Preparation method of fluorosilicone non-ionic surfactant

A non-ionic surface, active agent technology, applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve the problem of less fluorosilicon non-ionic surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

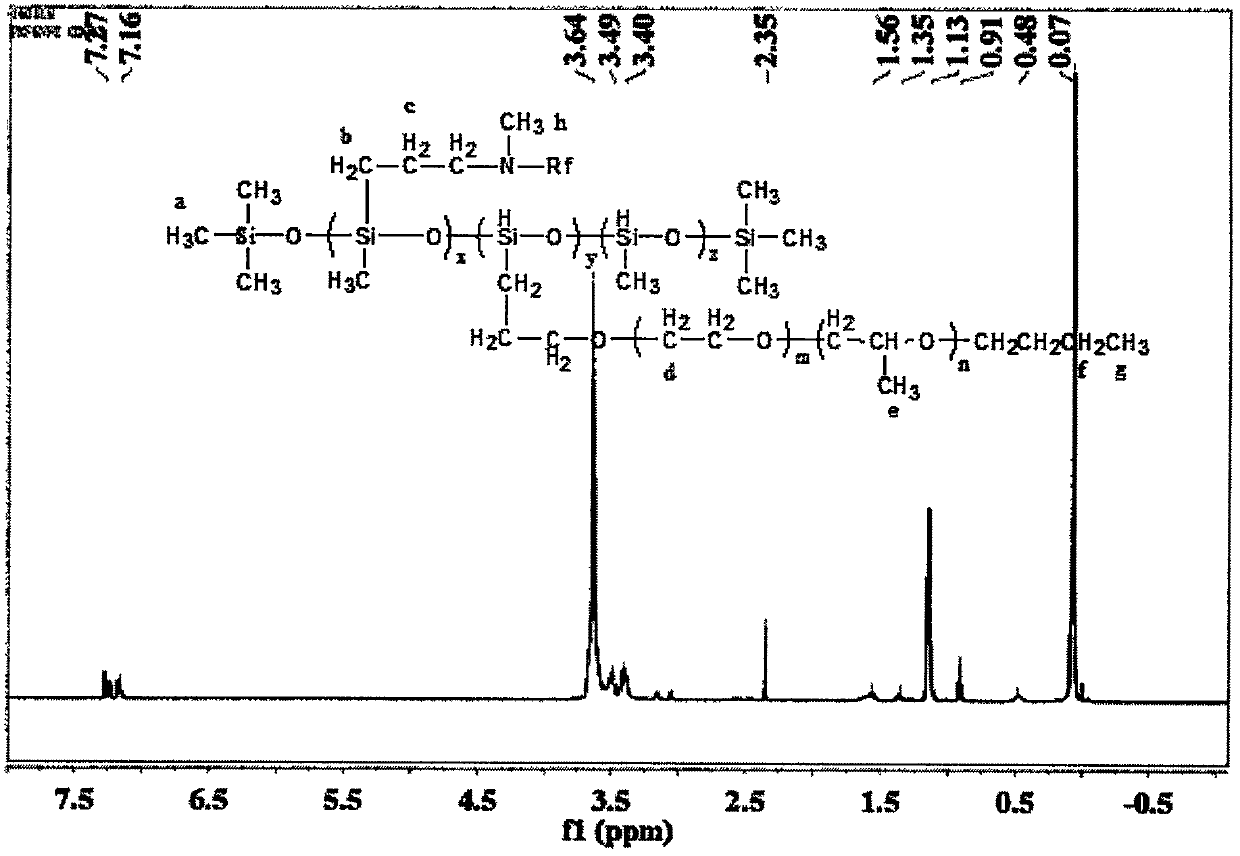

[0023] Low hydrogen-containing silicone oil PMHS [2.5g, n(Si-H)=4.95mmol], NF2[1.31g, n(C=C)=2.48mmol], F6[3.62g, n(C=C)=2.48 mmol] and toluene 10mL were added in a 100mL three-necked round-bottomed flask, then a certain amount of Karstedt catalyst with a concentration of 16.1g / L was added, connected with a condensing device, a magnetic stirring device and a thermometer, heated in an oil bath, and after a period of reaction, sampling and analysis Hydrosilylation reaction conversion rate until the conversion rate is substantially constant to end the reaction.

[0024] After the reaction, a yellow transparent solution was obtained, and the toluene was removed by rotary evaporation at 35°C, and then dried in a vacuum oven at 50°C for 4 hours to further remove residual toluene and unreacted volatile components to obtain a yellow Viscous liquid, the synthesis route of PF2F6 is as follows:

[0025]

