Dry powder type immobilized lipase and production process thereof

A lipase and immobilized carrier technology, applied in the field of biomedicine, can solve the problem of lack of immobilized pig liver esterase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

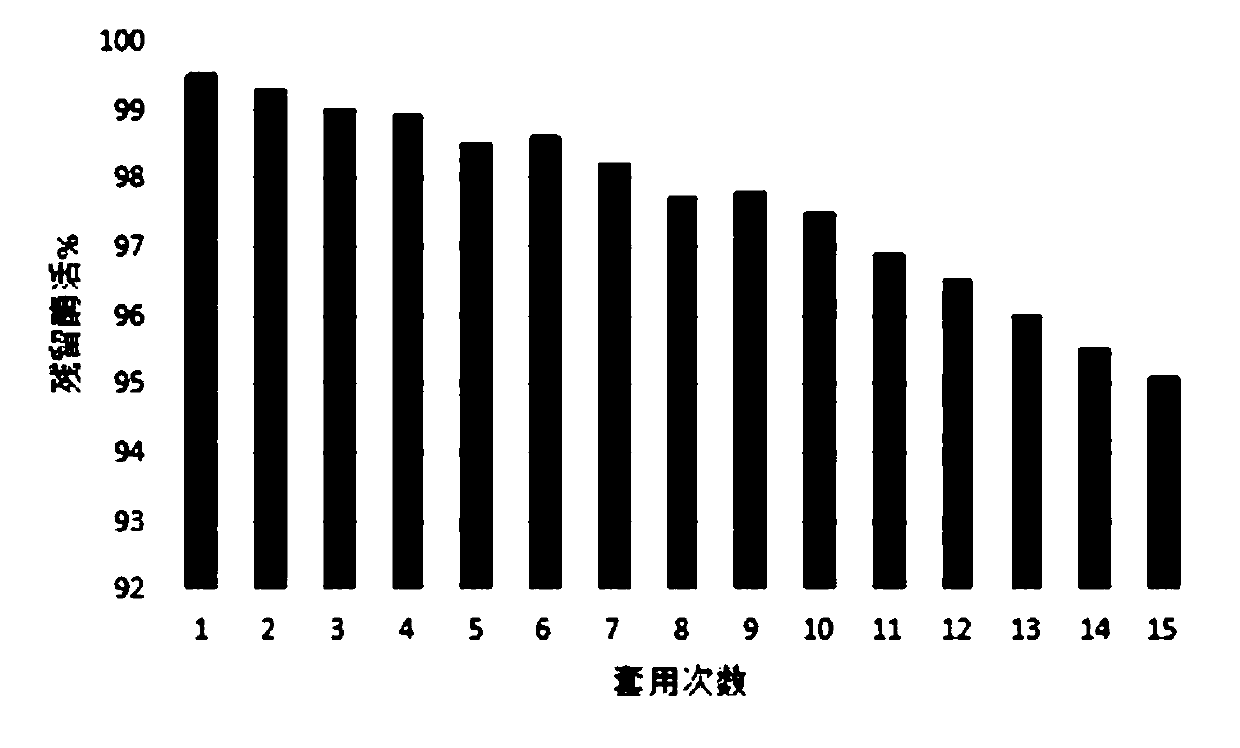

Embodiment 1

[0064] Dissolve porcine liver lipase (porcine liver esterase, purchased from Sigma, 15kU / g) in 50mM phosphate buffer (pH 7.5, specific enzyme activity of enzyme solution is 100u / mL), according to the ratio of 20g resin / 100mL enzyme solution Join Lifetech TM ECR1030M resin (also known as ECR1030M resin, purchased from Purolite, with a water content of about 70%, the same below), was subjected to immobilization reaction. The immobilization conditions were 16°C, 120 rpm, stirring for 16 hours, and standing for 4 hours. The immobilized enzymes were collected and washed with tap water and 50 mmol / L, pH 7.5 phosphate buffer solution to remove impurities on the resin surface and weakly adsorbed enzymes. After vacuum filtration, samples were taken to measure moisture and enzyme activity respectively, the moisture content was 69%, the enzyme activity was 500u / g, and the enzyme activity yield was 100%. The water-containing immobilized enzyme obtained is further dried with an ebullatin...

