Novel single-phase cylindrical transverse flux switched reluctance linear motor

A technology of transverse magnetic flux and switched reluctance, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of low motor output volume ratio, reduce motor output volume ratio, and increase motor eddy current loss, etc. The effect of engineering application value, small eddy current loss and large average output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

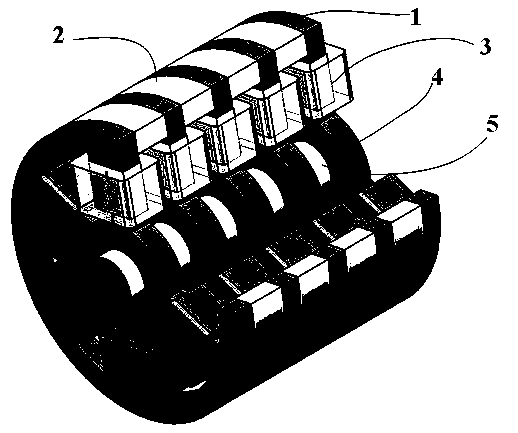

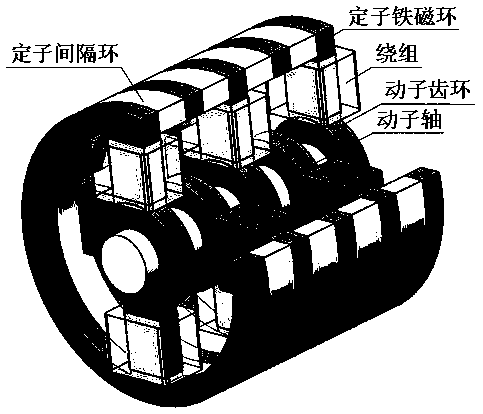

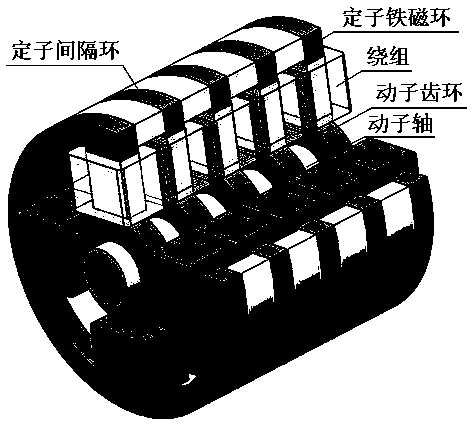

[0022] The novel single-phase cylindrical transverse flux switched reluctance linear motor of this embodiment is composed of a stator ferromagnetic ring, a stator spacer ring, a stator winding, a mover gear ring, and a mover shaft. The ferromagnetic rings of the stator and the spacer rings of the stator are arranged alternately, the gear rings of the mover are sleeved on the shaft of the mover, and the interval between adjacent stator rings is the same as that of the mover rings; two adjacent stator windings in the circumferential direction The direction of winding is opposite; all windings in the longitudinal direction are wound in the same direction. There are 2n teeth in the circumferential direction, and n is the number of pole pairs; the angle between two adjacent teeth is staggered by 360° / 2n.

[0023] In this implementation case, a new type of singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com