Preparation method for ceramic ball enhanced magnesium based composite

A composite material and ceramic ball technology, which is applied in the field of preparation of ceramic ball reinforced magnesium-based composite materials, can solve the problems of segregation of ceramic balls, long time, and product pores, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] see figure 1 and figure 2 Shown, the preparation method of ceramic ball reinforced magnesium-based composite material of the present invention, comprises the steps:

[0025] Step 1) Mix ceramic balls and water glass evenly according to a certain ratio, put them into a ceramic tube mold to make a green body, dry the green body in an oven at a temperature of 150-200°C for 1.5-2 hours, and prepare ceramics with a certain strength ball prefabricated body;

[0026] Step 2) Melting the magnesium alloy in a smelting furnace fed with argon gas at a melting temperature of 650-750°C to obtain a molten magnesium alloy;

[0027] Step 3) Put the ceramic ball prefabricated body obtained in step 1) into the hydraulic press mold, and then pour the molten magnesium alloy obtained in step 2) into the hydraulic press mold, pressurize the pressure head and keep the pressure for a certain period of time, and the ceramic ball is reinforced. Magnesium-based composites.

[0028] Step 1) T...

Embodiment 1

[0035] Embodiment 1: magnesium matrix is Mg

[0036] Step 1) Mix ceramic balls and water glass evenly with a mass ratio of 10:1, put them into a ceramic tube mold to make a green body, dry the green body in an oven at 200°C for 1.5 hours, and prepare a certain strength ceramic ball prefabricated body;

[0037] Step 2) Melting the as-cast Mg ingot in a smelting furnace fed with argon gas at a melting temperature of 680°C to obtain molten magnesium;

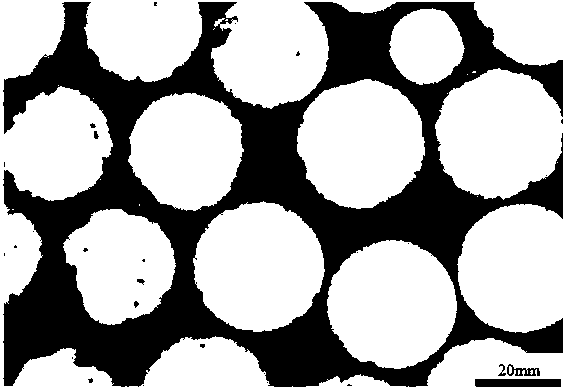

[0038] Step 3) Put the ceramic ball preform obtained in step 1) into the hydraulic press mold, then pour the molten magnesium obtained in step 2) into the hydraulic press mold, pressurize the pressure head to 30MPa and keep the pressure for 5s, and the ceramic ball is obtained Reinforced magnesium matrix composites. Such as figure 1 As shown, the ceramic balls are evenly distributed.

Embodiment 2

[0039] Embodiment 2: Magnesium substrate is AZ91D magnesium alloy

[0040] Step 1) Mix ceramic balls and water glass evenly with a mass ratio of 10:1, put them into a ceramic tube mold to make a green body, and dry the green body at a temperature of 150°C in an oven for 2 hours to prepare a certain strength Ceramic ball prefabricated body;

[0041] Step 2) melting the as-cast AZ91D magnesium ingot in a smelting furnace fed with argon gas at a melting temperature of 700°C to obtain a molten magnesium alloy;

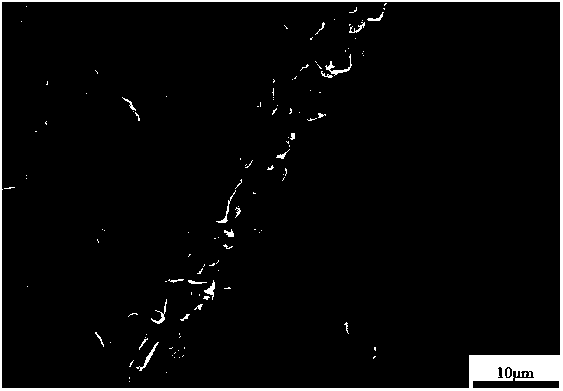

[0042] Step 3) Put the ceramic ball preform obtained in step 1) into the hydraulic press mold, then pour the molten magnesium alloy obtained in step 2) into the hydraulic press mold, pressurize the pressure head to 25MPa and keep the pressure for 8s, and the ceramic is obtained Ball-reinforced magnesium-based composites. Such as figure 2 As shown, no interfacial reaction occurred during the preparation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com