Embodiment 2

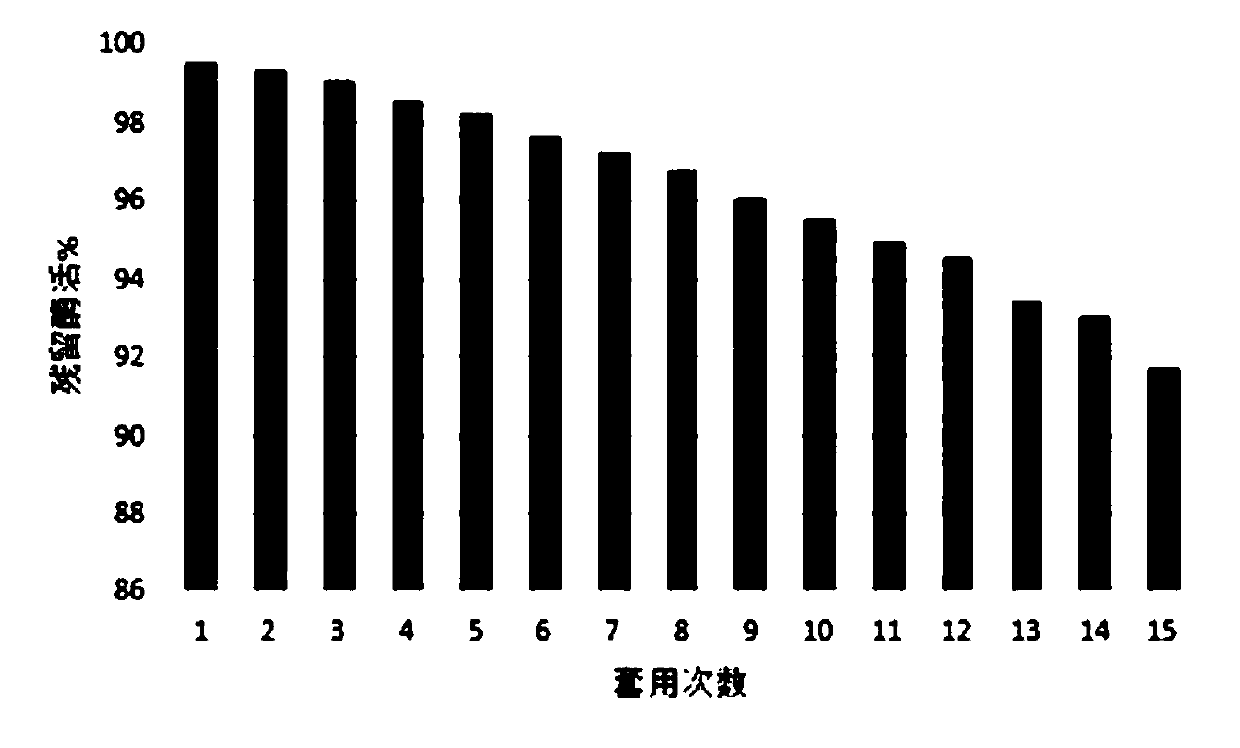

[0069] Dissolve porcine liver lipase (purchased from Sigma, 15kU / g) in 50mM phosphate buffer (pH 7, specific enzyme activity of the enzyme solution is 100u / mL), add Lifetech at a ratio of 15g resin / 100mL TM ECR1030M resin, for immobilization reaction. The immobilization conditions were 10°C, 150 rpm, stirring for 20 hours, and standing for 4 hours. The immobilized enzymes were collected and washed with tap water and 50mmol / L, pH7.5 phosphate buffer solution to remove impurities on the resin surface and weakly adsorbed enzymes. After vacuum filtration, samples were taken to measure water content and enzyme activity, the water content was 69%, the enzyme activity was 550u / g, and the enzyme activity yield was 82.5%. The obtained water-type immobilized enzyme was dried with a fluidized bed, the temperature of the air inlet of the fluidized bed was 35°C, the temperature of the air outlet was 25°C, and the drying time was 20min to obtain 8.5g of immobilized enzyme with a moisture c...

