A leaf spring flexible multifunctional transport tool

A multi-functional, leaf spring technology, which is applied in transportation and packaging, conveyors, metal processing, etc., can solve the problems that the combined flexible tooling is not suitable for the transportation system, the flexible tooling does not meet the production requirements, and affects the efficiency of production and processing, so as to achieve saving Auxiliary time, guaranteed clamping and positioning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

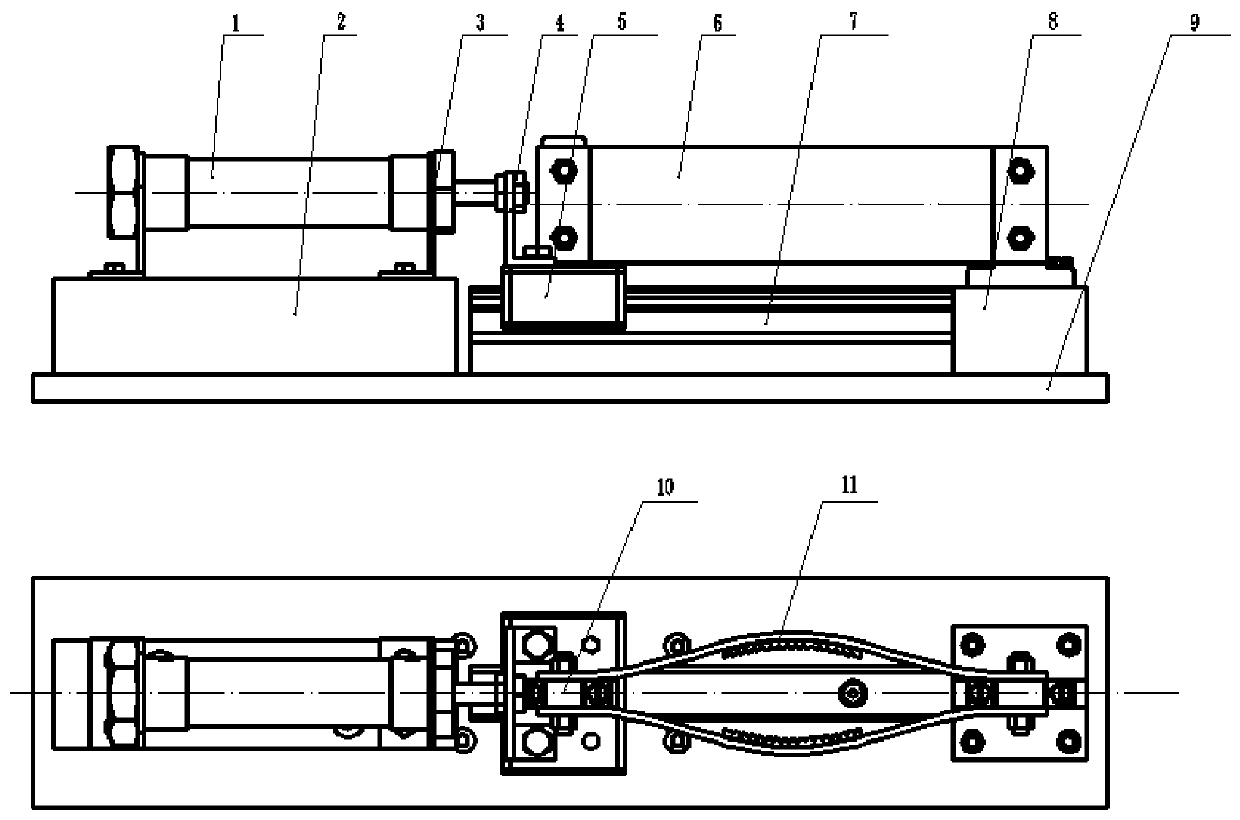

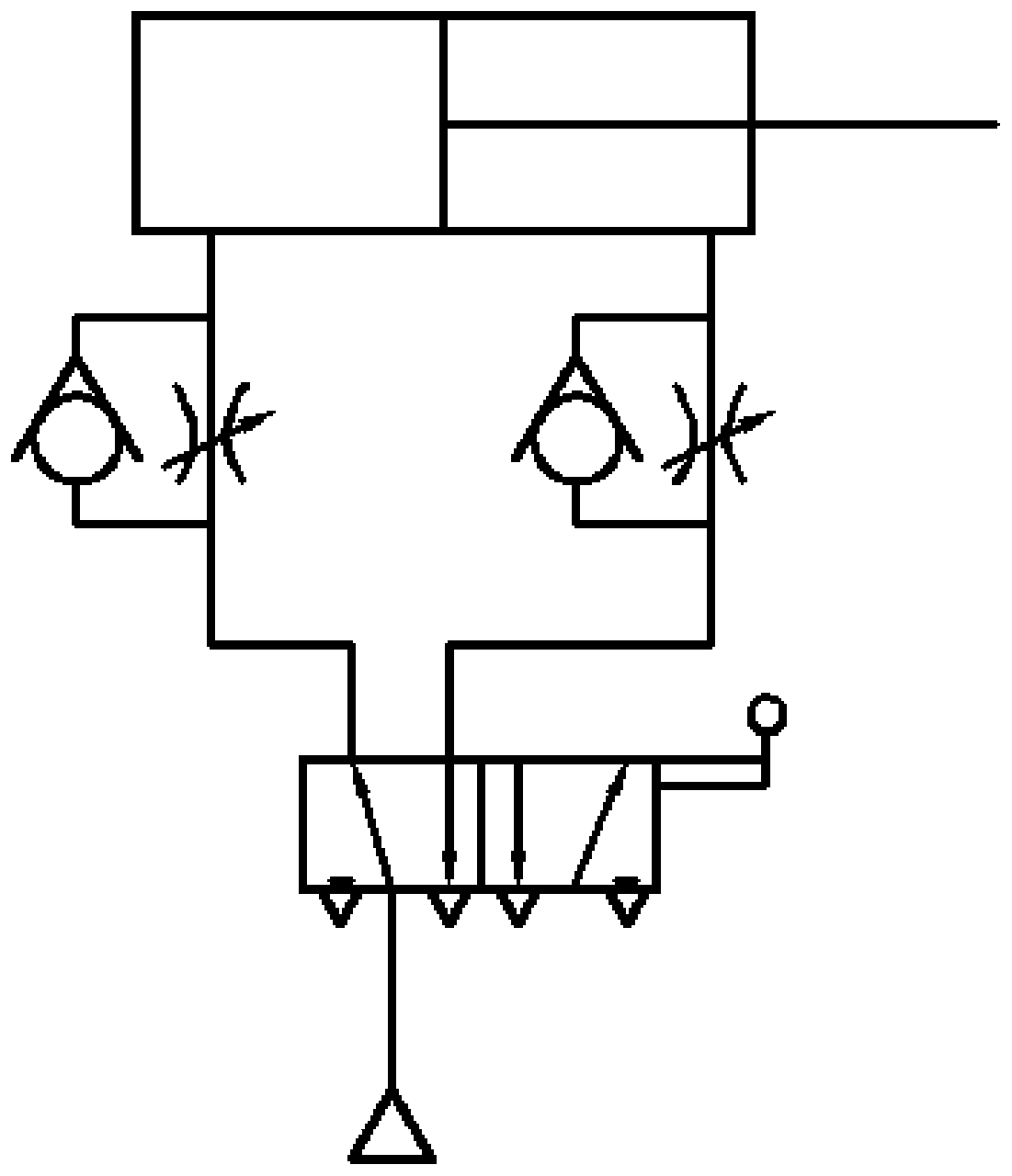

[0024] Pneumatic circuits such as figure 2 , The working mode of the circuit is to realize the reciprocating motion of the cylinder piston rod by controlling the manual reversing valve.

