Buck-boost LED driving circuit

A technology for driving circuits and lighting circuits, which is applied in the direction of electric light sources, electrical components, electroluminescent light sources, etc., can solve the problems of high switching frequency switching loss, lower system conversion efficiency, etc., reduce power consumption, simplify peripheral applications, Effect of system cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

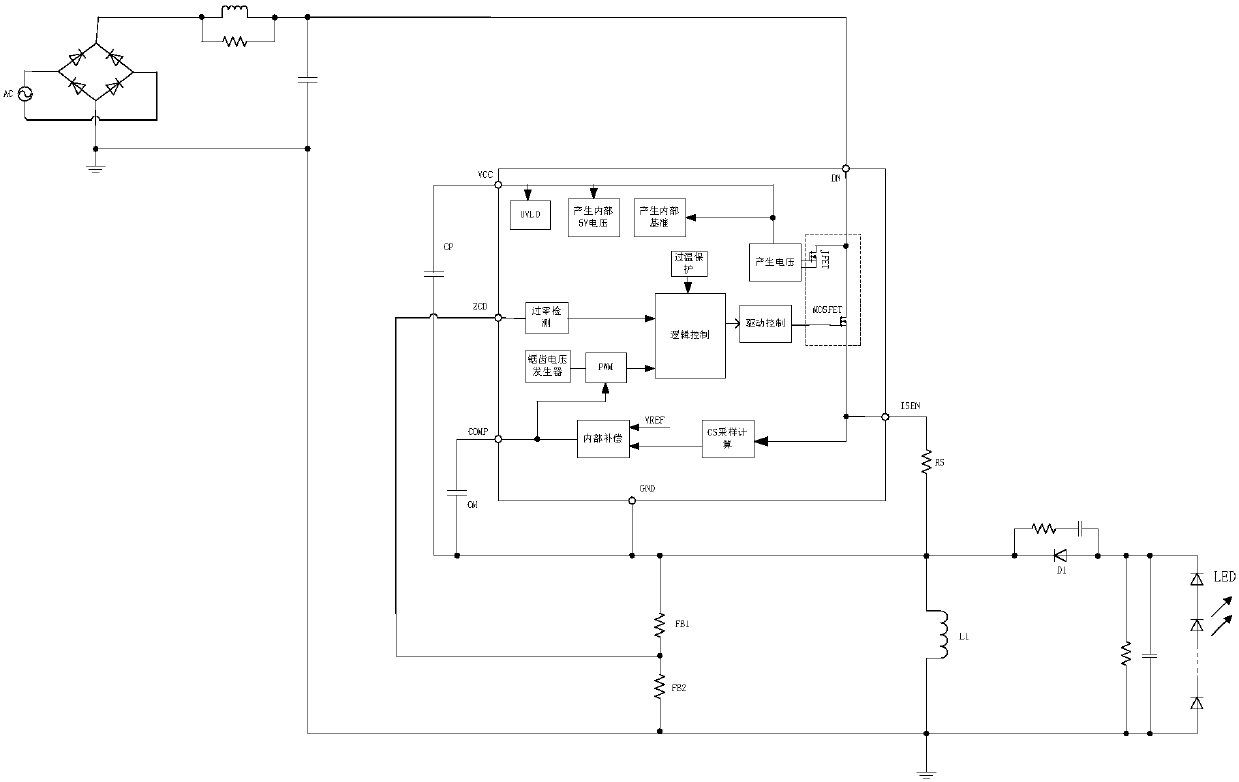

[0026] Such as figure 1 As shown, in the Buck-boost LED drive circuit of the present invention, the applicable lighting circuit includes an inductor L1, LED, capacitor and freewheeling diode D1, the capacitor is arranged at both ends of the LED light group, one end of the capacitor is connected to the inductor, and the other end A freewheeling diode D1 is set between the inductor and the inductor.