Embodiment 3

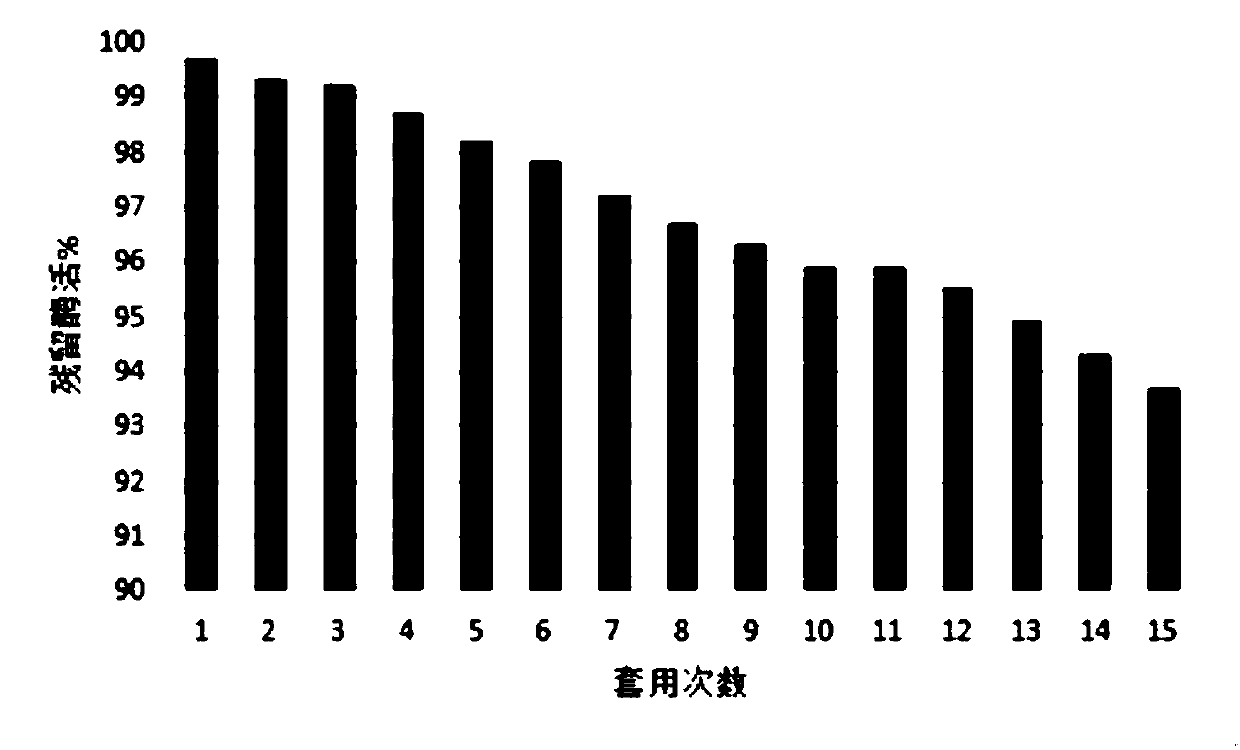

[0072] Dissolve porcine liver lipase (purchased from Sigma, 15kU / g) in 50mM phosphate buffer (pH 7.5, the specific enzyme activity of the enzyme solution is 100u / mL), add Lifetech at a ratio of 18g resin / 100mL TM ECR1030M resin, for immobilization reaction. The immobilization conditions were 15°C, 100 rpm, stirring for 20 hours, and standing for 5 hours. The immobilized enzymes were collected and washed with tap water and 50mmol / L, pH7.5 phosphate buffer solution to remove impurities on the resin surface and weakly adsorbed enzymes. After vacuum filtration, 18.5 g of wet immobilized enzyme was obtained, the water content was 69%, the enzyme activity was 530u / g, and the enzyme activity yield was 95.4%. The obtained water-containing immobilized enzyme is dried with a fluidized bed, the temperature of the air inlet of the fluidized bed is 40°C, the temperature of the air outlet is 25°C, and the drying time is 15min. The measured moisture content is 45%, and the enzyme activity i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com