Preparation method for aluminum-coated ceramic substrate

A ceramic substrate and aluminum-coated technology, which is applied in the field of preparation of aluminum-coated ceramic substrates, can solve the problems of poor wettability of aluminum-ceramic interface and aluminum-coated ceramic substrates, and achieve the effect of solving poor wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

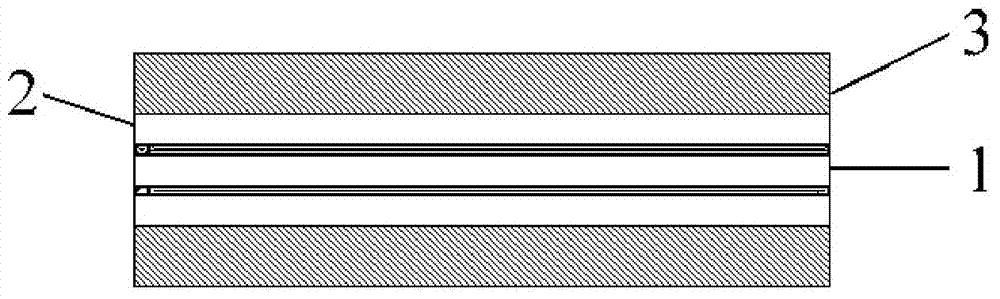

[0022] Embodiment one, such as figure 1 As shown, the preparation method of aluminum-coated ceramic substrates uses acid-base solution and deionized water to process transition metal copper sheets, Al 2 o 3 The ceramic substrate is cleaned to remove impurities on the surface of the material.

[0023] The surface of the aluminum sheet is polished with metallographic sandpaper to remove the surface oxide layer, followed by ultrasonic cleaning, spraying, pre-dehydration and other processes to clean the aluminum sheet to remove surface impurities.

[0024] According to the DBC process in Al 2 o 3 The surface of the ceramic substrate is coated with copper on both sides to form the substrate 1 . The temperature is set at 1065° C. to 1080° C., the sintering time is 20 minutes to 35 minutes, the atmosphere is a nitrogen protective atmosphere, and the oxygen content is 5 ppm to 40 ppm.

[0025] Place the cleaned aluminum sheet 2 on the surface of the copper sheet, and put the subs...

Embodiment 2

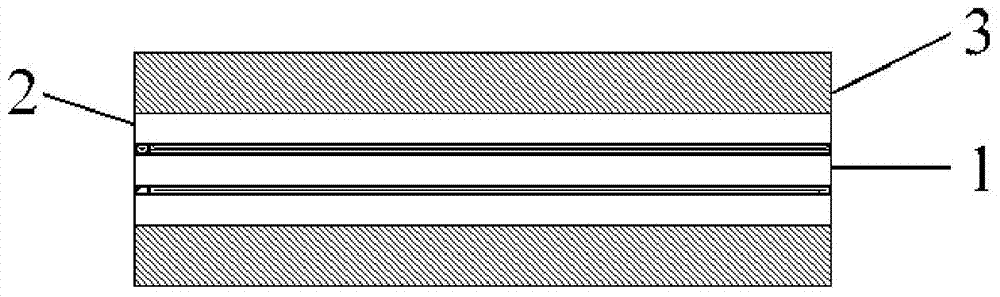

[0026] Embodiment two, such as figure 2 As shown, the preparation method of aluminum-coated ceramic substrates uses acid-base solution and deionized water to process transition metal zinc flakes, Al 2 o 3 The ceramic substrate is cleaned to remove impurities on the surface of the material.

[0027] The surface of the aluminum sheet is polished with metallographic sandpaper to remove the surface oxide layer, followed by ultrasonic cleaning, spraying, pre-dehydration and other processes to clean the aluminum sheet to remove surface impurities.

[0028] According to the electroless galvanizing process in Al 2 o 3 The surface of the ceramic base material is coated with zinc on both sides to form the substrate 1 .

[0029] Place the cleaned aluminum sheet 2 on the surface of the zinc sheet, put the substrate 1 into the hot pressing mold 3, and apply a pressure per unit area of 100N / m 2 ~20000N / m 2 , in a vacuum environment, heated to 380°C to 660°C, hot-pressed and sintere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com