[0025] When the workpiece needs to be transported, the mechanical arm toggles the manual reversing valve, the piston rod of the cylinder is pushed out, the slider drives the leaf spring to expand, and the space for placing the workpiece is given. The mechanical arm picks up the workpiece and puts it in the middle of the leaf spring; the mechanical arm Turn the manual reversing valve again, the cylinder piston rod retracts, and the leaf spring clamps the workpiece.

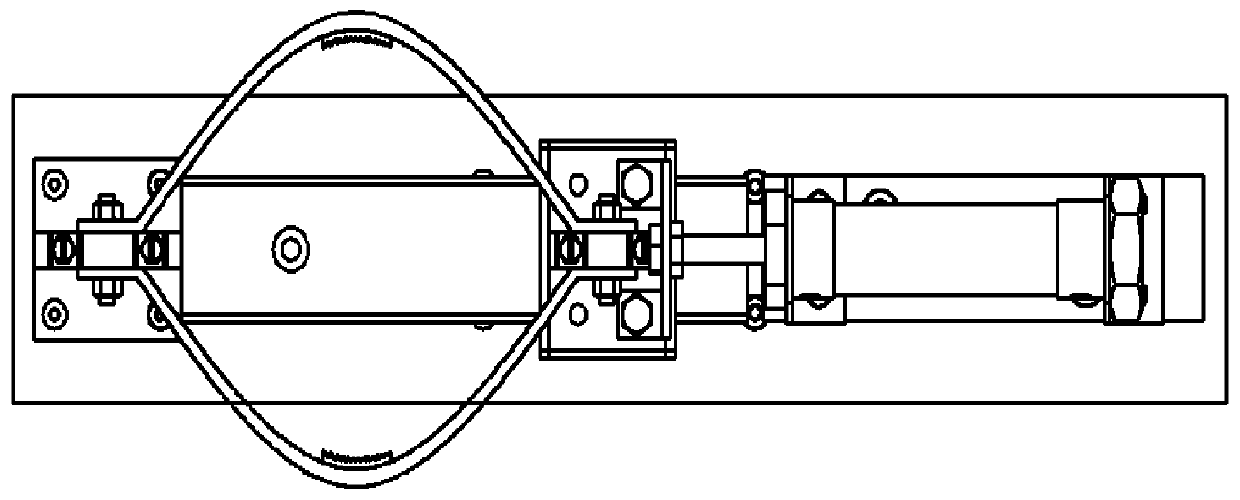

[0026] When the piston rod of the cylinder is stretched out, the leaf spring is stretched, and the state of the tooling is as follows: image 3 As shown; when the piston rod of the cylinder is retracted, the leaf spring is tightened, and the state of the tooling is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com