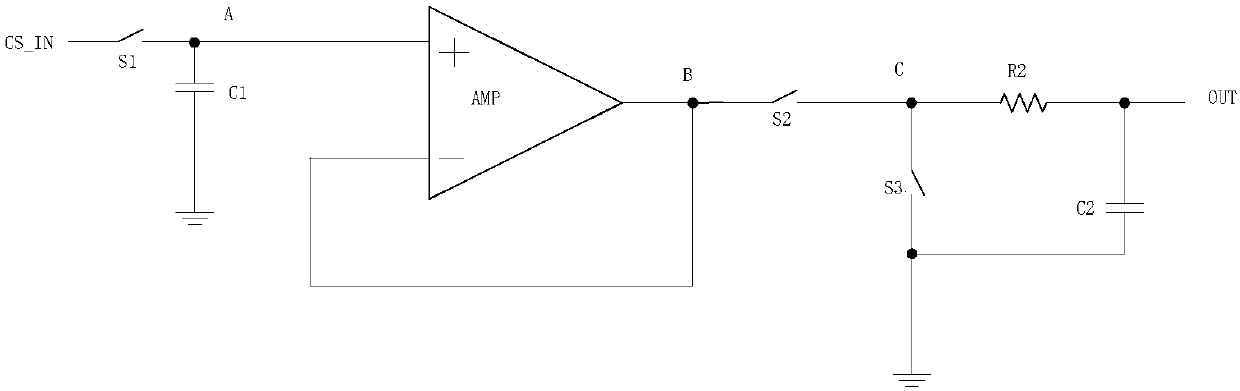

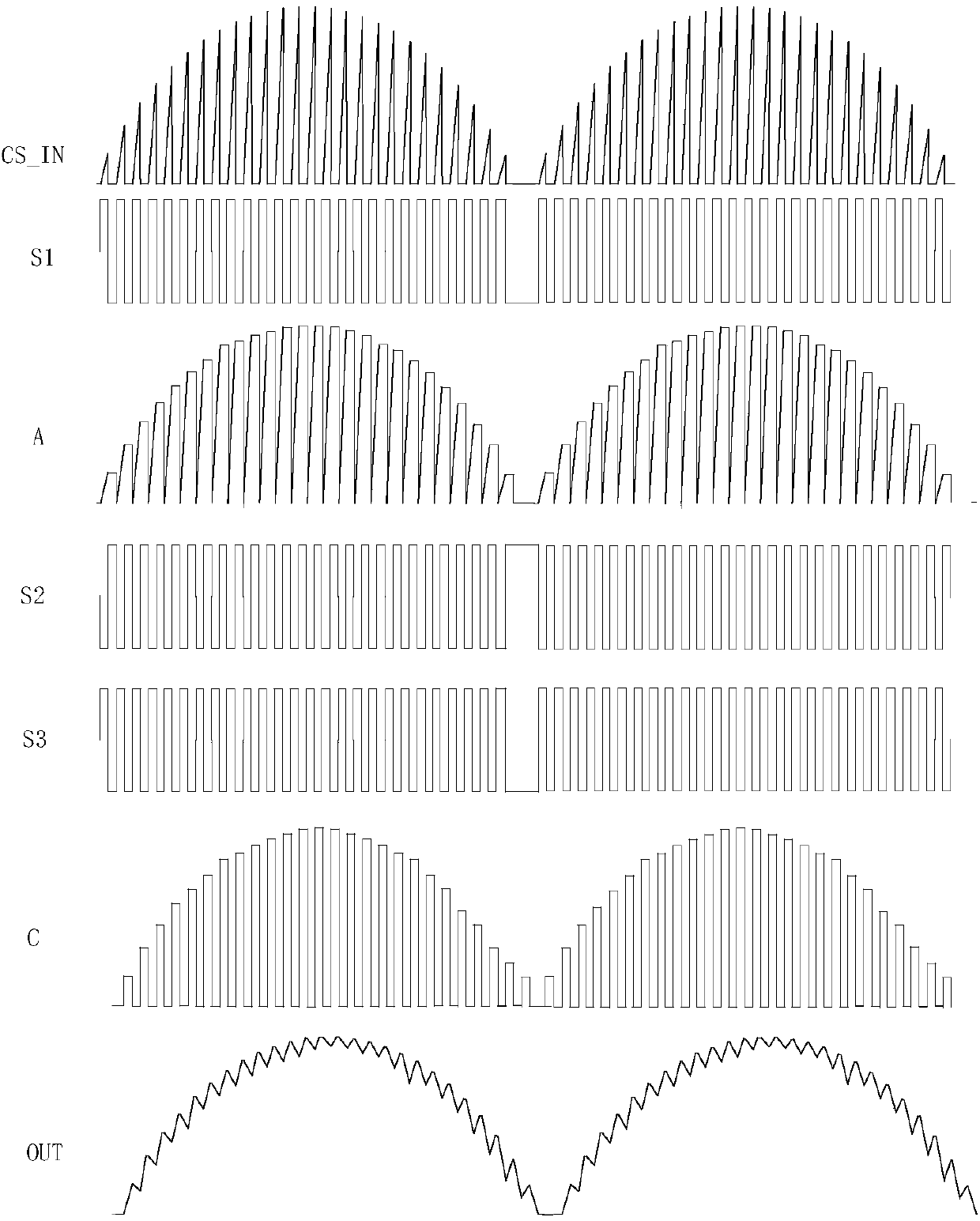

[0027] The drive circuit includes a high-voltage MOSFET tube, a JFET tube, a voltage generation module, a drive control module and a logic control module, a sampling resistor RS, a CS sampling calculation module, an internal compensation module, a sawtooth voltage generator, and a zero-crossing detection module.

[0028] Among them, the drain of the JFET tube is connected to the DC power supply, the drain of the high-voltage MOSFET ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com