g / L ammonium dihydrogen phosphate, 2g / L citric acid and 2g / L triammonium citrate, the treatment time is 8min, the treatment temperature is 90°C, and the formation is to 120V .

[0064] (3) Secondary formation: anodic oxidation with an aqueous solution of 1g / L citric acid and 2g / L triammonium citrate, the treatment time is 8min, the treatment temperature is 90°C, and the formation is up to 250V.

[0065] (4) Tertiary formation: use an aqueous solution with a concentration of 0.5g / L citric acid and 1g / L triammonium citrate for anodic oxidation, the treatment time is 8min, the treatment temperature is 90°C, and the formation is up to 380V.

[0066] (5) Four-stage chemical conversion: use an aqueous solution with a concentration of 0.2g / L citric acid and 0.6g...

Embodiment 2

[0078] The specific operation steps are the same as in Example 1, except that 1 g / L of ammonium dihydrogen phosphate is added to the secondary forming solution. The difference is that the formation voltage (that is, the five-level formation voltage and repair voltage) is 555V.

[0079] Anodized under the condition of forming voltage of 555V, using Example 2, slight corrosion occurs on the foil edge, and the capacity of the foil is 0.848μF / cm 2 , the withstand voltage value is 534V, the boost time after 1h boiling is 22s, and the leakage current is 0.3mA for 1h. Slight corrosion on foil edge.

Embodiment 3

[0081] The specific operation steps are the same as in Example 1, except that 1 g / L ammonium dihydrogen phosphate is added to the secondary forming solution, and 0.5 g / L ammonium dihydrogen phosphate is added to the tertiary forming solution. The difference is that the formation voltage (that is, the five-level formation voltage and repair voltage) is 558V.

[0082] Anodized at a formation voltage of 558V, the foil capacity is 0.847μF / cm 2 , the withstand voltage value is 534V, the boost time after 1h boiling is 22s, and the leakage current is 0.29mA for 1h. The lack of edges in the formed foil is more obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com