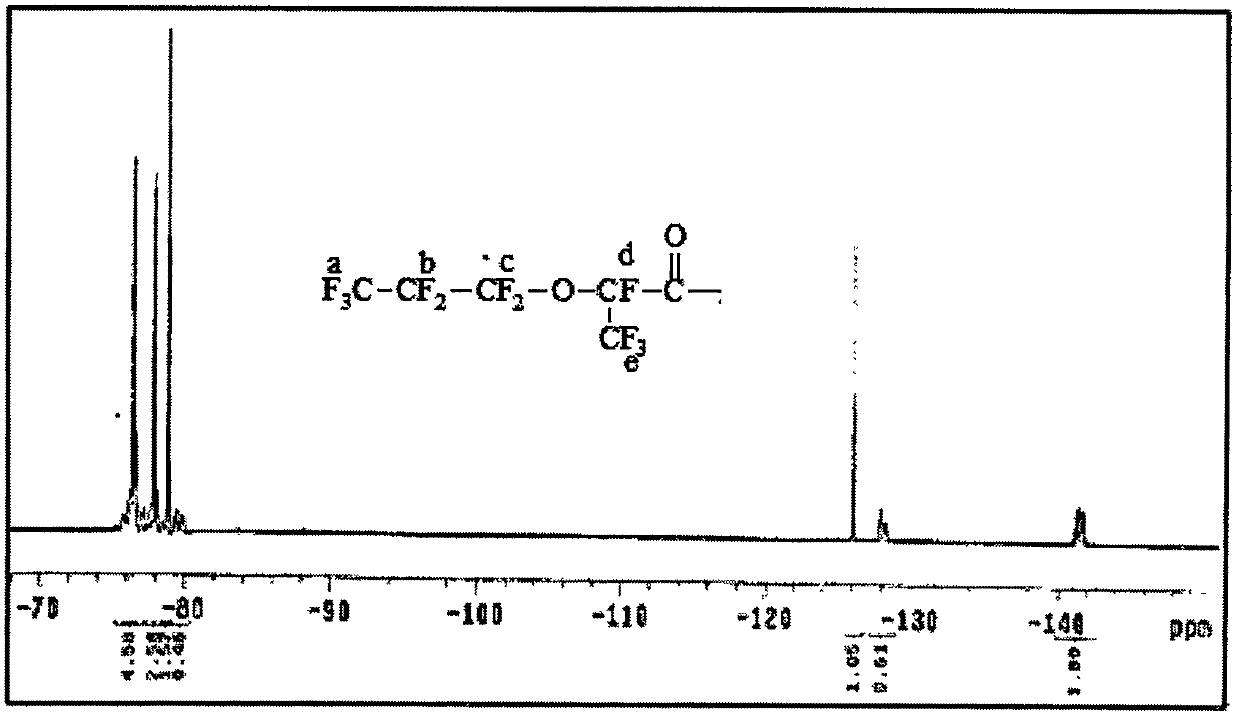

[0026] characterize

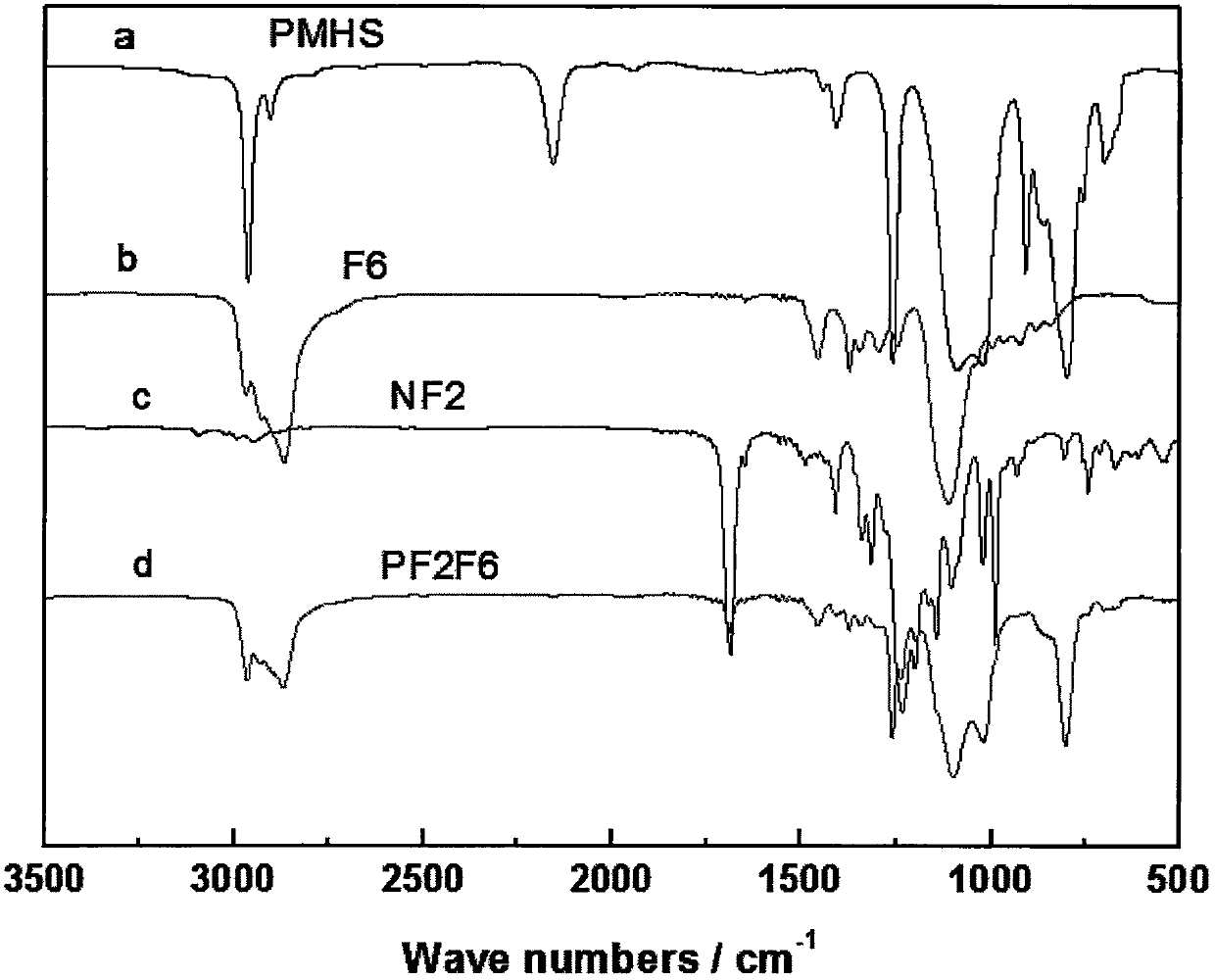

[0027] FT-IR characterization: the purified PF2F6 was pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com