Double-wire double-sided single-pass submerged-arc welding method for moderate thickness plates

A submerged arc welding, double-sided technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high welding heat input, low efficiency, complex welding process, etc., achieve large penetration, save time, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

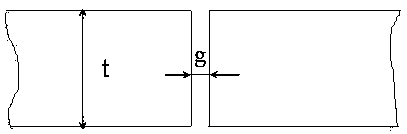

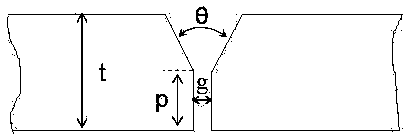

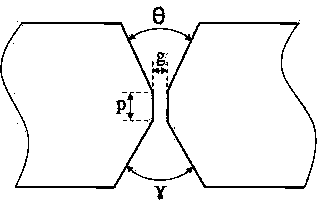

[0061] The base material for welding is a 20mm thick steel plate, and the groove is processed and assembled according to the parameters in Table 1. Two electrodes are connected in series to form a welding electrode group.

[0062] Table 1 Welding plate groove and assembly parameters

[0063]

[0064] Table 2 Parameters of series electrode group

[0065]

[0066] Table 3 Welding process parameters of 20mm thick steel plate

[0067]

Embodiment 2

[0069] The welding base material is a 35mm thick steel plate, and the groove is processed and assembled according to the parameters in Table 4. Three electrodes are connected in series to form a welding electrode group.

[0070] Table 4 Welding plate groove and assembly parameters

[0071]

[0072] Table 5 Parameters of series electrode group

[0073]

[0074] Table 6 35mm thick steel plate welding process parameters

[0075]

Embodiment 3

[0077] The base material for welding is a 50mm thick steel plate, and the groove is processed and assembled according to the parameters in Table 7. Three electrodes are connected in series to form a welding electrode group. The assembly parameters are according to Table 8, and the welding parameters for steel plate welding are set according to Table 9.

[0078] Table 7 Welding plate groove and assembly parameters

[0079]

[0080] Table 8 Parameters of series electrode group

[0081]

[0082] Table 9 50mm thick steel plate welding process parameters

[0083]

[0084] The above welded plates have been tested by X-ray and ultrasonic, and no welding defects have been found, and the welding process can meet the welding requirements of thick plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com